Extrusion machine with improved temperature control system

A technology of extruder and extrusion cylinder, applied in the field of extruder with improved temperature control system, which can solve the problems of inaccurate measurement of the temperature of processed materials, lower efficiency of temperature adjustment system, low efficiency of cooling system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

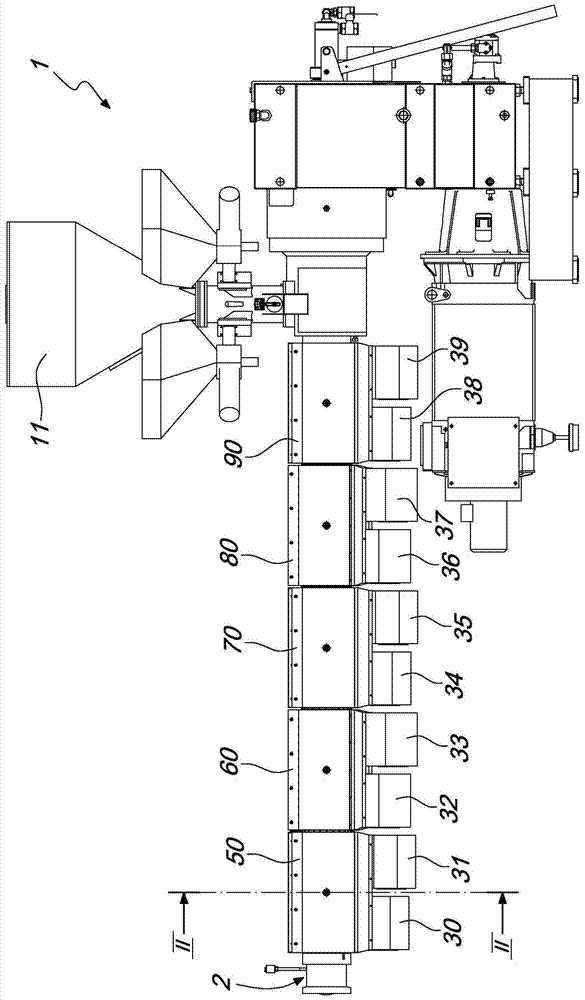

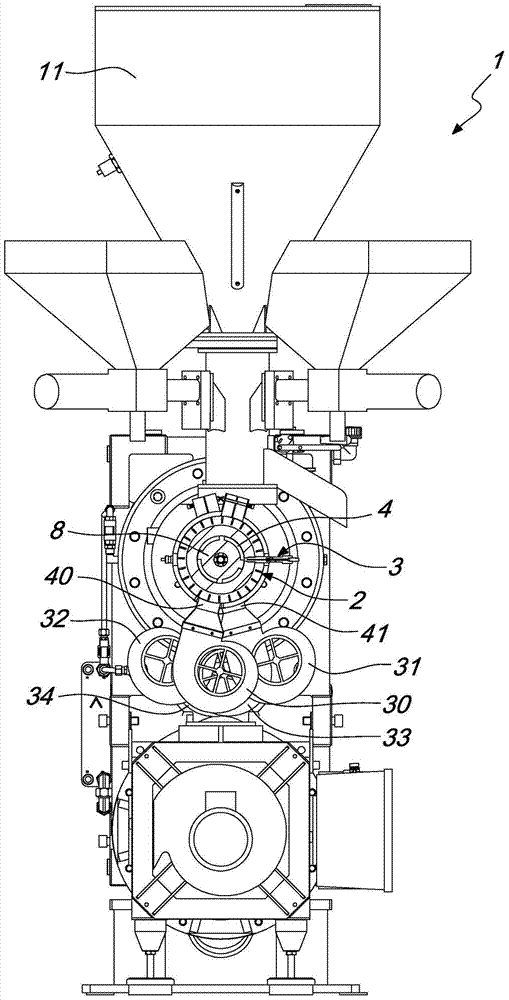

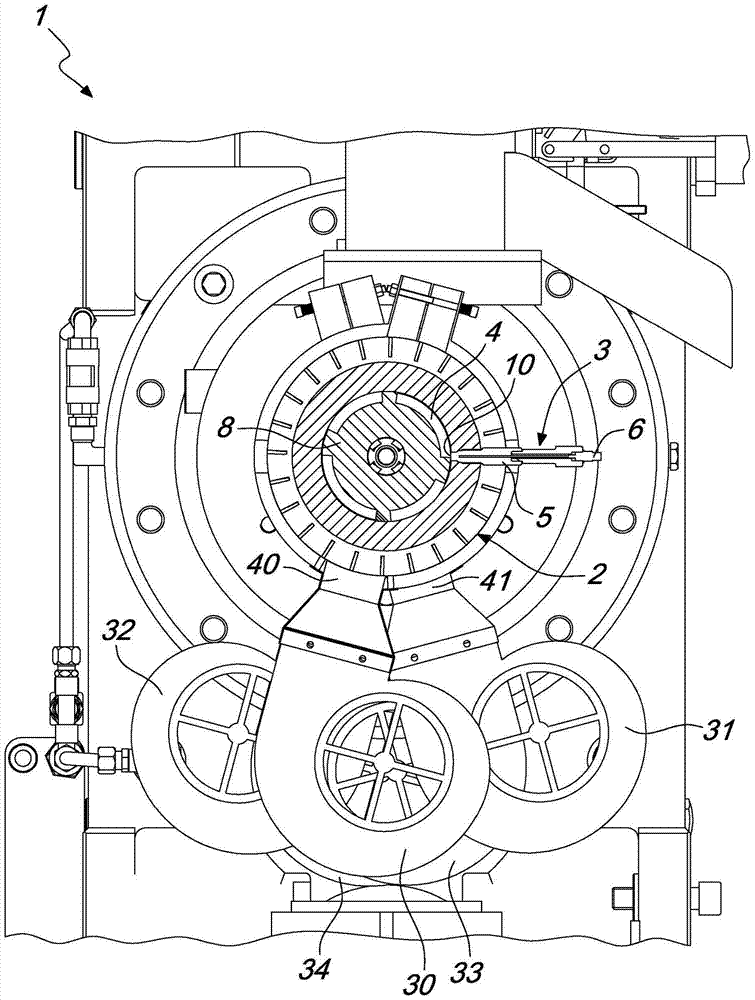

[0021] With reference to the figures referred to, an extruder of improved construction, in particular for thermoplastic compounds, generally indicated by the reference numeral 1 , comprises: an extrusion barrel 2 hollow inside; at least one heating element, conveniently provided by adjacent one or more heaters arranged on the outer surface of the extrusion barrel 2; at least one cooling fan 30-39 engaging the outer surface of the extrusion barrel 2; and at least one temperature probe 3 inserted into the extrusion barrel 2 middle.

[0022] According to the invention, the temperature probe 3 faces directly and internally the cavity 4 of the extrusion barrel 2 and, in particular, in the case of an extruder of the single-screw type shown in the drawings, the temperature probe 3 Facing the cavity that occurs between the inner surface of the extrusion barrel 2 and the outer surface of the extrusion screw 8 .

[0023] The extruder 1 is also suitable for processing different types of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com