Computer simulation testing system for high voltage direct current transmission equipment

A technology of high-voltage direct current transmission and computer simulation, which is applied in the field of test systems, can solve problems such as the inability to reflect the action of the thyristor level, the inability to effectively simulate the fault on the valve side of a single valve failure, and the inability to accurately reflect the action response of the TTM board, etc., to ensure realism effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

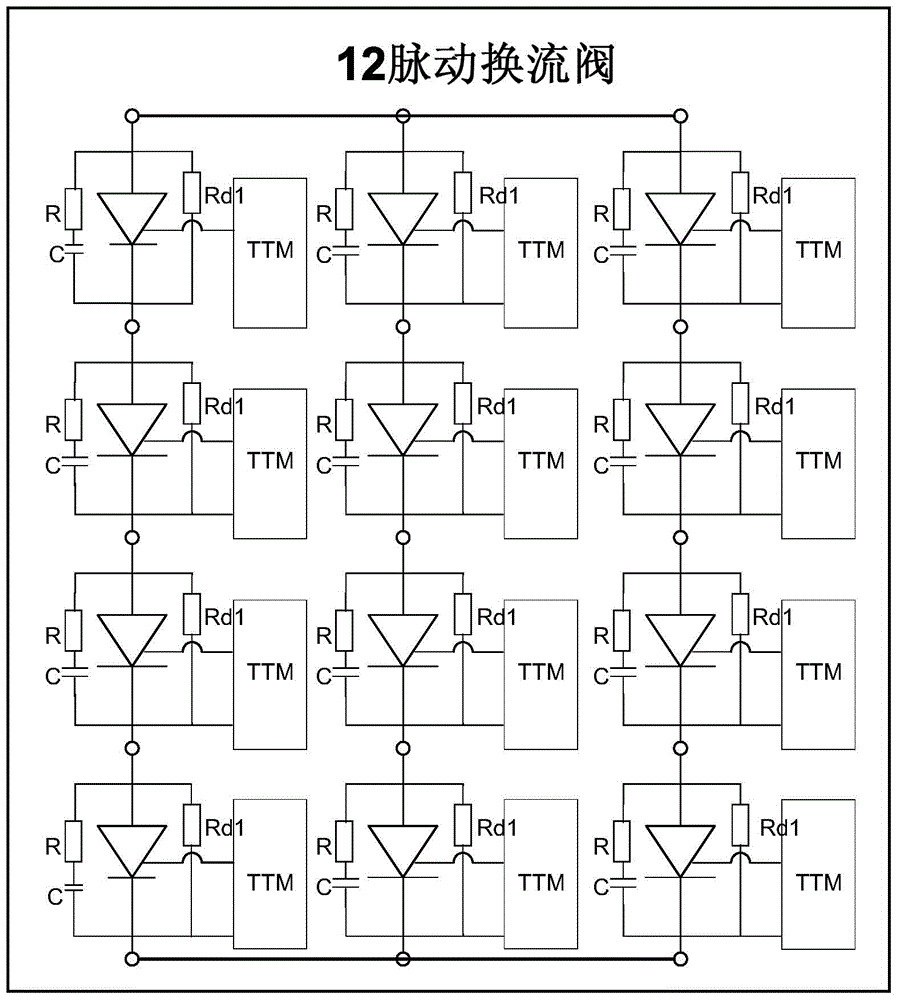

[0032] The invention provides a new type of computer simulation test device for HVDC transmission equipment, which is designed to meet the VBE and TTM of HVDC transmission equipment for RTDS (real-time digital simulation) test, and its main function is to simulate the actual high voltage Triggering and monitoring systems for HVDC converter valves and operating status of thyristor stages. Due to the large volume of the converter valve tower of the main HVDC power transmission main equipment, the 12-pulse converter valve tower involves a lot of thyristor stages, the actual physical size is tens of meters high, and the operating voltage is as high as hundreds of kilovolts. The equipment investment is extremely high, only The test verification can only be carried out after the converter station is built. The test device of the present invention uses RTDS to simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com