A dimethoxymethane gasoline based on various non-national standard gasoline components

A dimethoxymethane, non-national standard technology, applied in the field of dimethoxymethane gasoline, can solve the problems of transportation, storage, use difficulties, not widely used, low-temperature stratification, etc., and achieve resistance to separation when encountering water High resistance to low temperature separation, improved cost performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

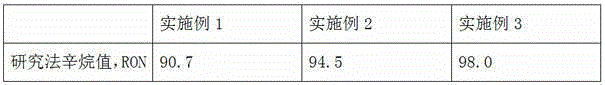

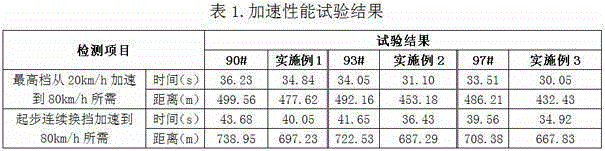

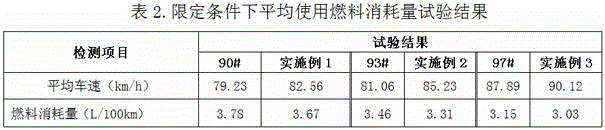

Embodiment 1

[0033] 1. Preparation of functional additives: under normal temperature and pressure, take 5 kg of polyisobutenyl succinimide, 3 kg of fatty acid, and 0.5 kg of cerium dioxide and add them into the tank and stir to mix evenly;

[0034] 2. Preparation of mixed solution: under normal temperature and pressure, add 88 kg of dimethoxymethane (DMM) and 5 kg of tert-amyl methyl ether (TAME) into the tank and mix naturally to obtain a mixed solution;

[0035] 3. Preparation of blended fuel: add 2kg of functional additives to the mixed solution, fully stir and mix evenly;

[0036] 4. Preparation of dimethoxymethane gasoline: Take 10kg of blended fuel, 70kg of naphtha, and 20kg of aromatized gasoline components and mix them in the tank.

Embodiment 2

[0038] 1. Preparation of functional additives: under normal temperature and pressure, take 6.5 kg of polyisobutenyl succinimide, 4 kg of fatty acid, and 1 kg of cerium oxide and add them into the tank, stir and mix evenly;

[0039] 2. Preparation of mixed solution: under normal temperature and pressure, add 95 kg of dimethoxymethane (DMM) and 8 kg of tert-amyl methyl ether (TAME) into the tank and mix naturally to obtain a mixed solution;

[0040] 3. Preparation of blended fuel: add 5kg of functional additives to the mixed solution, stir well and mix evenly;

[0041] 4. Preparation of dimethoxymethane gasoline: Take 20kg of blended fuel, 70kg of naphtha, and 10kg of isomerized gasoline components and mix them in the tank.

Embodiment 3

[0043]1. Preparation of functional additives: under normal temperature and pressure, take 5.5kg of polyisobutenyl succinimide, 3.5kg of fatty acid, and 1kg of cerium dioxide into the tank and stir to mix evenly;

[0044] 2. Preparation of mixed solution: under normal temperature and pressure, add 90 kg of dimethoxymethane (DMM) and 5 kg of tert-amyl methyl ether (TAME) into the tank and mix naturally to obtain a mixed solution;

[0045] 3. Preparation of blended fuel: add 5kg of functional additives to the mixed solution, stir well and mix evenly;

[0046] 4. Preparation of dimethoxymethane gasoline: Take 30kg of blended fuel, 40kg of naphtha, and 30kg of aromatized gasoline components and mix them in the tank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com