Layer pad production method

A production method and surface layer technology, applied in the direction of layered products, etc., can solve problems such as inconvenience and sliding, and achieve the effect of enhancing slip resistance, various uses, and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention is made according to the following process.

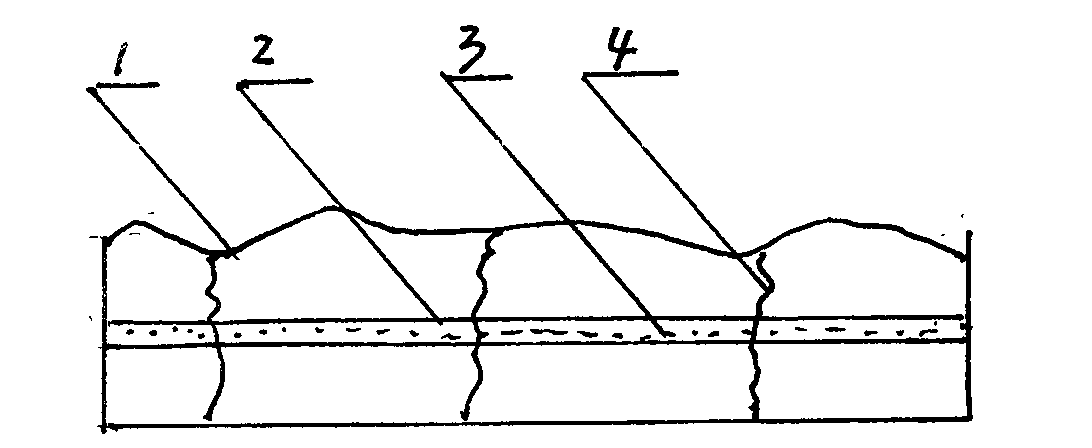

[0014] The present invention is described further below, sticking adhesive (3) tightly between inner layer (2) and inner layer (2), pasting upper surface layer (1) outside again, inner layer (2) has multiple layers, surface layer (1) The upper layer is made of floc, such as made of cotton cloth or fiber. The bottom layer is a smooth surface.

[0015] Step 1. Overlapping the fabrics with preset layers, and bonding each adjacent two layers with an adhesive;

[0016] Step 2, sewing the bonded fabric;

[0017] Step 3. Cutting the sewn fabric into a preset pattern;

[0018] Step 4. Peel off one or more layers of fabric on one side of the fabric.

[0019] Step 5. Sew another layer of fabric on the other side of the fabric.

[0020] Step 6, deburring the loop edge of the fabric.

[0021] Step 7, make a smooth layer on the surface of the fabric.

[0022] Step 8, apply top glue on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com