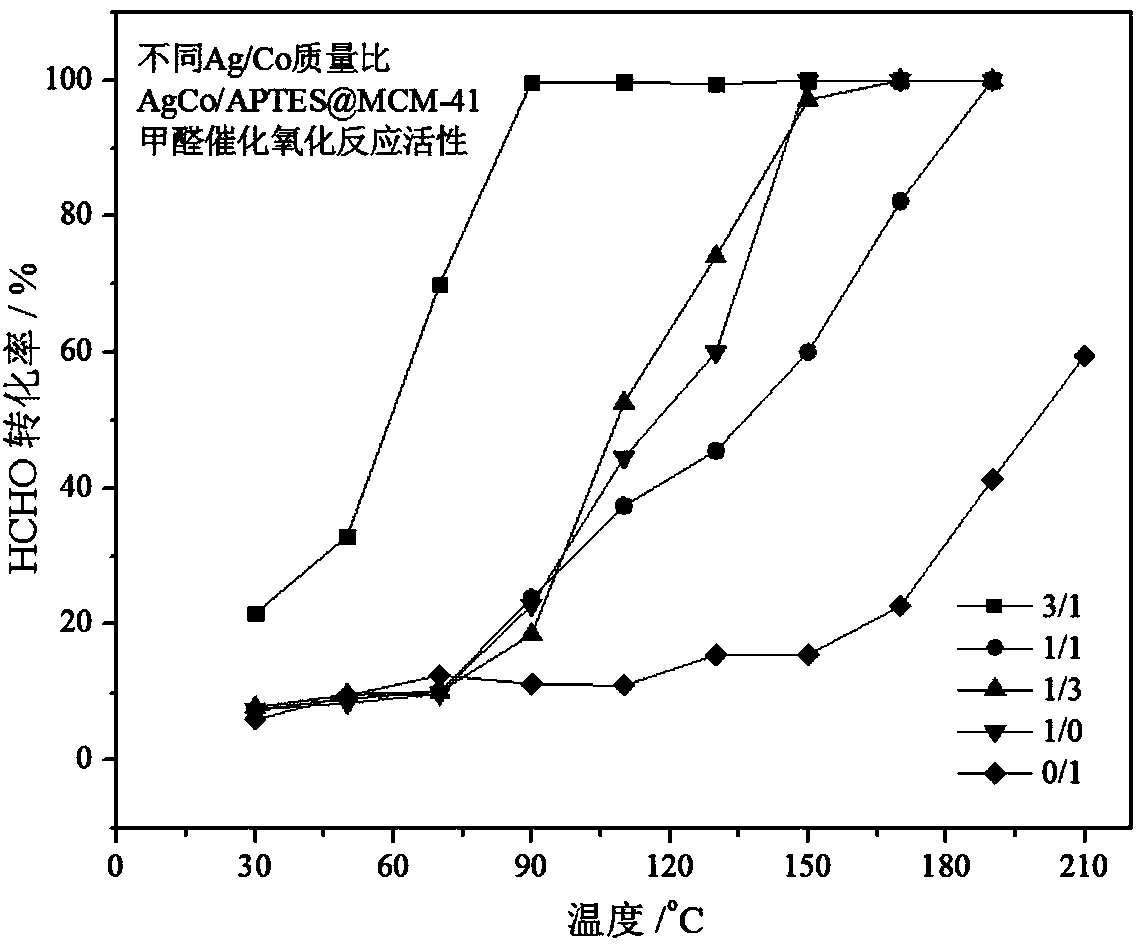

AgCo bimetallic catalyst with adsorption-catalysis double functions for use in removal of formaldehyde and preparation method thereof

A bimetallic catalyst and a technology for eliminating formaldehyde, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of catalyst formaldehyde conversion rate decline, etc., and achieve reduced application costs, low cost, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

