Method for producing powdered rock phosphate balls by using powdered rock phosphate

A technology of phosphate rock powder and phosphoric acid, which is applied in the field of mineral processing, can solve problems such as low utilization rate and waste of raw ore, and achieve the effects of improving grade, reducing coke consumption, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

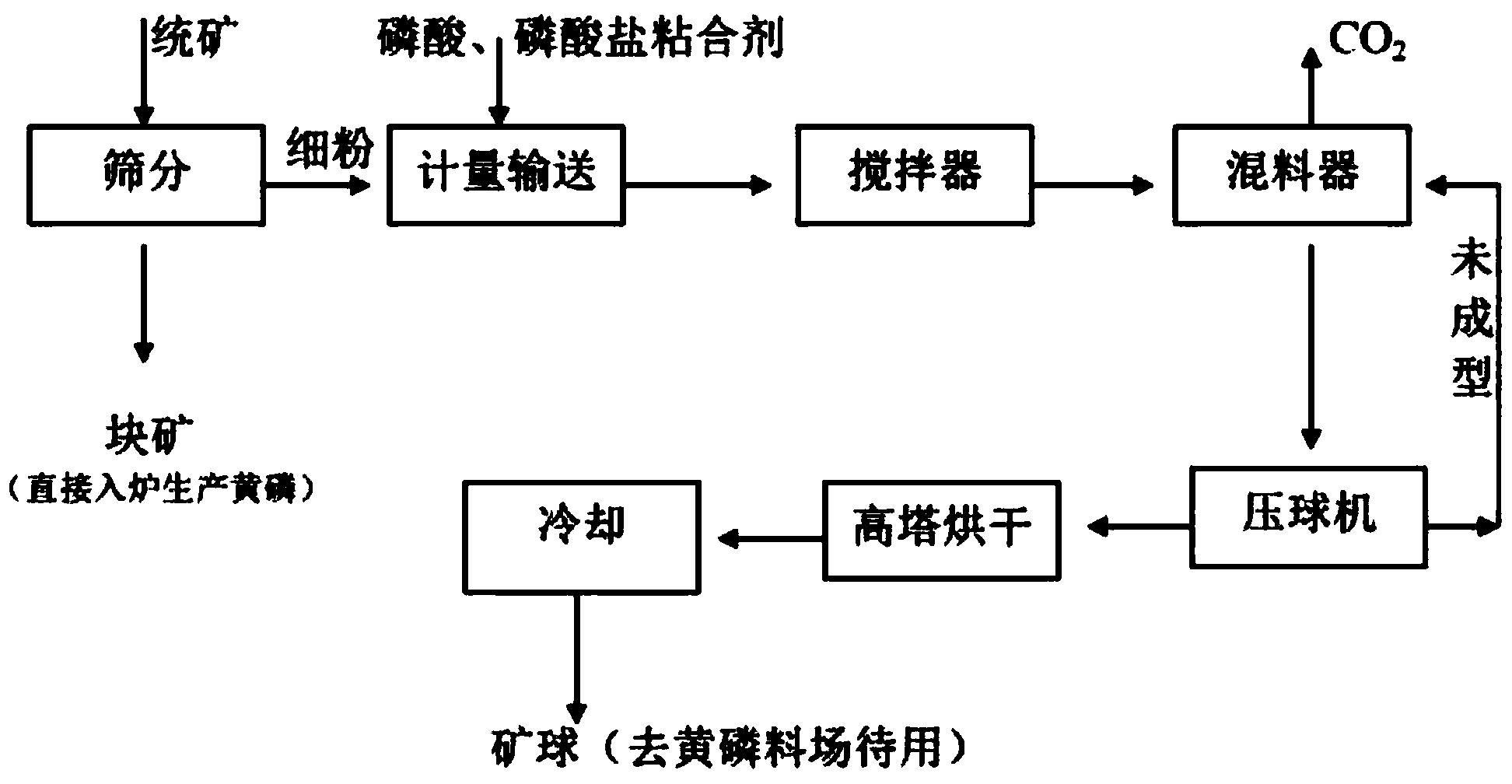

[0030] A kind of method utilizing phosphate rock powder to produce phosphate rock powder ball, comprises the following steps (as figure 1 shown):

[0031] (1) Screening: The phosphate rock powder screened by the production enterprise or the remaining mineral powder produced in the mine concentrate is screened with a 2-mesh screen. The massive mineral material is directly used for the production of yellow phosphorus. The screened powder The material then enters the batching step;

[0032] (2) Batching: carry out batching by 100 parts of phosphate rock powder, 2 parts of phosphoric acid and 0.5 part of phosphate binder, then drop into agitator and stir evenly, the mass percentage concentration of phosphoric acid is 10%, and phosphate binder is magnesium phosphate;

[0033] (3) Mixing: The evenly stirred mixture is transported into the double-roller mixer for full mixing, so that the CO in the mixture 2 freed;

[0034] (4) Ball briquetting: send the uniformly mixed powder int...

Embodiment 2

[0038] A kind of method utilizing phosphate rock powder to produce phosphate rock powder ball, comprises the following steps (as figure 1 shown):

[0039] (1) Screening: use 10-mesh sieve to screen the phosphate rock powder screened by the production enterprise or the remaining mineral powder produced in the mine. The material then enters the batching step;

[0040] (2) Batching: carry out batching according to 100 parts of phosphate rock powder, 5 parts of phosphoric acid and 1 part of phosphate binder, then drop into the stirrer and stir evenly, the mass percentage concentration of phosphoric acid is 30%, and phosphate binder is Magnesium phosphate and calcium phosphate;

[0041] (3) Mixing: The evenly stirred mixture is transported into the double-roller mixer for full mixing, so that the CO in the mixture 2 freed;

[0042] (4) Ball briquetting: send the uniformly mixed powder into the briquette machine to briquette under a pressure of 100 tons, and the unformed mixture...

Embodiment 3

[0046] A kind of method utilizing phosphate rock powder to produce phosphate rock powder ball, comprises the following steps (as figure 1 shown):

[0047] (1) Screening: The phosphate rock powder screened by the production enterprise or the remaining mineral powder produced by the mine on the mine is screened with a 15-mesh screen. The massive mineral material is directly used for yellow phosphorus production. The screened powder The material then enters the batching step;

[0048] (2) Batching: carry out batching by 100 parts of phosphate rock powder, 8 parts of phosphoric acid and 2 parts of phosphate binder, then drop into agitator and stir evenly, the mass percentage concentration of phosphoric acid is 50%, phosphate binder is Magnesium phosphate and aluminum phosphate;

[0049] (3) Mixing: The evenly stirred mixture is transported into the double-roller mixer for full mixing, so that the CO in the mixture 2 freed;

[0050] (4) Ball briquetting: send the uniformly mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com