Prunus humilis and blueberry wine and preparation method thereof

A technology of blueberry and blueberry, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of low pigment content and lower product quality, and achieve the effects of improving sensory and nutritional quality, improving product quality, and improving appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

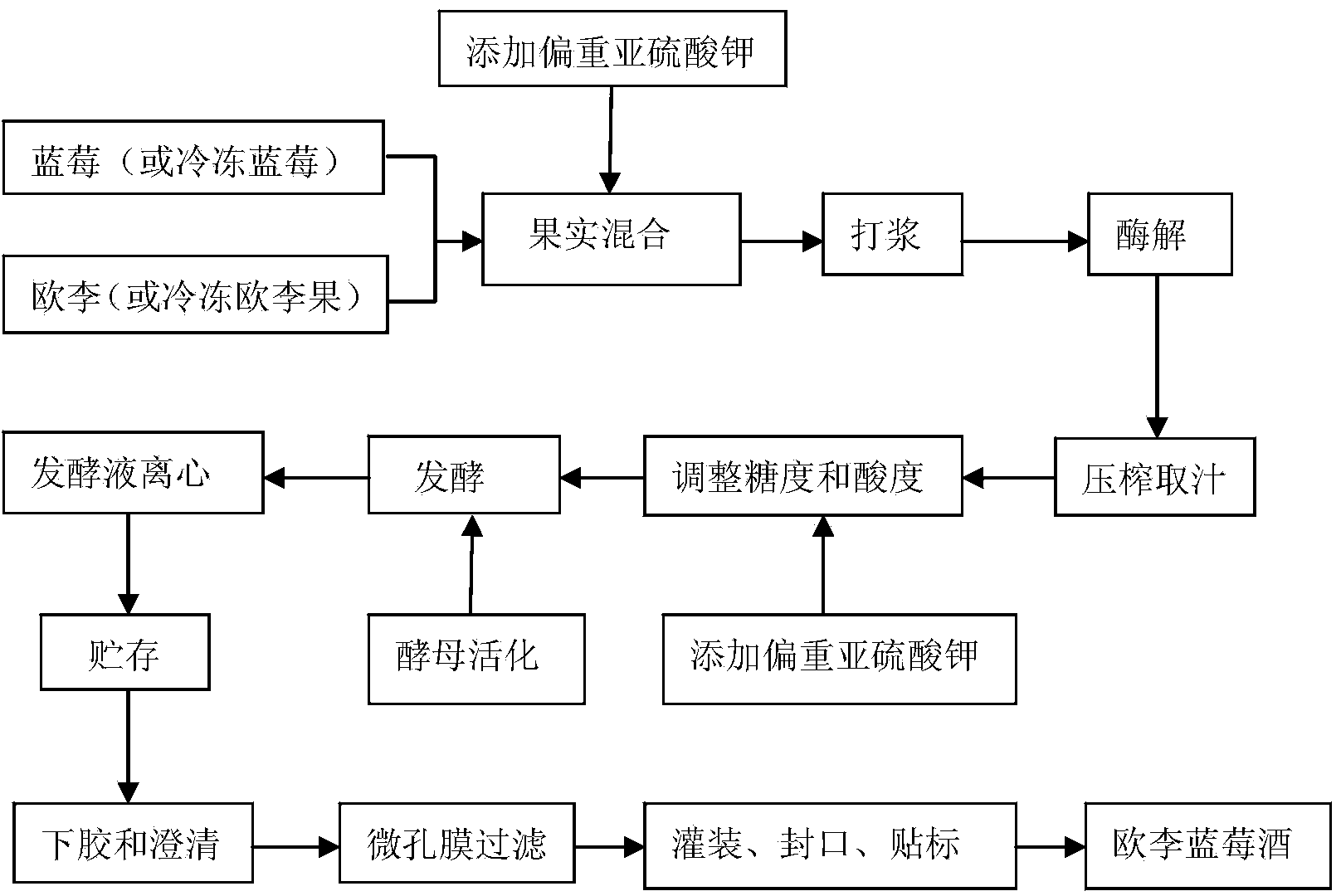

Method used

Image

Examples

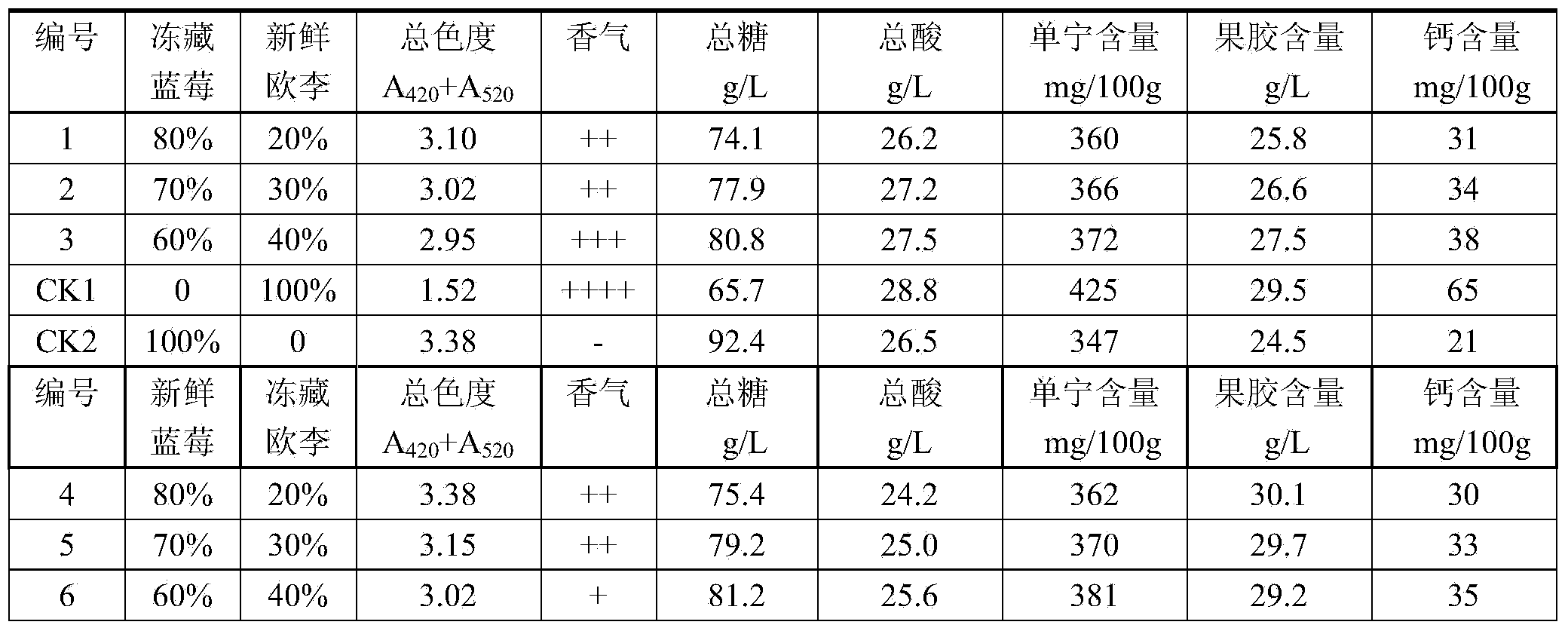

Embodiment 1

[0039](1) Freeze the blueberries that have been screened and removed, and store them until the season of Oli harvest. (2) 20kg of fresh prunes were pitted, mixed with 80kg of thawed blueberry fruit, no deionized water was added, and potassium metabisulfite was added at a ratio of 0.1g / kg, stirred evenly for 2 hours, and then crushed and beaten. (3) Add pectinase for enzymolysis, the amount of enzyme added is 0.1% of the fruit weight, the enzymolysis temperature is 40°C, and the treatment time is 0.5h. (4) Squeeze the enzymatic hydrolyzate to extract the juice, and filter it. (5) Add white granulated sugar to the filtered fruit juice to increase the sugar content to 12%, adjust the pH to 3.0 with citric acid, after the adjustment is completed, add potassium metabisulfite at a ratio of 0.05g / kg. (6) Yeast solution was added after 4 hours of blending treatment for closed fermentation, and activated yeast was added in an amount of 0.1 g / L. The fermentation temperature was contro...

Embodiment 2

[0041] (1) Freeze the blueberries that have been screened and removed, and store them until the season of Oli harvest. (2) Remove the pits from 30kg of fresh prunes, mix them with 70kg of thawed blueberry fruits, add 1 / 2 of the fruit weight in deionized water, and add