Transformer collector

A technology for collecting parts and transformers, which is applied in the direction of containers, rigid containers, internal accessories, etc., can solve the problems of difficult to meet the storage and transportation requirements of transformers, unreasonable structural design, and miscellaneous classified transportation parts, etc., to save packaging materials and structure Compact, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing of description, the present invention will be further described.

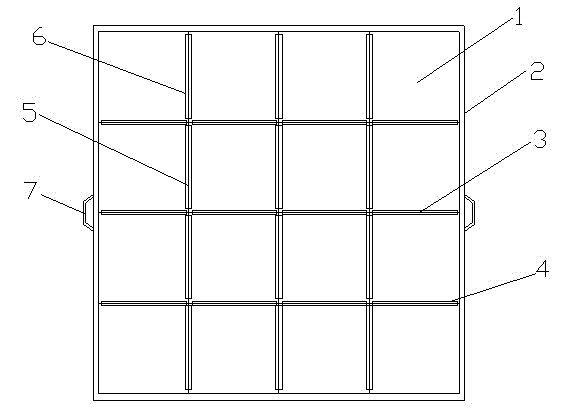

[0020] Such as figure 1 As shown, a transformer collector includes a chassis 1 and a side plate 2 surrounding the chassis. The height of the side plate 2 is higher than the plane of the chassis 1. In the figure, the chassis 1 is a square; The chassis plane is inserted into the first-class slot 4 of the warp divider 3, and the second-class slot 6 for inserting the weft divider 5 perpendicular to the chassis plane is provided in the weft direction of the chassis 1.

[0021] The chassis 1 and the side plate 2 are all made of PET material, the warp separator 3 and the weft separator 5 are all made of EPE pearl cotton; the side plate 2 is provided with a handle 7, which can be easily taken by the handle 7 The whole chassis1.

[0022] The width of the warp separator 3 is smaller than the distance between adjacent weft threads, and the width of the weft separator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com