Surface acoustic wave electric current sensor

A technology of current sensor and surface acoustic wave, which is applied in the direction of measuring current/voltage, instruments, and measuring electrical variables, etc. It can solve the problems of large energy loss of reflectors, low signal-to-noise ratio of reflected signals, and huge influence on the stability of current sensors. Achieve good temperature stability and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

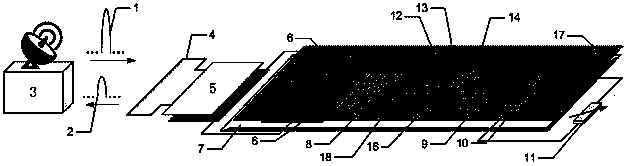

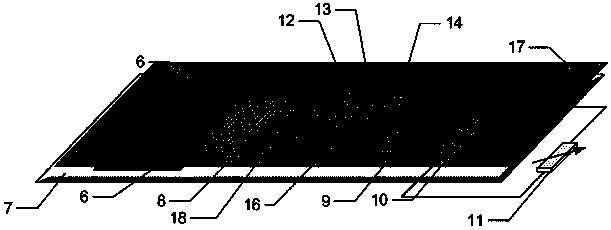

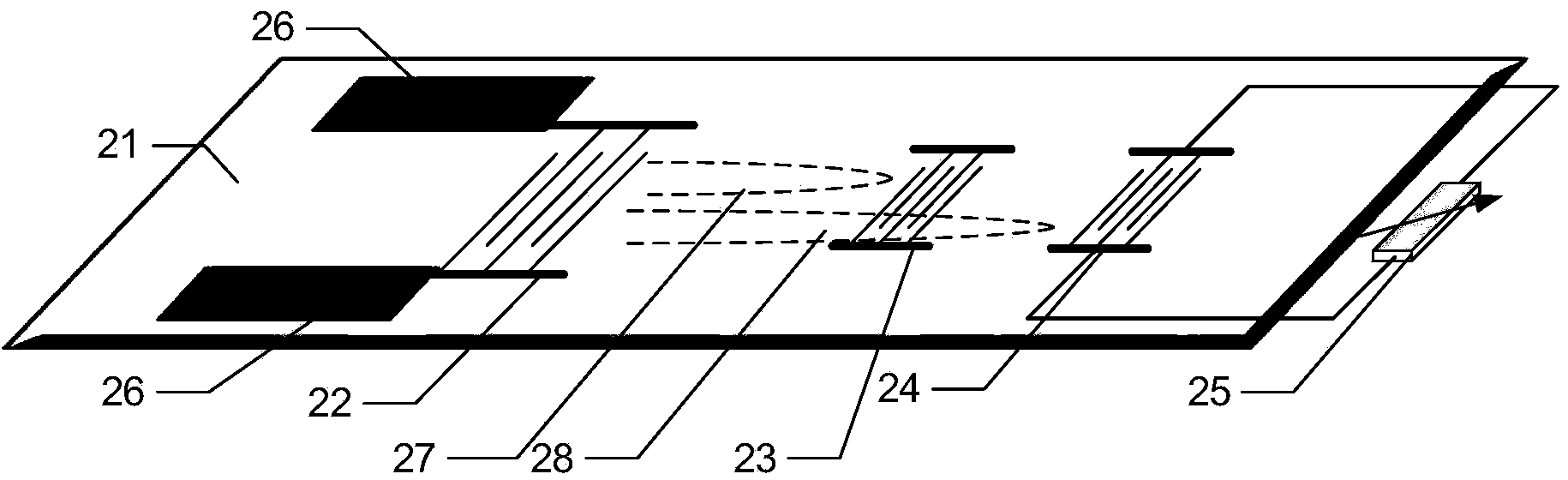

[0045] Figure 2a A schematic diagram of the composition of the SAW current sensor provided by the embodiment of the present invention, such as Figure 2a As shown, the SAW current sensor includes: a first electromagnetic wave signal 1, a second electromagnetic wave signal 2, a reading unit 3, a wireless antenna 4, an impedance matching network 5, a conductive film 6, a piezoelectric substrate 7, EWC / SPUDT8, the second One-way reflector (comprising: first interdigital reflector 9 and second interdigital reflector 10), magnetoresistor 11, second-way reflector (comprising: first short-circuit grid reflector 12, second short-circuit grid reflector 13 and the third short grid reflector 14), the first sound-absorbing glue 15, the second sound-absorbing glue 15', the echo signal 16 of the first road reflector, thin film 17,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electron mobility | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com