A winding device for processing aircraft girder belts with composite materials

A technology of composite materials and girder belts, which is applied in the field of aircraft manufacturing, can solve problems such as uneven winding thickness, waste and restrictions of prepreg tapes, and achieve stable product quality, avoid stress concentration, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

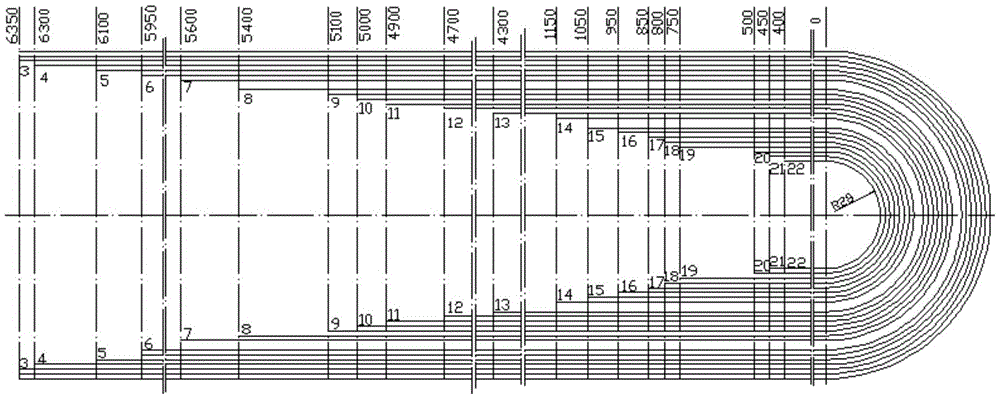

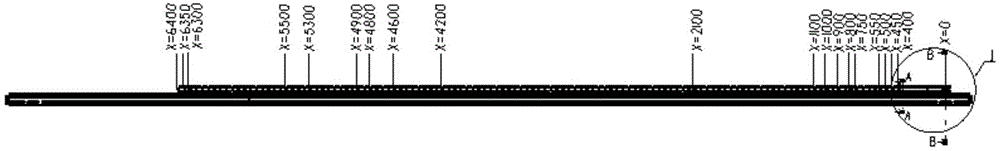

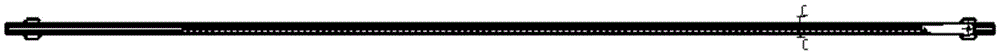

[0020] The present invention will be described in further detail below. The winding device includes a winding frame 1, a slider assembly 2, and a winding assembly 3. The winding frame 1 is composed of a winding guide 101, a handle 102, a screw 103, a nut 104, and a baffle 105. The winding guide is fixed on the bracket of the winding machine, the handle is fixed on the side of the winding guide, and the baffle is fixed on the end faces of both ends of the winding guide. , The slider assembly 2 is made into several groups of modular components according to the requirements of the cut drawing of each layer of the aircraft girder belt. The slider assembly 2 is composed of a sliding cover 201, a sliding block 202, a guide post 203, and a screw 204. The sliding cover On the sliding block and connected with the sliding block through a clearance fit, the sliding cover is made of nylon, the guide post is fixed under the sliding block and connected with the winding guide on the winding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com