Device and method for solidifying superhard-material grinding wheel abrasive block with substrate

A superhard material, grinding wheel grinding technology, applied in grinding devices, grinding/polishing equipment, metal processing equipment, etc., can solve the large bonding stress between the abrasive block and the substrate, low production efficiency, and difficulty in ensuring uniformity. and other problems, to achieve the effect of ensuring the consistency of curing strength, improving bonding efficiency and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

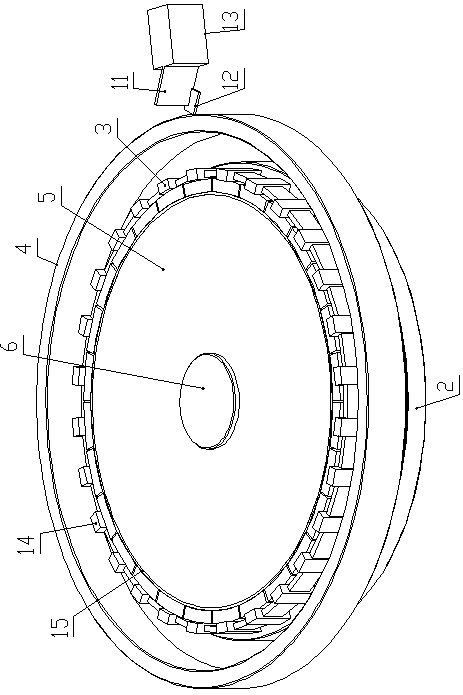

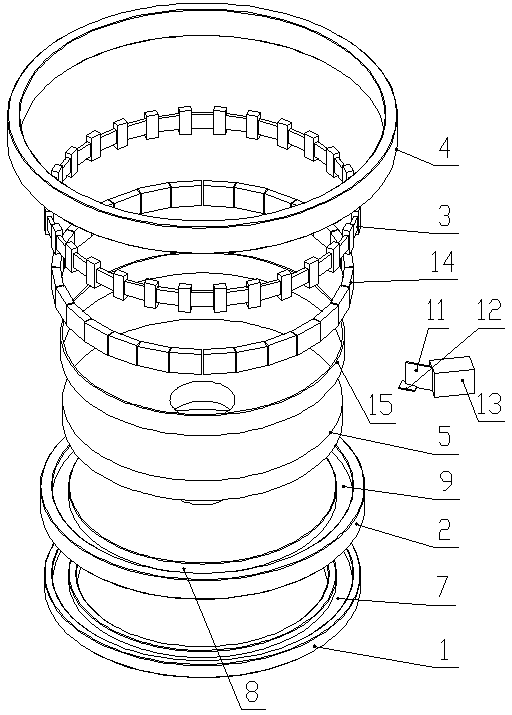

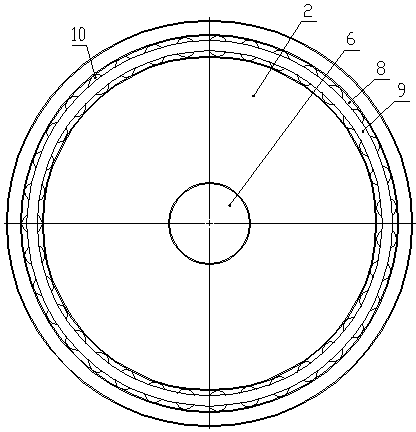

[0041] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a superhard material grinding wheel abrasive block and substrate consolidation device of the present invention includes a bottom ring 1, a turntable 2, an adhesive coating mechanism, an elastic magnetic pressure ring 3 and an electromagnetic ring 4, and the center of the upper surface of the turntable 2 is There is a positioning shaft 6 for installing and positioning the base body 5 of the grinding wheel. The bottom ring 1, the turntable 2, the elastic magnetic pressure ring 3 and the electromagnetic ring 4 are all arranged on the same axis. The elastic magnetic pressure ring 3 is arranged on the turntable 2, and there are 4 sets of electromagnetic rings Outside the elastic magnetic pressure ring 3 , the adhesive coating mechanism is arranged on the side of the turntable 2 , the bottom ring 1 is arranged on the lower surface of the turntable 2 , and the bottom ring 1 is provided with an annular air flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com