Preparation and application of a fixed bioactive filler

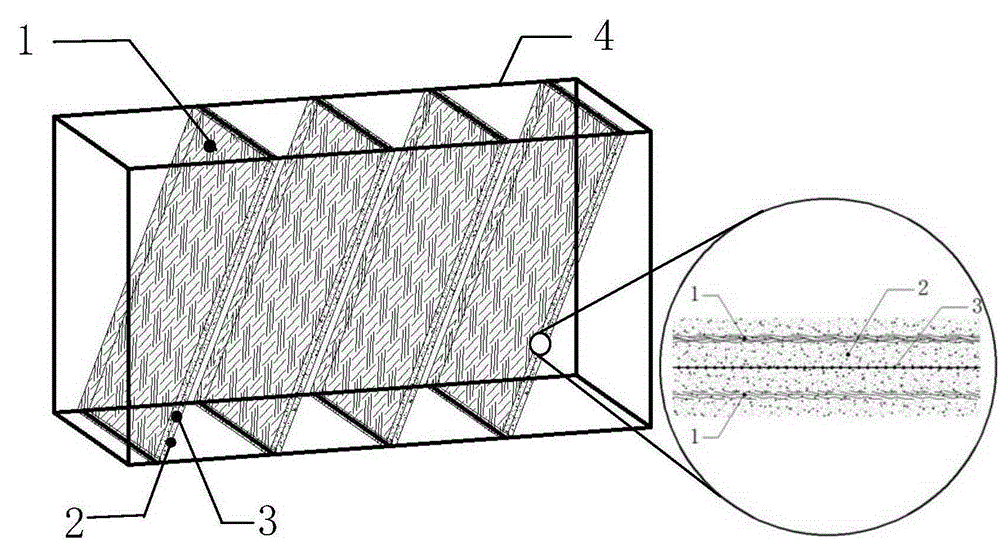

A biologically active and fixed technology, applied in the field of water treatment, can solve the problems of unsatisfactory effect of biologically active fillers, poor stability of biologically active fillers, easy falling off of embedded bodies, etc., and achieve good substrate mass transfer effect, acid and alkali resistance The effect of strong ability and strong resistance to water impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now, the present invention will be further described by taking nitrifying bacteria as an example. This embodiment is intended to further illustrate the preparation and application of fixed bioactive fillers, but the embodiment of the present invention is not limited thereto.

[0025] (1) The domesticated nitrifying bacteria suspension was concentrated to 7.5x10 after centrifugation and dehydration 8 pc / mL to obtain the concentrated solution of bacteria, take 14.0L concentrated solution of nitrifying bacteria for subsequent use;

[0026] (2) Take 10.0kg of polyvinyl alcohol in a water bath and heat it to 90°C and dissolve it in 70L of water to obtain a polyvinyl alcohol solution;

[0027] (3) Cool the polyvinyl alcohol solution in step (2) to 30°C and fully mix it with the concentrated solution of nitrifying bacteria obtained in step (1). Alcohol mass concentration is 100g / L;

[0028] (4) Four layers of polyvinyl alcohol non-woven fabric and one layer of textile fabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com