Cloth paving machine and cloth feeding cradle device thereof

A cloth spreading machine and cloth feeding technology, which is applied in the direction of transportation and packaging, spreading thin soft materials, winding strips, etc., can solve the problems of easy deformation of rolled cloth and uneven cloth, and achieve simple structure and easy installation , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

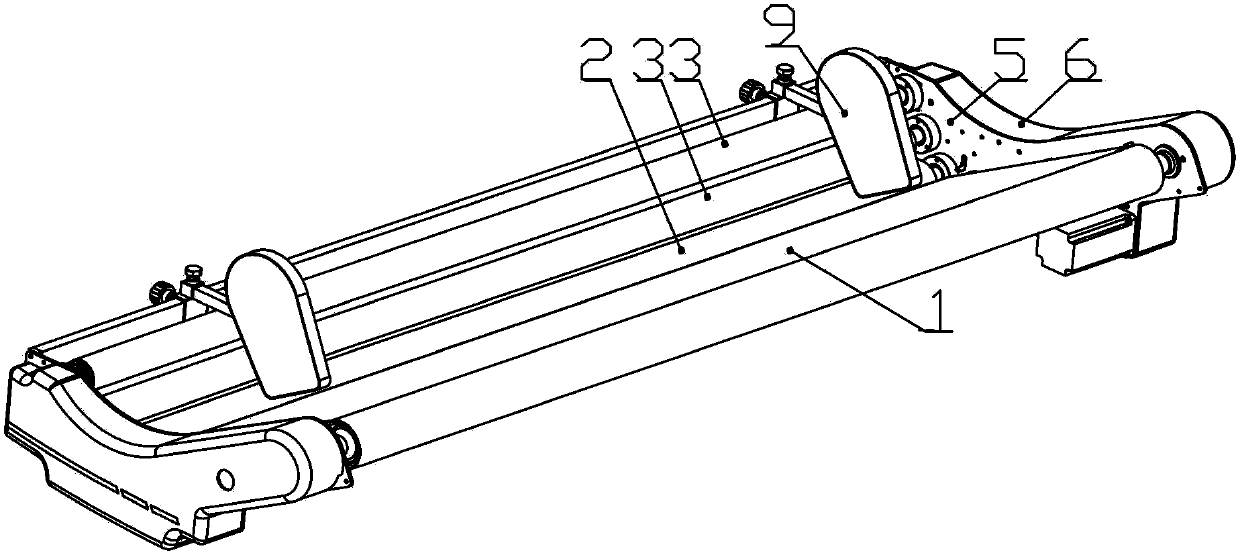

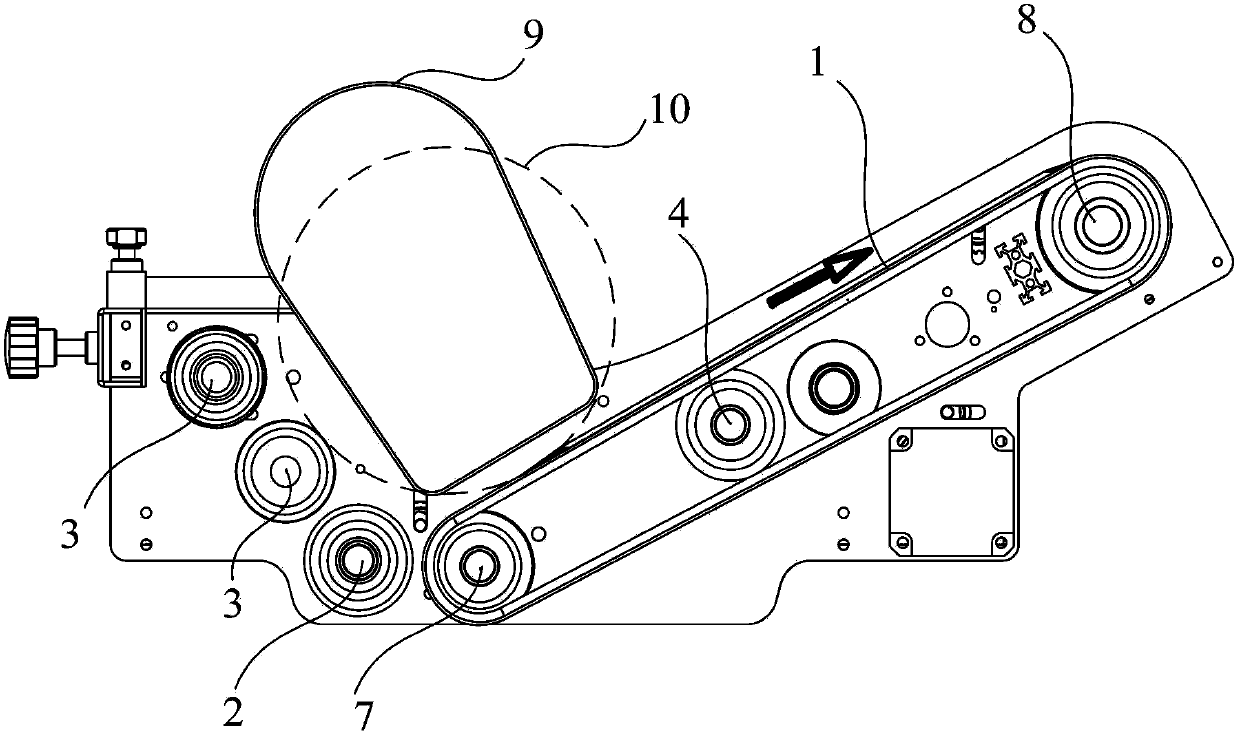

[0035] Such as image 3 As shown, the cloth feeding cradle device of the spreading machine of the present invention includes: two mounting plates 1 arranged at intervals, a support rod (not shown in the figure) horizontally arranged between the two mounting plates 1, and a set of respectively The baffle assembly 8 affixed to the support rod at intervals, the cloth feeding cradle device of the spreading machine also includes:

