Tunnel portal breaking method by using shield tunneling machine on quicksand strata

A technology of shield machine and tunnel door, which is used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of risk in the removal of tunnel doors in quicksand formations, and achieve the effect of reducing risks and ensuring safe reception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The enclosure structure of Duantou well adopts the form of underground continuous wall, the wall thickness is 800mm, and there are two layers of steel bars inside and outside.

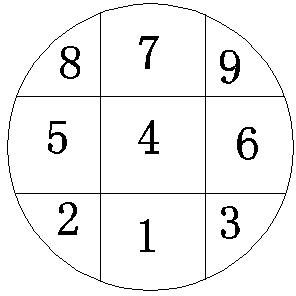

[0023] The hole door is demolished twice manually.

[0024] ① Break the outer protective layer for the first time, and break it in order from bottom to top, that is, start to break the concrete on the surface from the bottom of the hole, the thickness is 50mm, and the remaining 750mm concrete can be broken after the outer row of steel bars are cut off;

[0025] ② A circular opening with a diameter of 1500mm is chiseled at the center of the door;

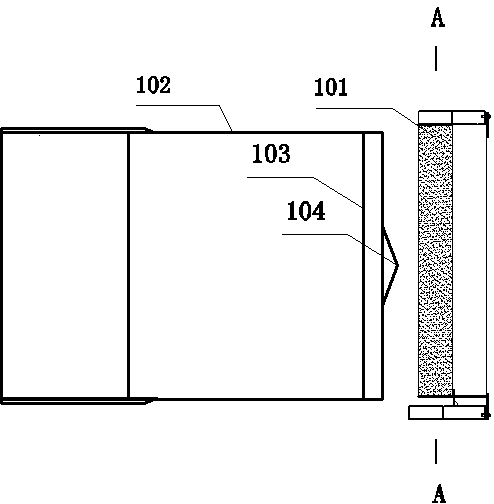

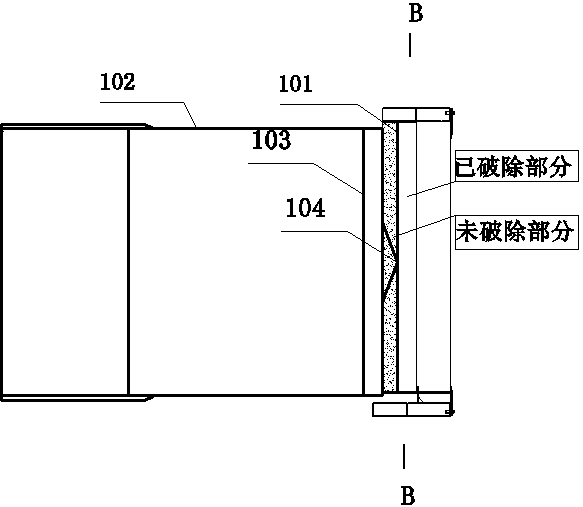

[0026] ③ The shield machine 102 starts to advance, the cutter head 103 leans against the ground wall, and the knife tip 104 is exposed;

[0027] ④ Destroy the remaining walls and cut off the steel bars;

[0028] ⑤ The shield machine 102 is jacked forward until the shield tail is completely put on the shield and the tail of the shield comes out of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com