potassium metabisulfite at a ratio of 0.01g / kg, stir evenly for 2 hours, then proceed Crushing and beating. (3) Add pectinase for enzymolysis, the amount of enzyme added is 0.2% of the fruit weight, the enzymolysis temperature is 50° C., and the treatment time is 1 h. (4) Squeeze the enzymatic hydrolyzate to extract the juice, and filter it. (5) Add white granulated sugar to the filtered fruit juice to increase the sugar content to 15%, and adjust the pH to 3.3 with citric acid. After the adjustment is completed, add potassium metabisulfite in a ratio of 0.1g / kg. (6) Yeast solution was added after 4 hours of blending treatment for closed fermentation, and activated yeast was added in an amount of 0.8 g / L. The ...

Embodiment 3

[0043] (1) Freeze the blueberries that have been screened and removed, and store them until the season of Oli harvest. (2) Remove the core of 40kg of fresh prunes, mix with 60kg of thawed blueberry fruit, add 1 / 2 fruit weight deionized water, and add potassium metabisulfite at a ratio of 0.3g / kg at the same time, stir evenly for 2 hours before proceeding Crushing and beating. (3) Add pectinase for enzymolysis, the amount of enzyme added is 0.3% of the fruit weight, the enzymolysis temperature is 60° C., and the treatment time is 2 hours. (4) Squeeze the enzymatic hydrolyzate to extract the juice, and filter it. (5) Add white granulated sugar to the filtered fruit juice to increase the sugar content to 18%, adjust the pH to 3.2 with citric acid, after the adjustment is completed, add potassium metabisulfite in a ratio of 0.01g / kg. (6) Yeast solution was added after 4 hours of blending treatment for closed fermentation, and activated yeast was added in an amount of 1 g / L. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com