Foldable type hydraulic hoisting frame

A hydraulic lifting and folding technology, which is applied in the direction of lifting frames and lifting devices, can solve the problems of no fundamental improvement in overall rigidity and stability, high space utilization, and high overall rigidity of equipment, so as to achieve full utilization of the crank arm length and layout Small footprint and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] 1. According to different usage requirements, the lifting frame can be designed into the following types:

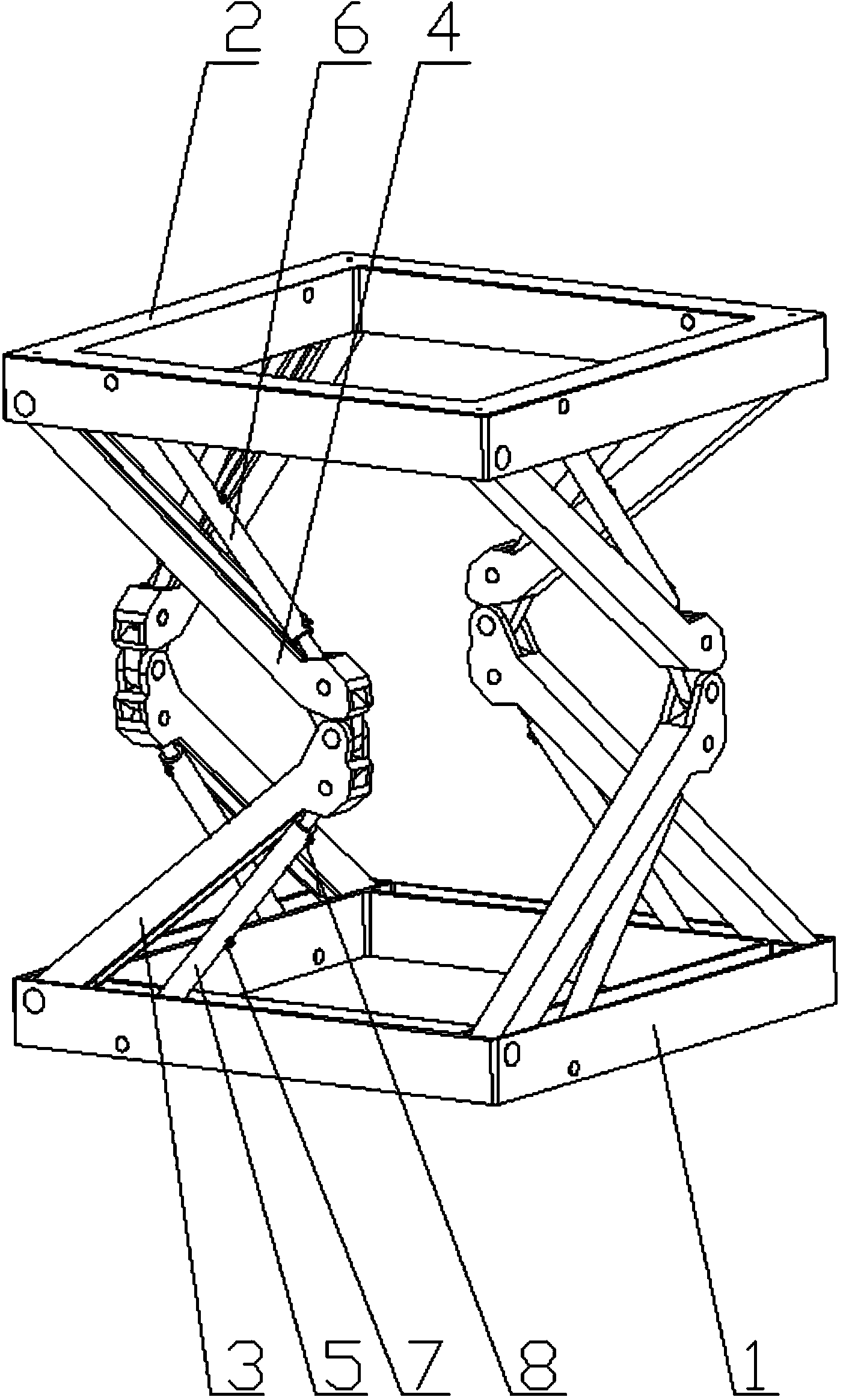

[0044] 1. Crank arm side bending lifting frame, such as figure 1 shown. Its characteristics are:

[0045] Use three or more sets of lifting crank arms, the bending direction of the crank arms is the same counterclockwise direction or the same clockwise direction or a lateral staggered direction, the end of the piston rod of the upper lifting hydraulic cylinder 6 is hinged to the lower part of the upper crank arm 4 , the end of the piston rod of the lower lift hydraulic cylinder 5 is hinged with the upper part of the lower crank arm 3 .

[0046] 2. The curved arm is opposite to the radial bending lifting frame, such as Figure 5 shown. Its characteristics are:

[0047] Three or more pairs of lifting crank arms are used, and the bending direction of the crank arms is opposite radial. The crank arm 3 top is hinged.

[0048] 3. Parallel-to-bending lifting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com