Method for testing intelligent components of power transformer on site

A technology for power transformers and field testing, applied in the measurement of electrical variables, instruments, and electrical measurement, can solve problems such as incompleteness and insufficient primary equipment maintenance, and achieve the effect of improving work effects, sufficient maintenance, and improving processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

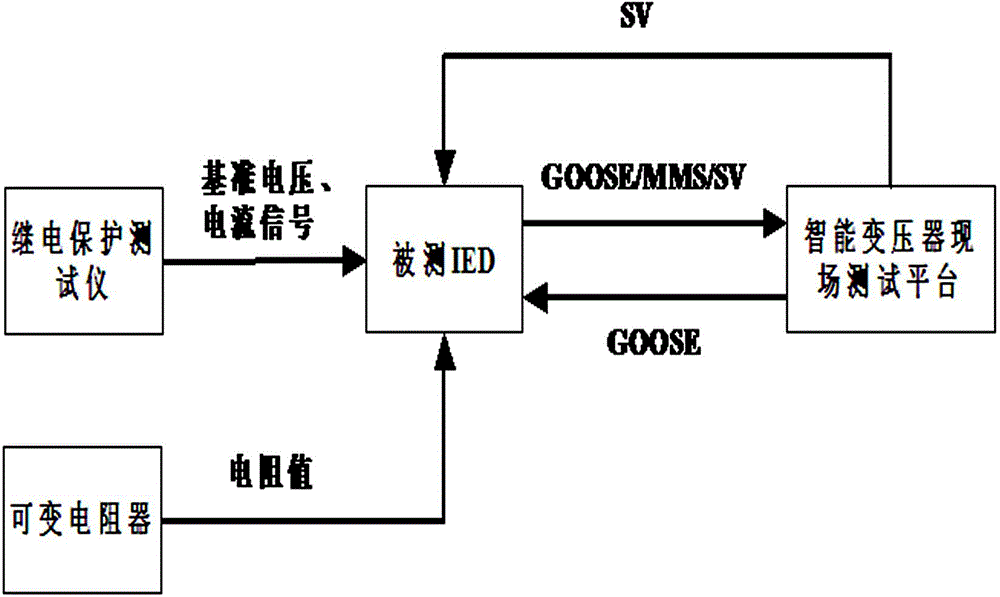

[0057] Such as figure 1 As shown, a method for on-site testing of intelligent components of a power transformer is a single unit, that is, without monitoring the main IED, and the on-site testing equipment includes: a relay protection tester, a variable resistor, an on-site testing platform for an intelligent transformer, and the IED to be tested. The relay protection tester and the variable resistor are respectively connected to the tested IED with cables; the intelligent transformer on-site test platform is connected with the tested IED with optical fibers. Taking the measured IED as an example, the test steps are:

[0058] 1) The tester selects all the functions of the transformer to measure the IED on the intelligent transformer field test platform, reads the relevant configuration files, and generates a test plan.

[0059] 2) Use the relay protection tester as the current signal standard source to generate a 4-20mA DC current signal, simulate the oil level and oil pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com