Method for reshaping a turbomachine blade that has at least one zone that has become deformed using peening

An area and blade technology, applied in the maintenance field of any turbine engine blade, can solve problems such as difficult implementation, no repair of IBR, etc., and achieve the effect of restoring shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

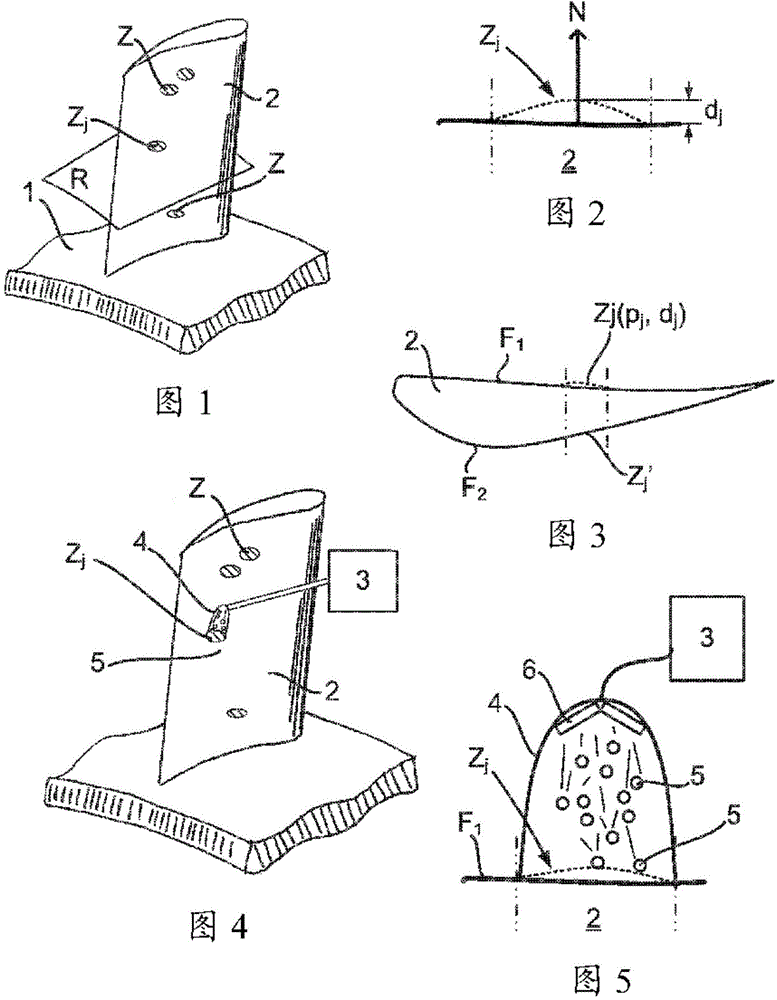

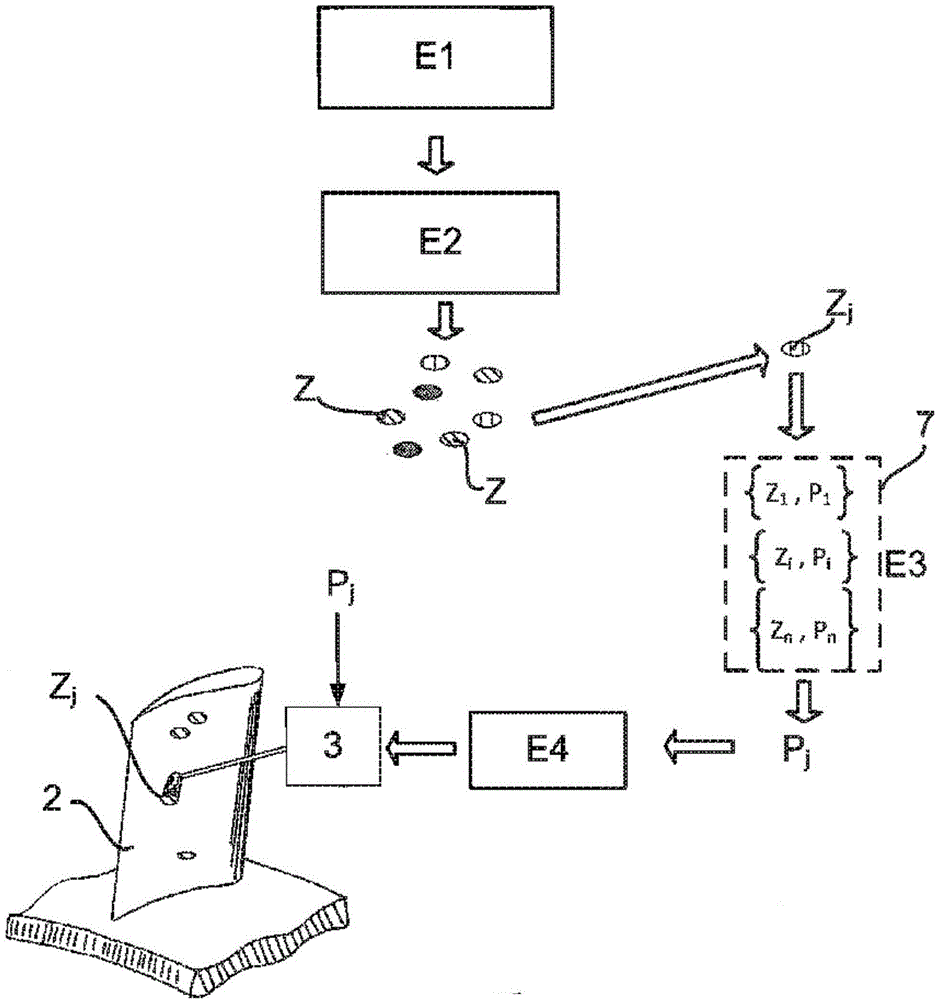

[0038] It should be noted that the accompanying drawings disclose the invention in a detailed manner to carry it out, which drawings can of course be used to give a better definition of the invention where appropriate.

[0039] The invention represents the reshaping of turbine engine blades belonging to an integral blade rotor (IBR) of a turbojet engine, but the following description applies of course to any turbine engine blade.

[0040] figure 1 Shown is a part IBR of an axial turbojet with an axially extending annular rim 1 and radially extending vanes 2 . For clarity, figure 1 Only blade 2 of the IBR is shown. During the operation of the aircraft, the blades 2 of the IBR deform, which affects their aerodynamic performance. In order to detect the deformation of the blade 2 to be reshaped, several manual or automatic methods are possible.

[0041] Such as figure 1 As shown in , the blade 2 to be reshaped comprises several deformation zones Z that impair the aerodynamic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com