A variable width copper foil transfer device

A transfer device and width technology, applied in the field of copper foil, can solve the problems of easy safety accidents, unsafe hidden dangers, low work efficiency, etc., and achieve the effect of saving manpower, lifting balance and stability, and not easy to tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

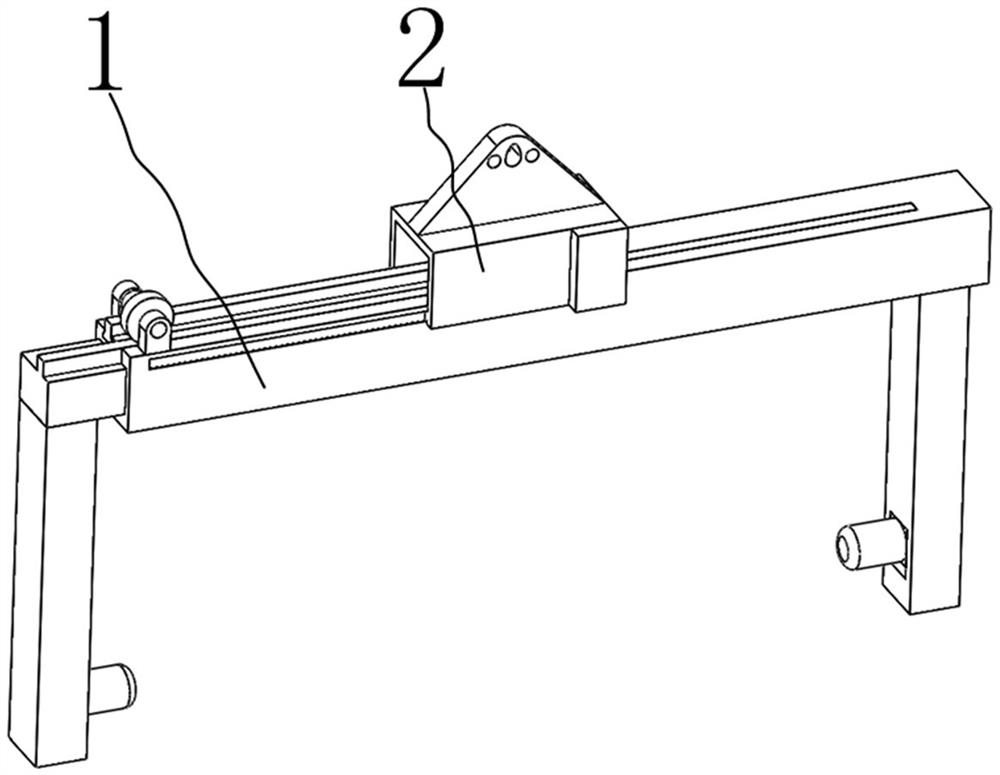

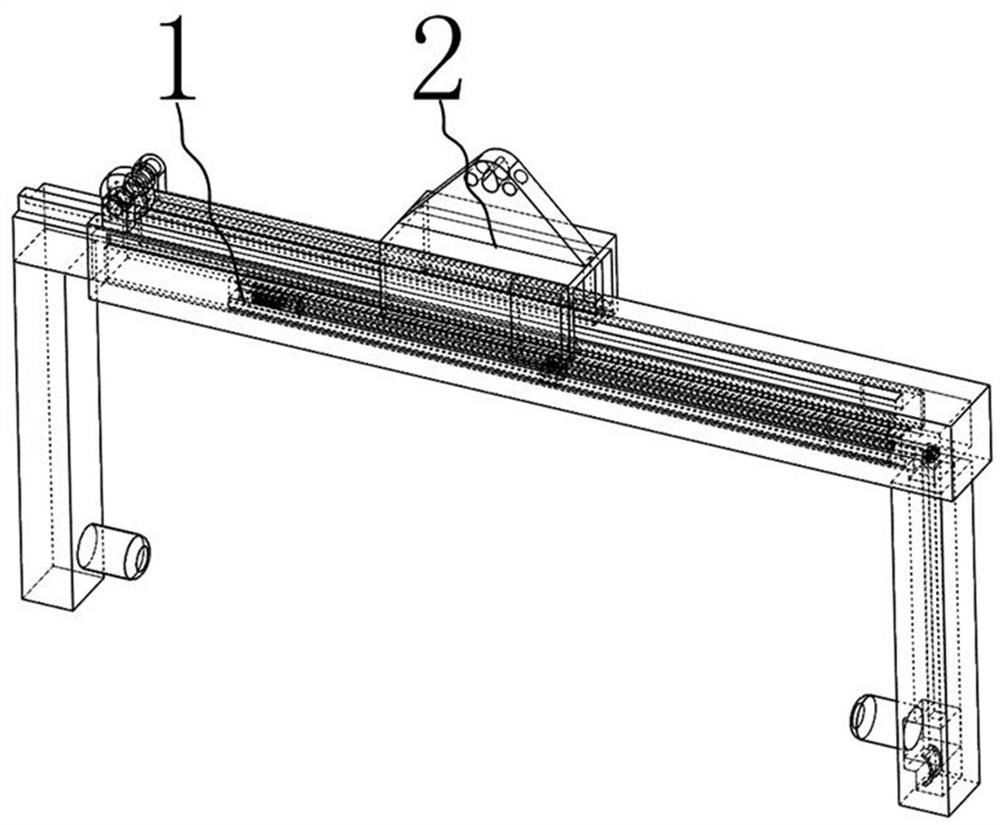

[0049] Copper foil transfer devices such as figure 1 , 2 As shown, it includes a hoisting mechanism 1 and a hitch 2, among which image 3 As shown, the hitch device 2 used to connect the driving hook is installed on the upper side of the hoisting mechanism 1, and as Figure 4 As shown, the hitch 2 is always located in the middle position on the upper side of the hoisting mechanism 1 .

[0050] Such as Figure 10 , 11 As shown, the above-mentioned hoisting mechanism 1 includes a hoisting overcoat mechanism 3 and a hoisting inner rod mechanism 4, wherein as Figure 15 , 16 As shown, the hoisting overcoat mechanism 3 is made up of telescopic overcoat 24, the second vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com