Measuring Device, Machine And Method For The Tobacco Processing Industry

A measuring device and technology in the processing industry, applied in the field of rod-shaped products or material rods, and filter rods, can solve the problems of not being able to put them in the center, and achieve the effect of fast position determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

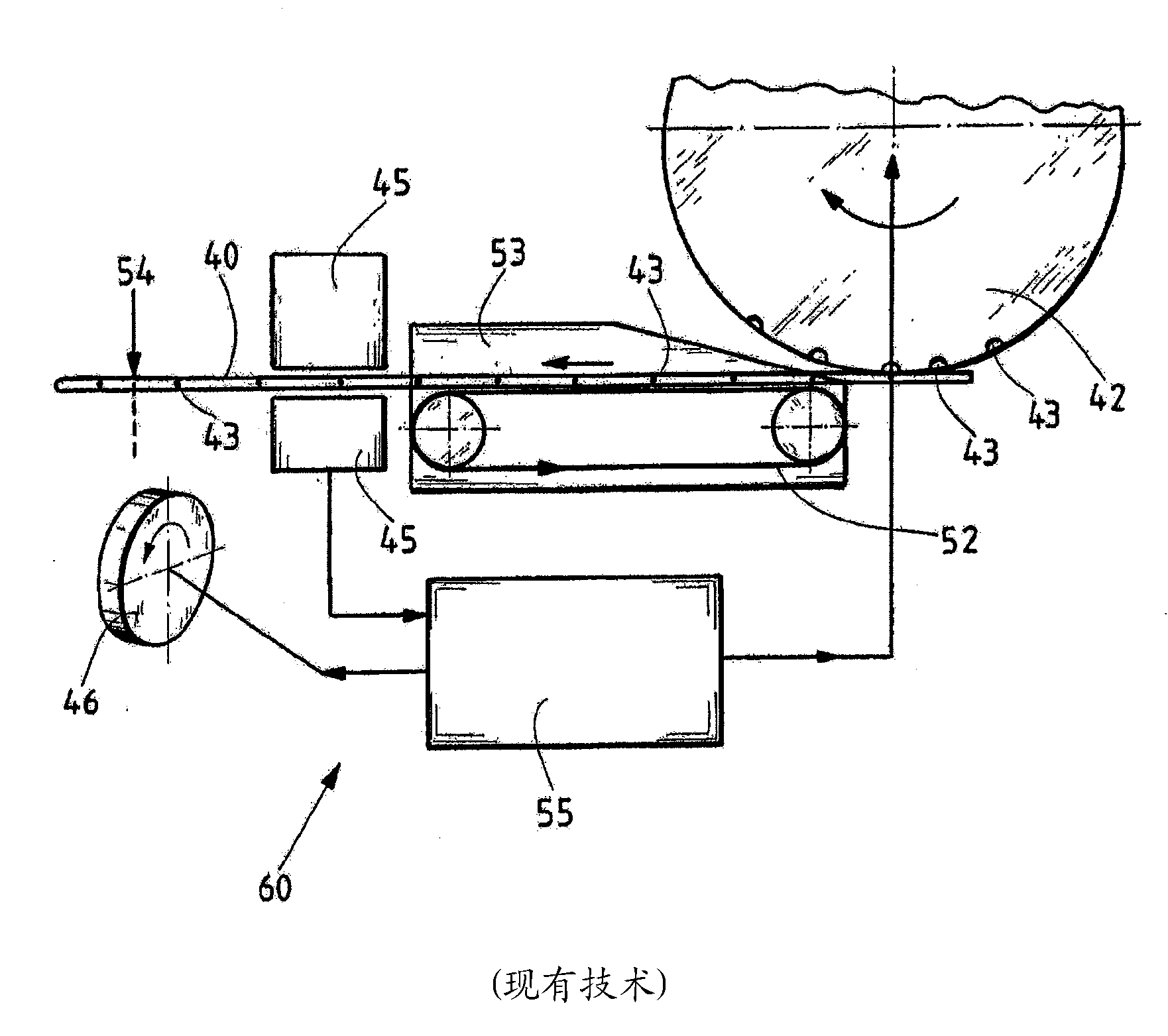

[0040] figure 1 A part of a filter rod making machine known, for example, from EP 2 243 385 A2 is shown schematically. Filter rod 40 is along longitudinal axis 57 i.e. longitudinally axially in figure 1 Convey from right to left. In the filter rod 40 , two pod shells 43 and 44 are each inserted or inserted into the filter rod at substantially equal distances from the other two pod shells 43 and 44 by means of an insertion wheel 42 . The filter rod 40 then has side-by-side pod shells 43 and 44 between which filter tows may also be arranged.

[0041] The filter rod 40 with the pods 43 and 44 then passes through a microwave resonator 45 in which, inter alia, the quality of the filter rod and the filling of the pods 43 and 44 are checked. The form of a microwave resonator is known, for example, from DE 198 54 550 B4, the details of which are hereby cited. The microwave resonator 45 is also used to determine the position of the longitudinal axis of the pod shells 43 and 44 . F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com