Turning clamp

A technology of flipping fixtures and inner tubes, which is applied in the field of fixtures and tooling, can solve problems such as secondary clamping, and achieve the effects of convenient workpieces, improving labor productivity, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

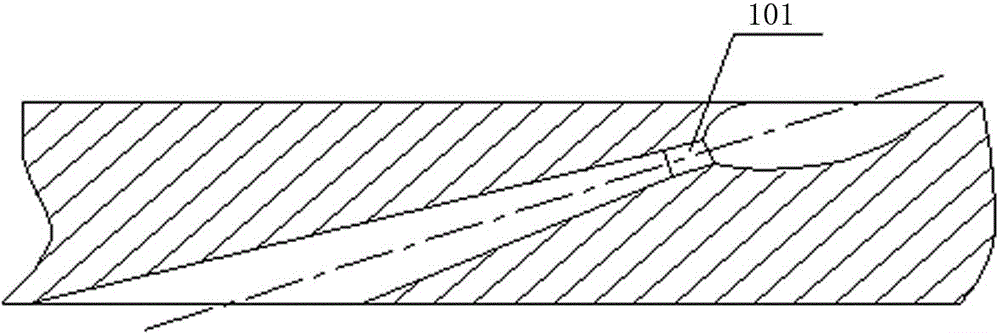

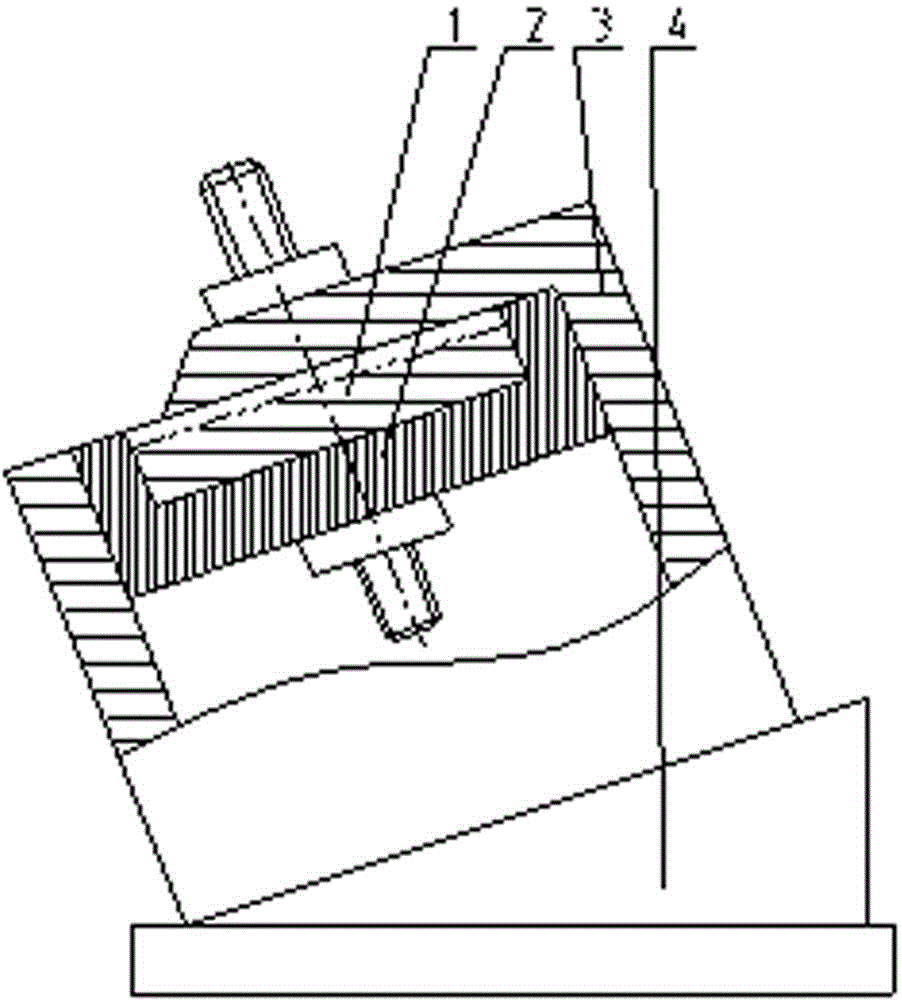

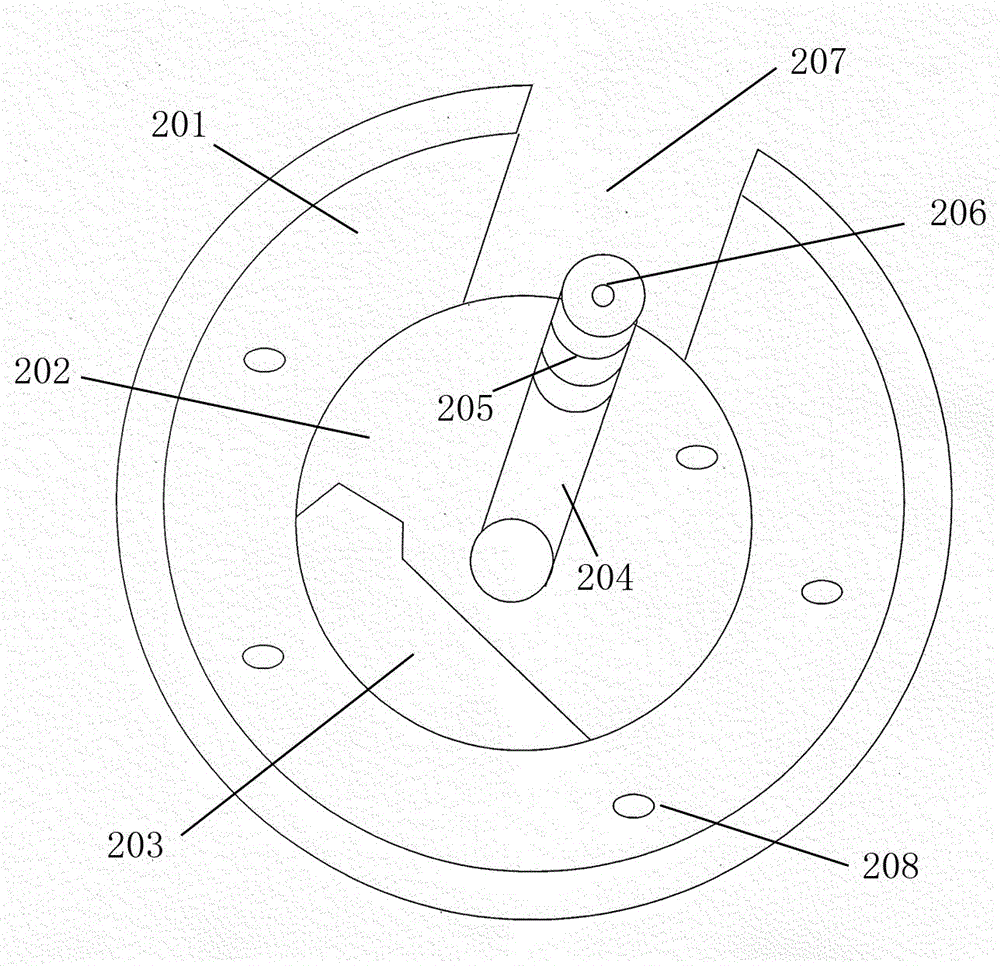

[0029] like Figure 1-5 As shown, the main frame 3 is installed on the base 4, the overturned inner tube 2 is installed in the main frame 3, and the workpiece turbine cover is fixed on the overturned inner tube 2, and the overturned inner tube and the workpiece are respectively axially positioned, end-face positioned and angularly positioned; Axial positioning, end face positioning and angular positioning are respectively performed on the flip inner tube and the main frame described above. .

[0030] The overturned inner tube and the workpiece are axially positioned through the inner hole; the inner end face of the overturned inner tube is clamped with the end face of the workpiece for end face positioning; the workpiece is provided with an angular positioning hole; the overturned inner tube and the workpiece pass through the corner Angular orientation to the pilot hole.

[0031] The overturned inner tube and the main frame end face are clamped for end face positioning, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com