Calibration device and method of mass spectrum detector

A mass spectrometer detector and a calibration device technology, applied in the field of calibration devices, can solve problems affecting sampling accuracy and stability, changes in permeable membrane stability, etc., and achieve the effects of improving sampling accuracy, shortening sampling time, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

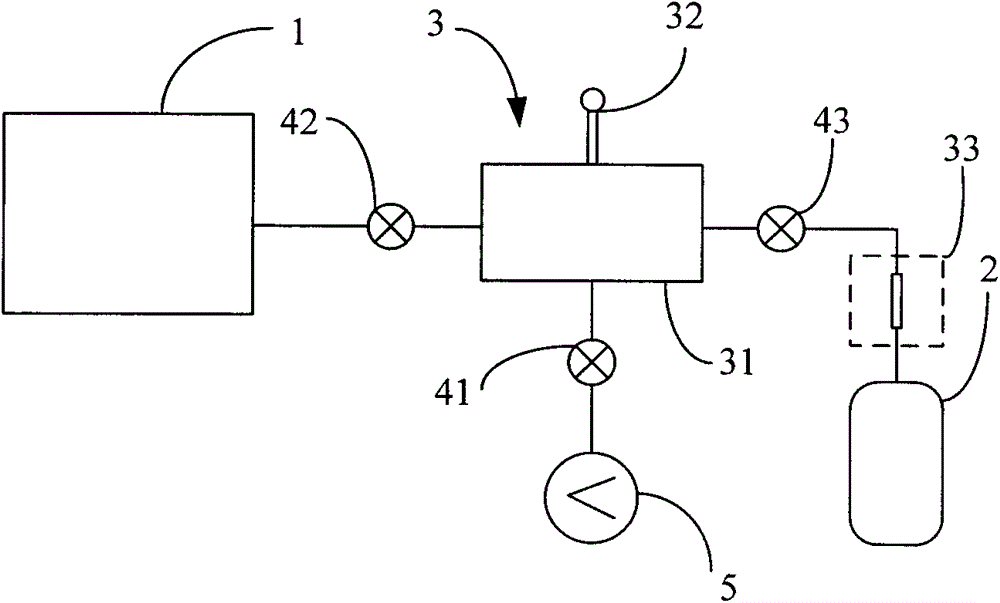

[0042] see figure 1 , a mass spectrometry detector calibration device, including a mass spectrometer detector 1, a standard gas, a sampling unit 3, a switching unit, a controller unit (not shown in the figure) and a pump 5.

[0043] The standard gas is provided by the standard gas cylinder 2; the standard gas can be: halogenated hydrocarbons, benzene series, p-bromofluorobenzene and other volatile organic compounds.

[0044] The sampling unit 3 includes a sampling chamber 31, a heating module (not shown in the figure) and a pressure measurement module 32; the sampling chamber 31 is connected to the pump 5, the mass spectrometer 1, and the calibration gas cylinder 2 respectively through a switching unit The heating module is arranged outside the sampling chamber 31; the pressure measurement module 32 is arranged on the sampling chamber 31 to monitor the pressure of the sampling chamber 31 in real time;

[0045] Preferably, the pressure measurement module 32 is a vacuum gauge. ...

Embodiment 2

[0070] This embodiment provides a calibration device for a mass spectrometer detector, which is an application example of embodiment 1 when calibrating a mass spectrometer detector.

[0071] see figure 1 , the mass spectrometer calibration device of this application example includes a mass spectrometer 1, a standard gas, a sampling unit 3, a switching unit, a controller unit (not shown in the figure) and a pump 5.

[0072] The standard gas is provided by the standard gas bottle 2; the standard gas is: halogenated hydrocarbon.

[0073] The sampling unit 3 includes a sampling chamber 31 , a heating module (not shown in the figure), a pressure measurement module 32 and a damping regulator 33 , and the pressure measurement module 32 is a vacuum gauge.

[0074] The switching unit includes a valve 41 , a valve 42 and a valve 43 .

[0075] The controller unit is connected with the heating unit, the pressure measurement module 32 , the switching unit and the pump 5 .

[0076] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com