A method and device for enlarging the flow capacity of an oil inlet channel of an oil cylinder

A technology of oil inlet channel and flow capacity, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., which can solve the problems of reduced strength and life of the master cylinder, and achieve shortening the transformation cycle and saving transformation cost, and the effect of reducing the risk of renovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

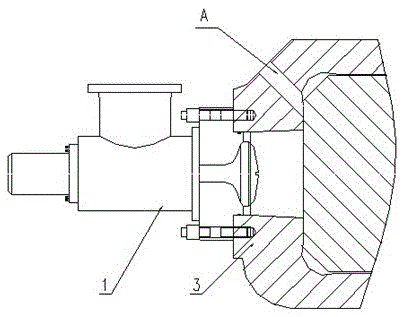

[0021] In the process of transforming the hydraulic machine, in order to overcome the conventional transformation method that destroys the strength of the main cylinder, the workload and difficulty in the transformation process, and avoid the problems of potential safety hazards in the future equipment work, the present invention provides a The method of increasing the flow capacity of the oil inlet channel of the oil cylinder is to connect the multi-channel flow-increasing connector 2 between the filling valve 1 and the master cylinder 3. The central part of the multi-channel increasing flow connector 2 is provided with an axial through hole 9, and the side The wall is provided with an oil delivery through hole 8; the axial through hole 9 communicates with the oil delivery through hole 8; The oil delivery through hole 8 communicates with the external pressure oil pipe.

[0022] Among them, the multi-channel flow-increasing connector 2 has sufficient strength, can withstand th...

Embodiment 2

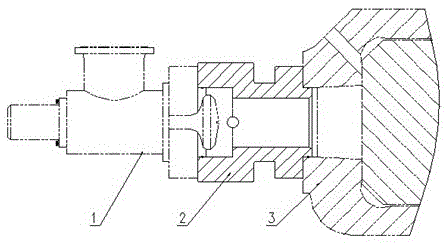

[0027] In order to realize embodiment 1 to increase the flow capacity of the oil inlet channel of the oil cylinder, this embodiment provides a method such as figure 2 and image 3 The shown device for increasing the flow capacity of the oil inlet channel of the oil cylinder includes a multi-channel flow-increasing connector 2, and the two ends of the multi-channel increasing flow connector 2 are respectively provided with ports connected to the filling valve 1 and the master cylinder 3. head, the center of the multi-channel flow increasing communicator 2 is provided with an axial through hole 9, and the side of the multi-channel increasing flow communicating device 2 is provided with an oil delivery through hole 8, and the axial through hole 9 and the oil delivery channel Holes 8 communicate with each other.

[0028] One end of the multi-channel flow-increasing connector 2 is connected to a flange, and the flange is provided with a via hole corresponding to the original thre...

Embodiment 3

[0031] In order to realize embodiment 1 to increase the flow capacity of the oil inlet channel of the oil cylinder, this embodiment provides a method such as Figure 4 The shown device for increasing the flow capacity of the oil inlet channel of the oil cylinder includes a multi-channel flow increasing connector 2, and the two ends of the multi-channel increasing flow connecting device 2 are respectively provided with terminals connected to the filling valve 1 and the master cylinder 3, The center of the multi-channel flow increasing communicator 2 is provided with an axial through hole 9, and the side of the multi-channel increasing flow communicating device 2 is provided with an oil delivery through hole 8, and the axial through hole 9 and the oil delivery through hole 8 phases are connected.

[0032] A fastener through hole is arranged axially in the multi-channel flow-increasing connector 2. The fastener through hole is consistent with the original through hole on the fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com