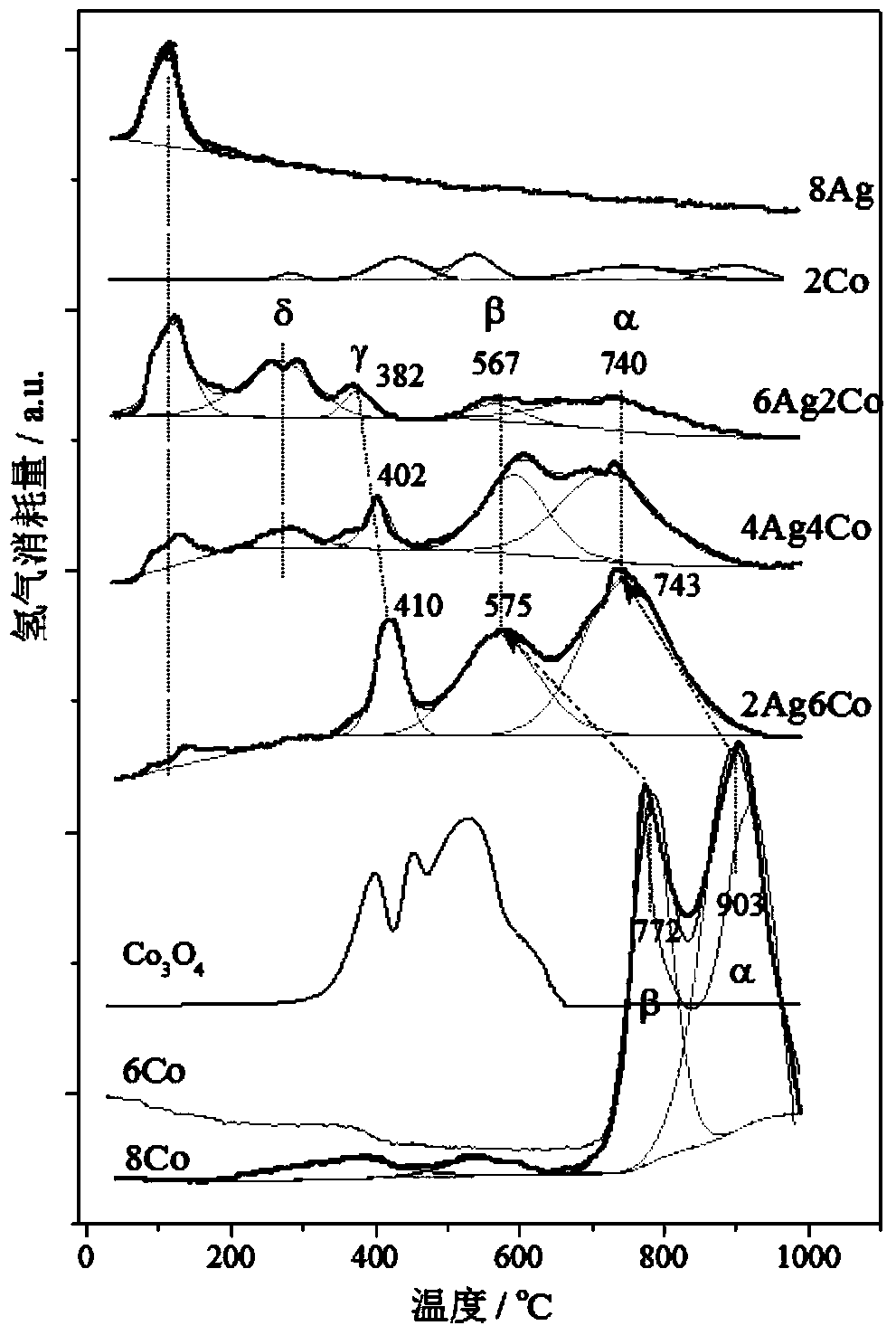

Embodiment 1

[0017] Condensate and reflux 2.0g MCM-41 and 10.0g APTES in 200mL of absolute ethanol at 80-100°C for 24h, centrifuge, wash, dry at 80°C for 24h, and calcinate at 500°C for 6h to obtain APTESMCM-41 sample; weigh 1.0 g APTESMCM-41 in 40mL deionized water to obtain APTESMCM-41 aqueous solution, stirred at room temperature for 15min, added 0.0945g AgNO 3 , stirred at room temperature for 15 minutes, and quickly added 10 mL of 2M NaBH 4 The solution was chemically reduced, continued to stir at room temperature for 30 min, and then centrifuged and washed to obtain a 6% Ag / APTESMCM-41 sample; the washed Ag / APTESMCM-41 sample was dissolved in 40 mL of deionized water and stirred at room temperature for 15 min, followed by adding 0.099 g Co(NO 3 ) 2 ·6H 2 O, stir at room temperature for 15min, continue to add 10mL of 2M NaBH rapidly 4 The solution was chemically reduced, continued to stir at room temperature for 30 minutes, and then centrifuged and washed; finally, the centrifuged ...

Embodiment 2

[0019] According to the preparation method of Example 1, 0.126g AgNO 3 Added to APTESMCM-41 sample without adding Co(NO 3 ) 2 ·6H 2 O, the rest of the steps remained the same to obtain a 8Ag0Co / APTESMCM-41 sample (the mass fraction of Ag was 8%, the mass fraction of Co was 0%, and the Ag / Co mass ratio was 1 / 0).

Embodiment 3

[0021] According to the preparation method of Example 1, 0.396g Co(NO 3 ) 2 ·6H 2 O was added to the APTESMCM-41 sample without the addition of AgNO 3 , and the rest of the steps remain the same to obtain the 0Ag8Co / APTESMCM-41 sample (the mass fraction of Ag is 0%, the mass fraction of Co is 8%, and the Ag / Co mass ratio is 0 / 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com