Mine soft rock grouting test piece indoor simulation manufacturing method and manufacturing device

A control device and test piece technology, applied in the field of geotechnical engineering, can solve problems such as the difficulty of simulating the grouting environment, the inability to consider the influence of confining pressure, and the inability to accurately determine the grouting parameters, etc., and achieve the effect of wide application range and uniform and reliable grout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

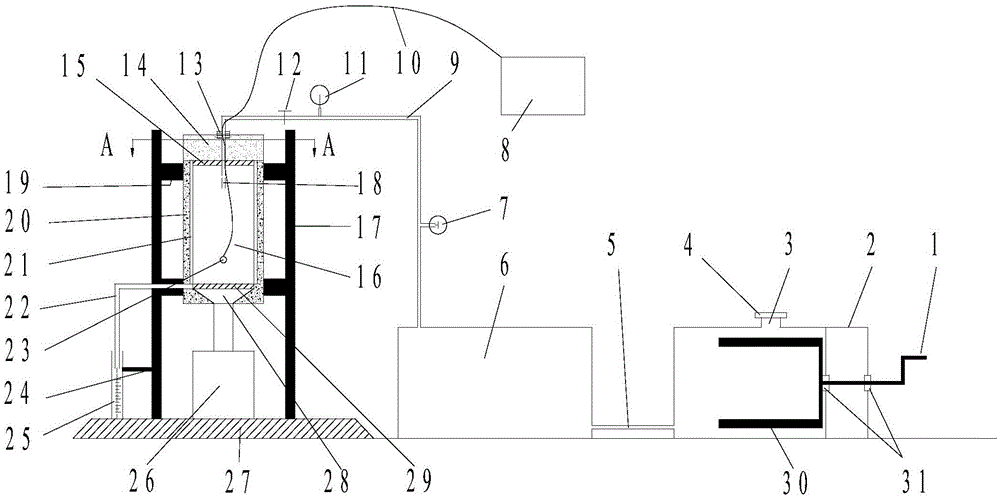

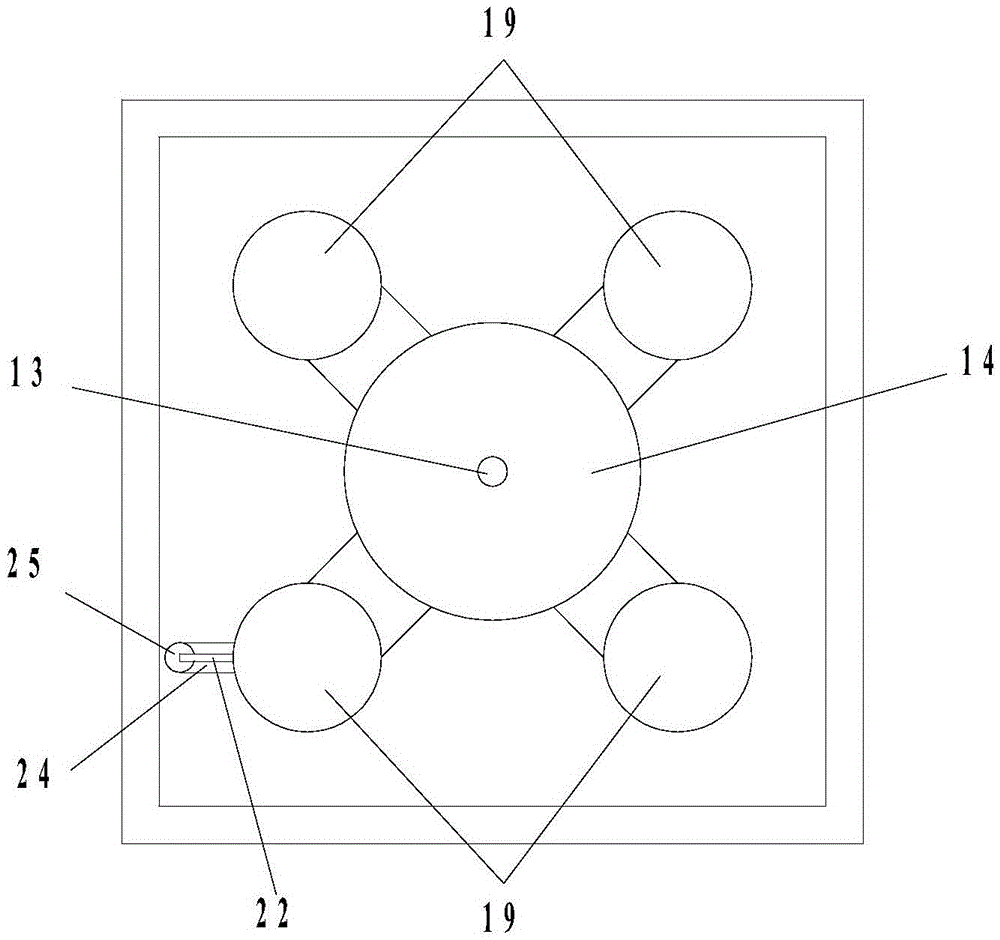

[0041] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0042] Such as figure 1 and figure 2 Shown is the operating state diagram of the mine soft rock grouting test piece indoor simulation production device of the present invention, as can be seen from the figure: it is composed of a test piece loading system, a slurry mixing system, a grouting system and a monitoring system;

[0043] Described specimen loading system comprises the test frame that is formed by welding base 27 and four upright columns 17, is provided with vertical loading oil cylinder 20 on the test frame, and loading oil cylinder 20 is installed on the test frame by loading oil cylinder bracket 19, and test frame The base 27 of the base is provided with a hydraulic jack 26, and the loading cylinder and the hydraulic jack 26 are on the same axis; the bottom of the loading cylinder 20 is provided with a rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com