Rolling type leveling mechanism

A roll-pressing and flat-rolling technology, applied in the field of lamination equipment, can solve the problems of many bubbles and low lamination efficiency, and achieve the effect of lamination flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

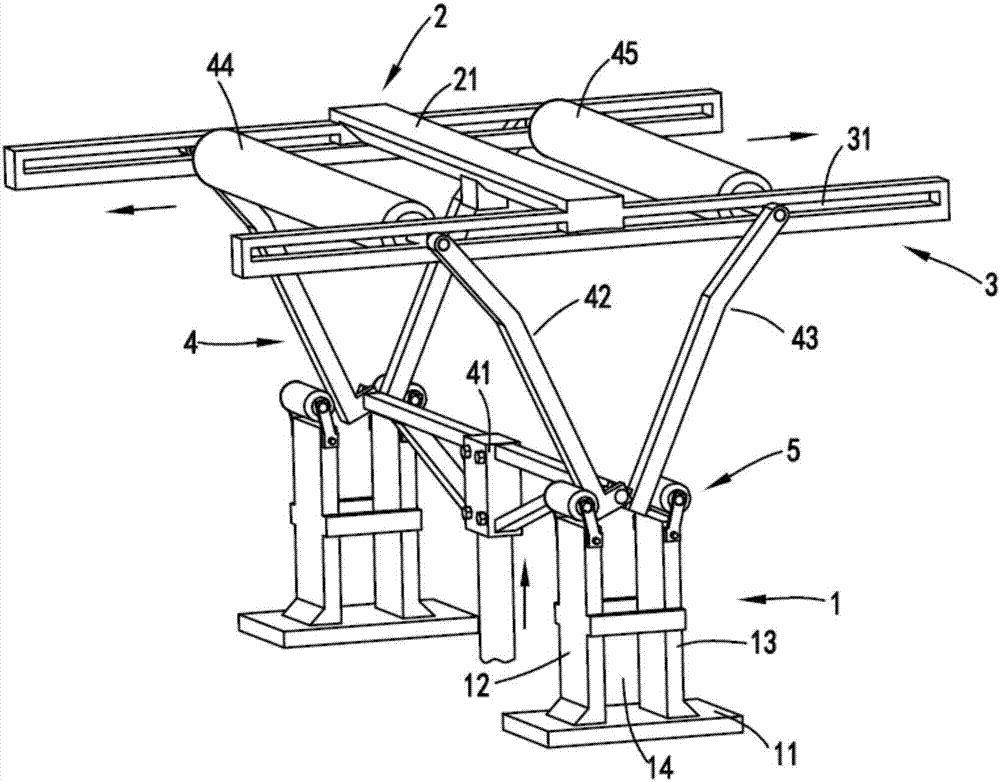

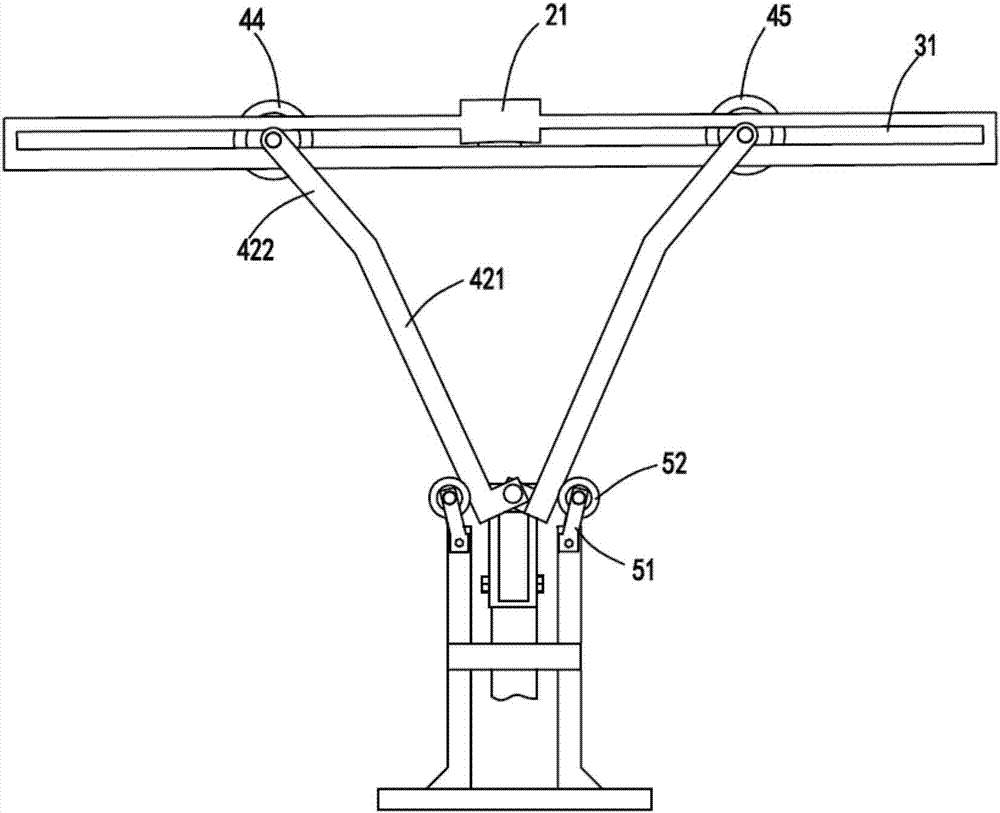

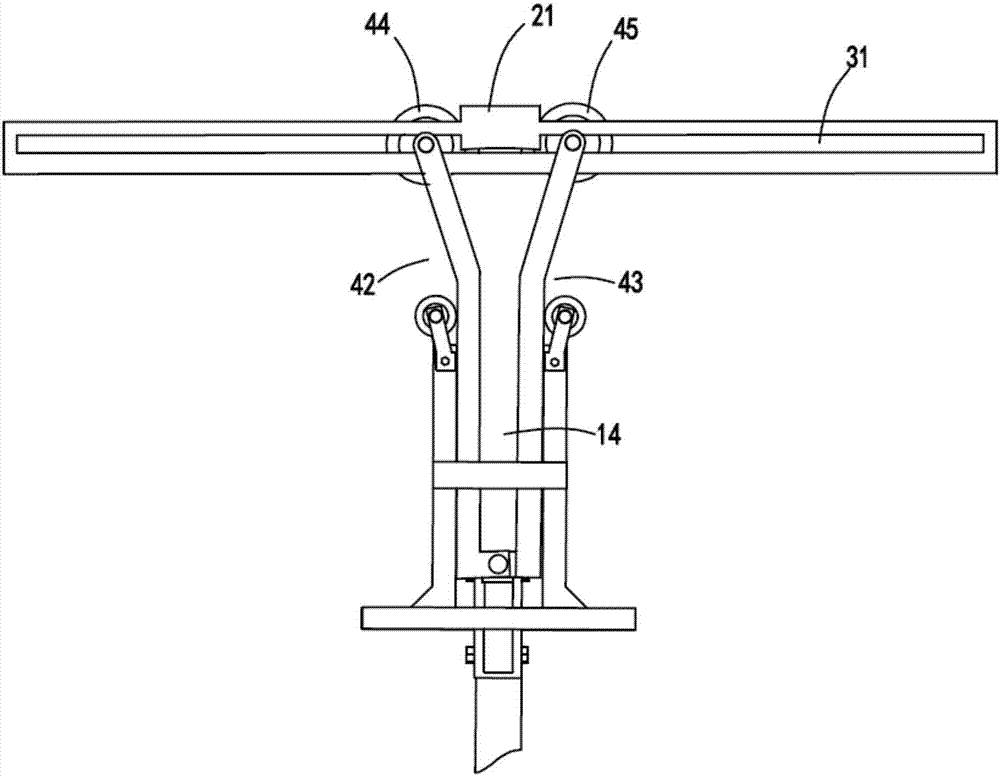

[0024] figure 1 It is a structural schematic diagram of a roller-type smoothing mechanism, figure 2 It is a schematic diagram of the smoothing roller a and smoothing roller b of the laminating device sliding to both sides, image 3 It is a schematic diagram of the front view of the initial state of the roller-type smoothing mechanism, Figure 4 Schematic diagram of the structure of the bonding device, Figure 5 It is a schematic diagram of the use state of the present invention. Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a rolling type smoothing mechanism includes a limit device 1, a support device 2 for supporting the film, a guide device 3 arranged on both sides of the support device, and a guide device 3 for driving the support device 2 and a support device. The film on the device 2 moves upward along the limit device 1 to make the film contact with the workpiece to be filmed, and then moves to both sides along the guide device 3 so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com