Superimposed column type bituminous pavement energy harvesting device

A technology for energy harvesting and asphalt pavement, which is applied in the direction of electric energy storage systems, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problems of road energy harvesting, low energy conversion efficiency, Problems such as small energy transmission coefficient, to achieve good deformation synergy, high energy conversion efficiency, and small difference in stiffness change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

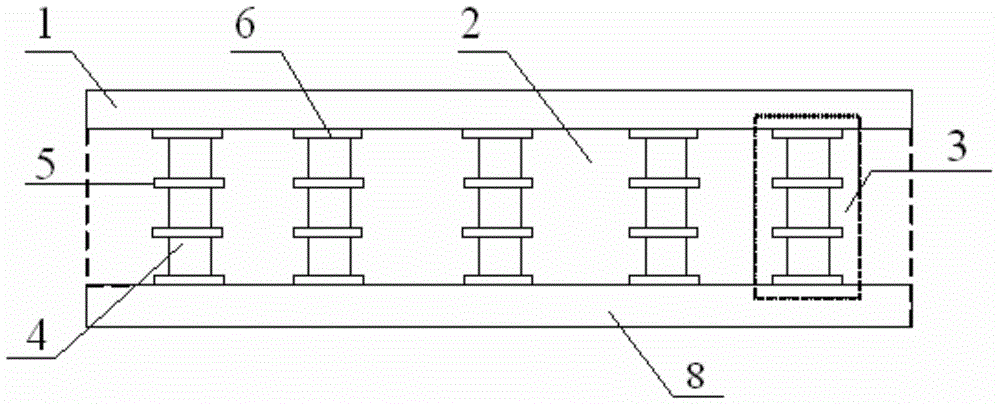

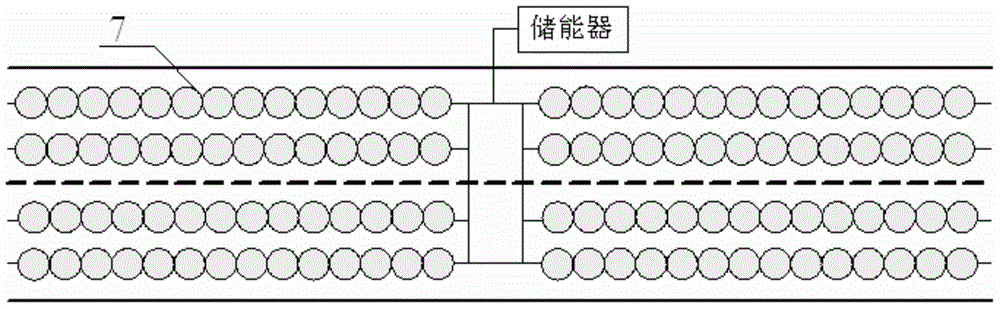

[0040] Such as figure 1 Shown is a stacked column type asphalt pavement energy harvesting device, the upper surface top plate 1 and the lower surface top plate 8 are circular with a radius of 11 cm and a thickness of 5 mm. The size of the encapsulation layer 2 is a cylinder with a base radius of 11 cm and a height of 1.6 cm filled with asphalt sand. Between the top plate 1 on the upper surface and the top plate 8 on the lower surface, 21 piezoelectric ceramic column units 3 are densely arranged, wherein the piezoelectric ceramic column unit 3 is formed by stacking three piezoelectric ceramic column bodies 4, and the piezoelectric ceramic column units 3 and A metal sheet 5 is directly provided on the surface top plate, and a metal sheet 5 is provided between each piezoelectric ceramic column body 4 . The piezoelectric ceramic column body 4 , the top plate 1 on the upper surface and the top plate 8 on the lower surface are all bonded by the adhesive layer 6 . The bonding layer...

Embodiment 2

[0046] Such as figure 1 Shown is a stacked column type asphalt pavement energy harvesting device (except that the piezoelectric ceramic column unit 3 is composed of four piezoelectric ceramic column bodies 4, and the other structures are the same as figure 1 same), the top plate 1 on the upper surface and the top plate 8 on the lower surface are circular with a radius of 15 cm and a thickness of 10 mm. The size of the encapsulation layer 2 is a cylinder with a base radius of 15 cm, a height of 8 cm and filled with asphalt sand. Fifteen piezoelectric ceramic column units 3 are densely arranged between the upper surface top plate 1 and the lower surface top plate 8, wherein the piezoelectric ceramic column unit 3 is formed by stacking four piezoelectric ceramic column bodies 4, and the piezoelectric ceramic column units 3 and A metal sheet 5 is directly provided on the surface top plate, and a metal sheet 5 is provided between each piezoelectric ceramic column body 4 . The pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com