Modular robot welding tongs

A robotic welding tong and modular technology, applied in the field of processing and welding, can solve the problems of inaccurate welding, missing welding, and wrong welding of the modular robot welding tongs, and achieve the effects of light weight, flexible operation and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

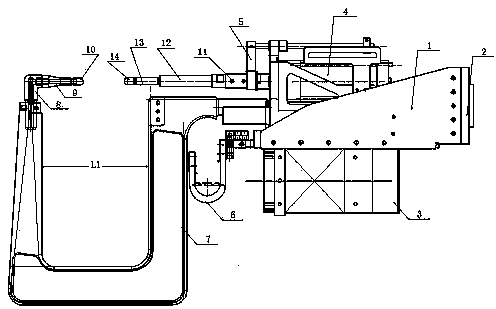

[0018] further as figure 1 In the use process shown, the upper welding arm and the lower welding arm are powered by the cylinder 4. Using this structural design, the trajectory of the upper welding arm or the lower welding arm can be quickly and accurately controlled to complete the welding action.

[0019] The invention has reasonable structural design, high welding precision, improved work rate and product quality, and meets the welding structure requirements of the existing automatic production line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com