Flange hoisting device

A hoisting device and flange technology, applied in the field of hoisting equipment, can solve the problems of limited scope of application, inconvenient preparation of hoisting tools, low construction efficiency, etc., and achieve a simple and reasonable overall structure design, safe and reliable hoisting operation, and ideal use effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

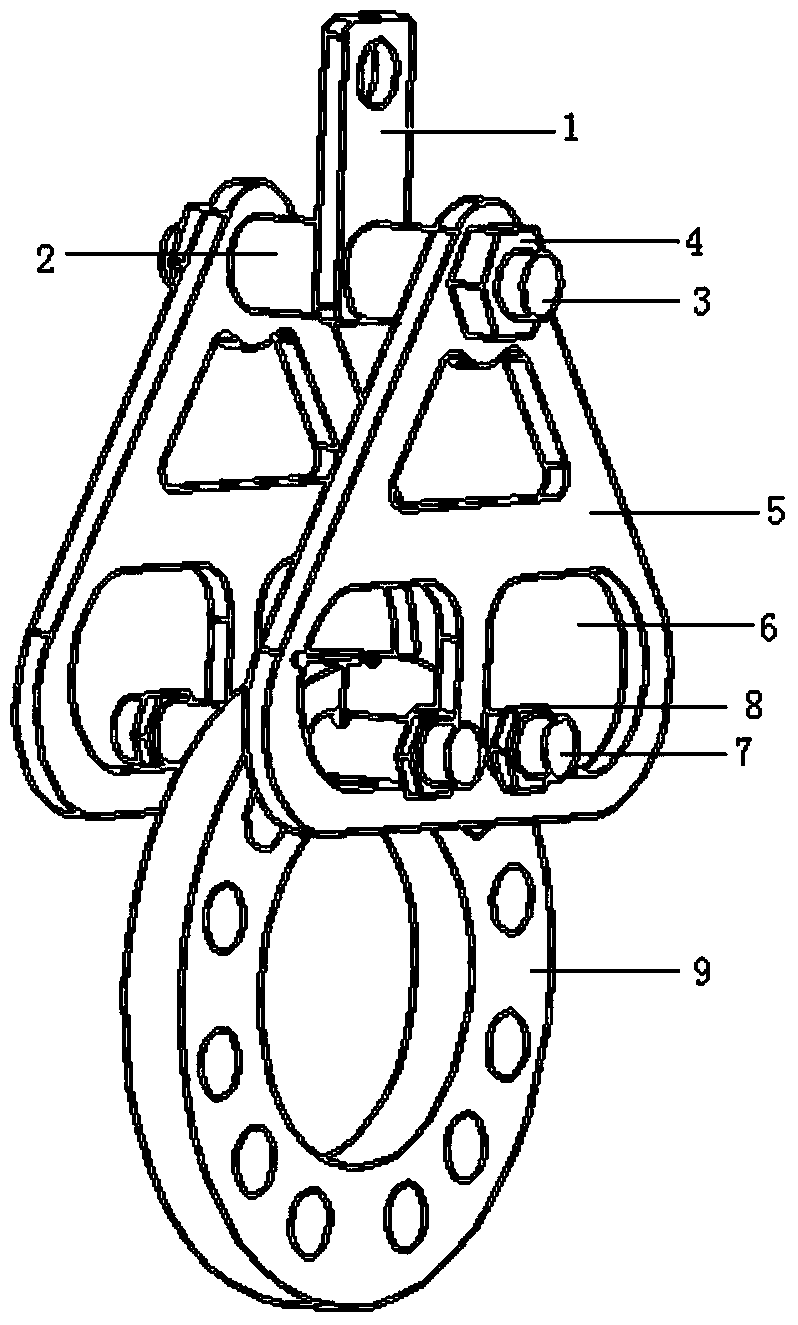

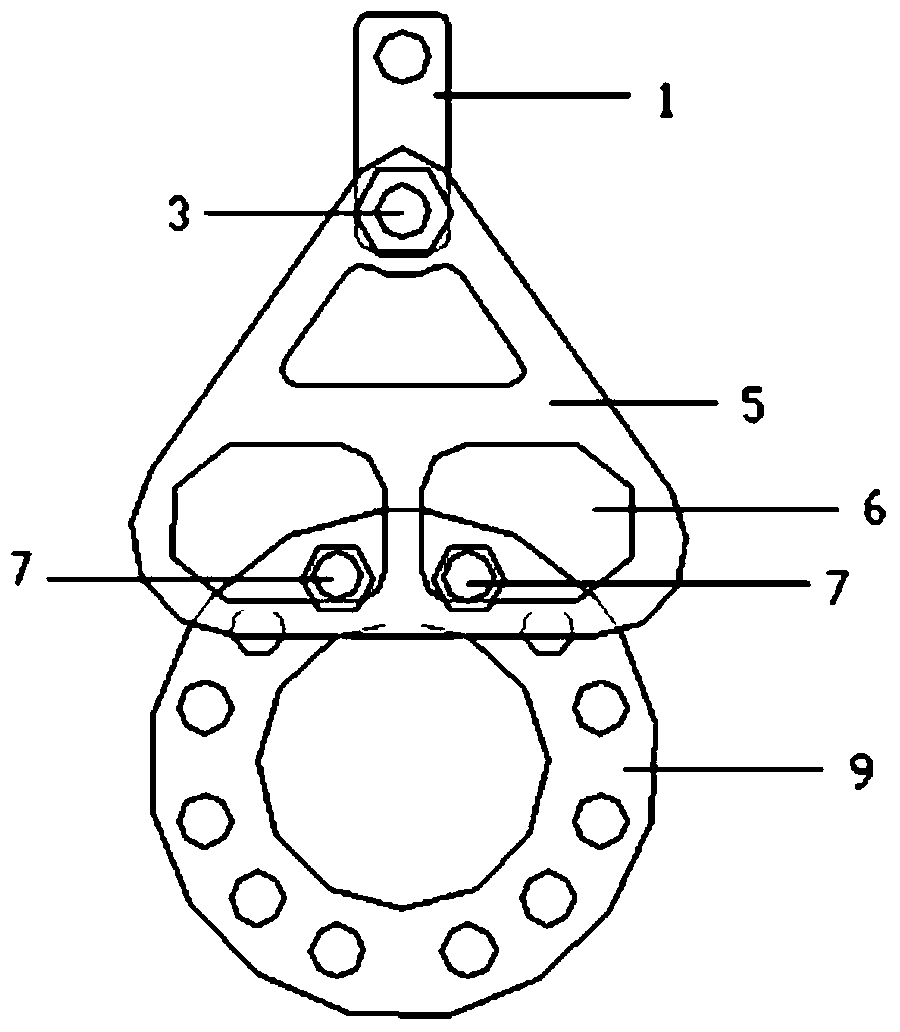

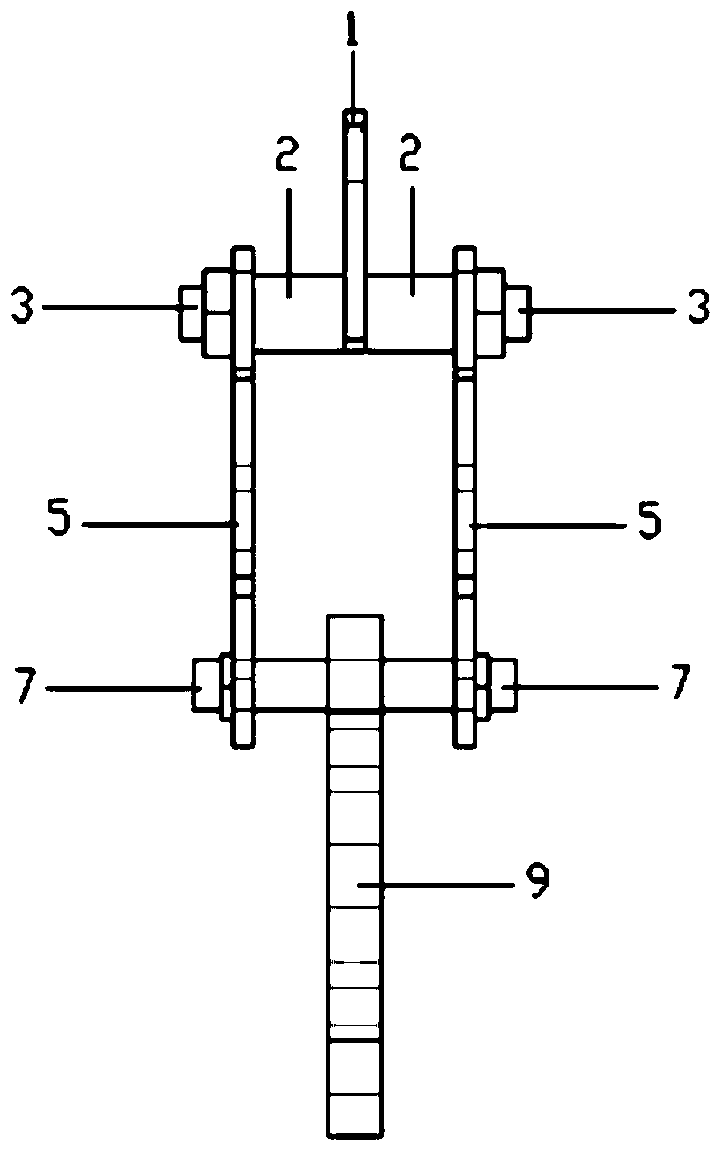

[0015] Such as Figure 1 to Figure 4 As shown, the flange lifting device of the present invention comprises two lifting ear plates 5 and a lifting point orifice 1, the plate surfaces of the two lifting lugs 5 and one lifting point orifice 1 are arranged in parallel to each other and pass through The liaison shaft 3 is assembled together, and the two hoisting lug plates are respectively located under the two sides of the hoisting point orifice plate, and the distance between the hoisting point orifice plate and the two hoisting lug plates is kept the same by passing through the short tube 2 on the liaison shaft The two ends of the connecting shaft 3 are respectively worn on the outer sides of the two hoisting lugs 5, and are fastened with nuts 4 to prevent the hoisting lugs 5 from falling off.

[0016] Such as Figure 1 to Figure 4 As shown, the flange lifting device of the present invention, wherein: the lifting point hole plate 1 is a steel plate, the upper part of the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com