Production process and curing drying equipment for solar polycrystalline silicon quartz crucible

A technology of quartz crucible and production process, which is applied in the production process of solar polysilicon quartz crucible and its maintenance and drying equipment, can solve the problems of difficult heating, uniform dehumidification, and affecting the quality of firing kiln products, so as to ensure that the product is intact, Prevent bursting, the effect of reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the present invention, an organic monomer is added to the quartz ceramic slurry, which is formed in a non-porous mold and then solidified directly to obtain a crucible product, which is fired by thermal equipment. The entire quartz crucible injection molding process is: high-purity melting Quartz raw material (adding organic monomers) → preparation of quartz ceramic slurry → injection molding → curing and drying → firing → testing → packaging → finished product → storage.

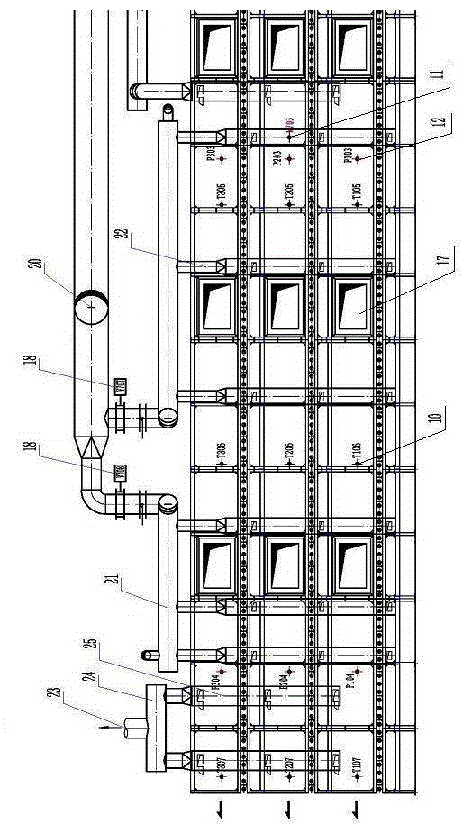

[0037] Maintenance and drying equipment Take the construction of a three-layer continuous maintenance roller kiln with a kiln length of 36m as an example. The whole kiln is equipped with a three-layer structure, with a total of 16 sections before and after. , Section 16 is the cooling section. On both sides of the kiln wall 28 of each roller kiln, there are temperature measuring holes 10, humidity measuring holes 11, pressure measuring holes 12, hot air regulating holes 27 and observation doors 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com