[0036] A support roller 3, the support roller 3 is located on one side of the support rod;

[0037] A driving roller 4, the center of the driving roller 4 is on the same horizontal line as the core of the support roller 3;

[0038] A cloth feed roller 6, the center of the cloth feed roller 6 is higher than the core of the support roller 3, and placed on the side of the cloth feed direction; and

[0039] A first limit roller 5, the first limit roller 5 is above the driving roller. The supporting roller 3, the driving roller 4, the cloth feeding roller ...

Embodiment 2

[0046]The difference between this embodiment and Embodiment 1 is that the cloth feeding cradle device of the spreading machine also includes a second limit roller, which is located between the cloth feeding roller and the supporting roller, and The core of the second limiting roller is lower than the feeding roller and higher than the supporting roller.

[0047] By setting the second limit roller, the roll cloth can be securely sandwiched above the supporting roller and the driving roller, ensuring uniform rolling of the roll cloth during feeding.

[0048] Other parts of this embodiment are the same as Embodiment 1.

Embodiment 3

[0050] The difference between this embodiment and Embodiment 2 is that the cloth feeding cradle device of the spreading machine in this embodiment also includes a driven roller 7'.

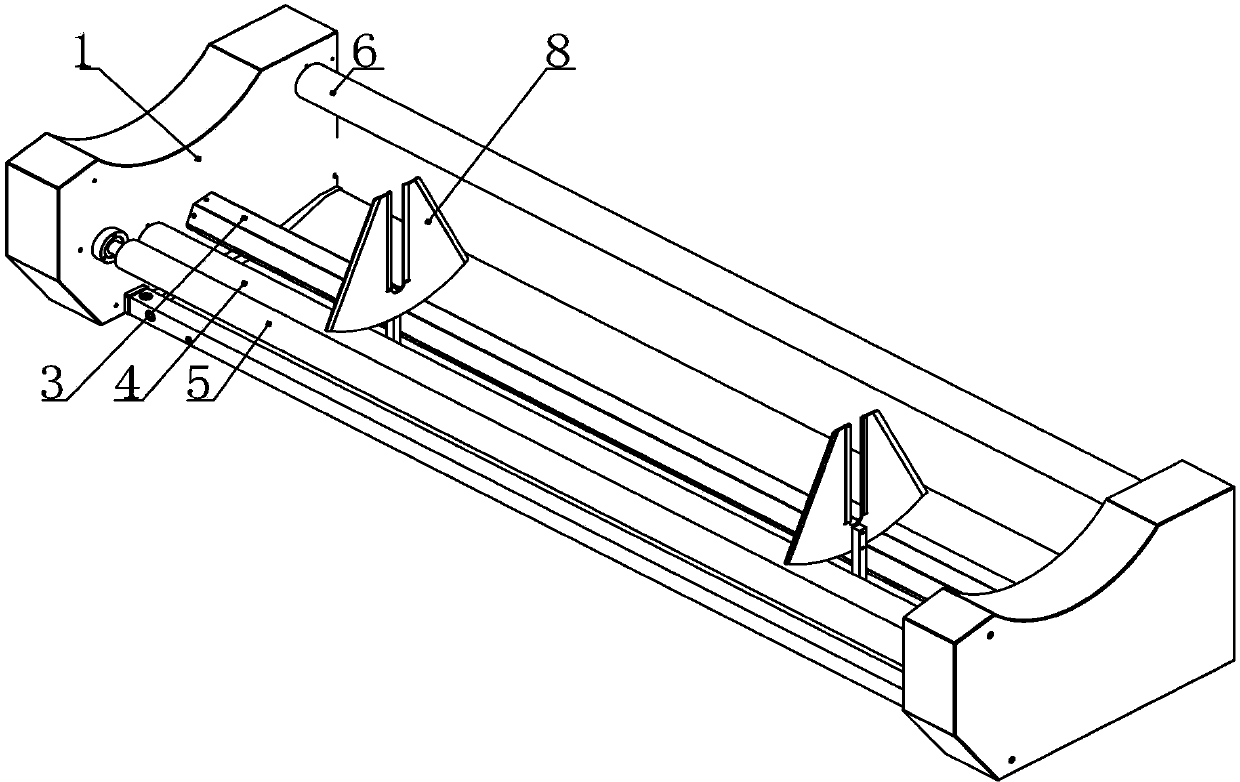

[0051] Figure 4~Figure 6 The structure of the cloth feeding cradle device of the cloth spreading machine according to the present invention is shown. Such as Figure 4~Figure 6 As shown, the cloth feeding cradle device of the spreading machine of the present invention includes: two mounting plates 1, two casings, a support roller 3, such as a hexagonal roller; a driving roller 4, a first limiter A positioning roller 5, a cloth feeding roller 6, a driven roller 7', a second limiting roller 7, a baffle assembly 8, and a support tube 9. The two ends of the hexagonal roller are movably embedded on two mounting plates 1, the driving roller 4, the first limit roller 5, the cloth feeding roller 6, the driven roller 7', and the two ends of the support tube 9 are also All are movable respectively arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com