Perovskite-type battery based on carbon counter electrode and preparation method thereof

A perovskite type, battery technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as high cost, and achieve the effect of reasonable structure, simple preparation method, large commercial development and large-scale production value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

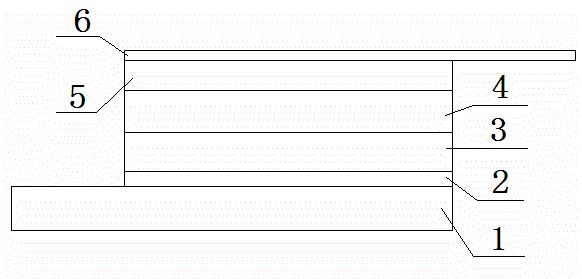

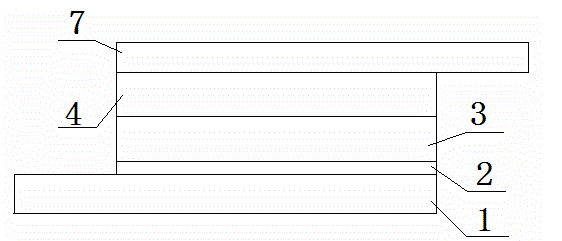

[0028] This embodiment discloses a perovskite battery based on a carbon counter electrode, such as figure 1 Shown:

[0029] Perovskite cells consist of parallel, sequentially connected FTO conductive glass substrates1, 80 nm TiO 2 Dense layer 2, 400 nm semiconductor TiO 2 Nanoporous film 3, perovskite light absorber film 4 with a thickness of 1-4 μm (CH 3 NH 3 PbICl 2 )) and a 10 μm conductive carbon film 7;

[0030] The preparation method of the perovskite battery based on the carbon counter electrode specifically comprises the following steps:

[0031]Step 1: Spin-coat a layer of titanate solution on the cleaned FTO conductive glass substrate, and sinter at 500 °C for 40 min to obtain TiO 2 dense layer with a measured thickness of 80 nm.

[0032] Step 2: On TiO 2 On the dense layer, a layer of nano-TiO was screen-printed 2 The slurry was dried at 120 °C and then sintered at 500 °C for 40 min to obtain TiO 2 Nanoporous film with a measured thickness of 400 nm.

[0...

Embodiment 2

[0037] This embodiment discloses a solar cell: a perovskite cell based on carbon counter electrodes, including parallel and sequentially connected FTO conductive glass substrates, 50 nm TiO 2 Dense layer, 600 nm semiconductor Al 2 o 3 Nanoporous film, perovskite light absorber film (CH 3 NH 3 PB 3 ) and a 5 μm conductive carbon film.

[0038] The preparation method of the perovskite battery based on the carbon counter electrode specifically comprises the following steps:

[0039] Step 1: On the cleaned FTO conductive glass substrate, cover the surface with a layer of titanate solution by dipping-pulling method, and sinter at 550 °C for 30 min to obtain TiO 2 dense layer with a measured thickness of 50 nm.

[0040] Step 2: On TiO 2 On the dense layer, spin-coat a layer of nano-Al 2 o 3 The slurry was dried at 100 °C and then sintered at 480 °C for 40 min to obtain Al 2 o 3 Nanoporous film with a measured thickness of 600 nm.

[0041] Step 3: methyl iodide (CH 3 NH ...

Embodiment 3

[0047] This embodiment discloses a solar cell: a perovskite cell based on a carbon counter electrode, comprising

[0048] Parallel, sequentially connected FTO conductive glass substrate, 80 nm TiO 2 Dense layer, 500 nm semiconductor TiO 2 Nanoporous film, perovskite light absorber film (CH 3 NH 3 PbCl 3 ) and a 15 μm conductive carbon film.

[0049] The preparation method of the perovskite battery based on the carbon counter electrode specifically comprises the following steps:

[0050] Step 1: On the cleaned FTO conductive glass substrate, a layer of TiO was prepared by spray pyrolysis at 500 °C 2 dense layer with a measured thickness of 80 nm.

[0051] Step 2: On TiO 2 On the dense layer, a layer of nano-TiO was screen-printed 2 The slurry was dried at 100 °C and then sintered at 500 °C for 30 min to obtain TiO 2 Nanoporous film with a measured thickness of 500 nm.

[0052] Step 3: PbCl 2 dissolved in tert-butanol solvent and spin-coated onto TiO 2 on nanoporous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com