Automatic stop finger mechanism of bending machine

A bending machine and automatic transmission technology, applied in the field of bending machines, can solve the problems of low positioning accuracy, unfavorable precise fine-tuning, cost overturning, etc., to achieve the effect of ensuring processing quality, improving positioning accuracy, and ensuring positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

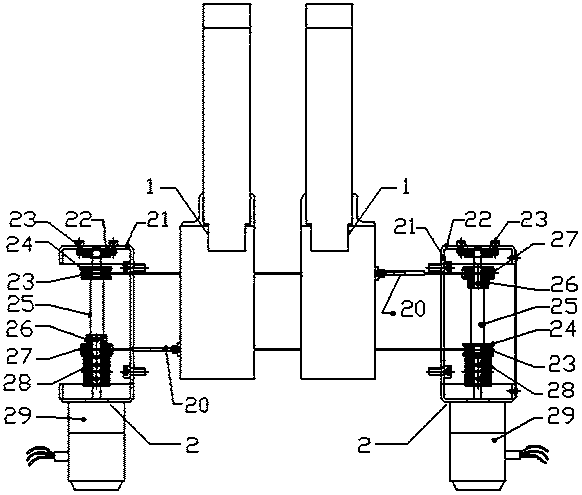

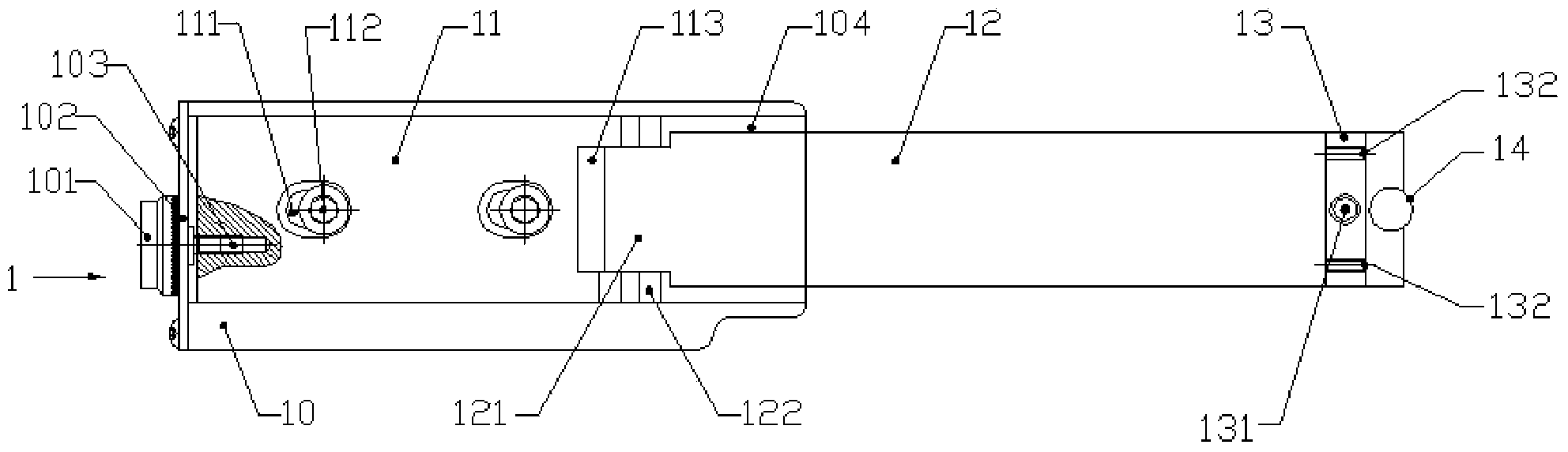

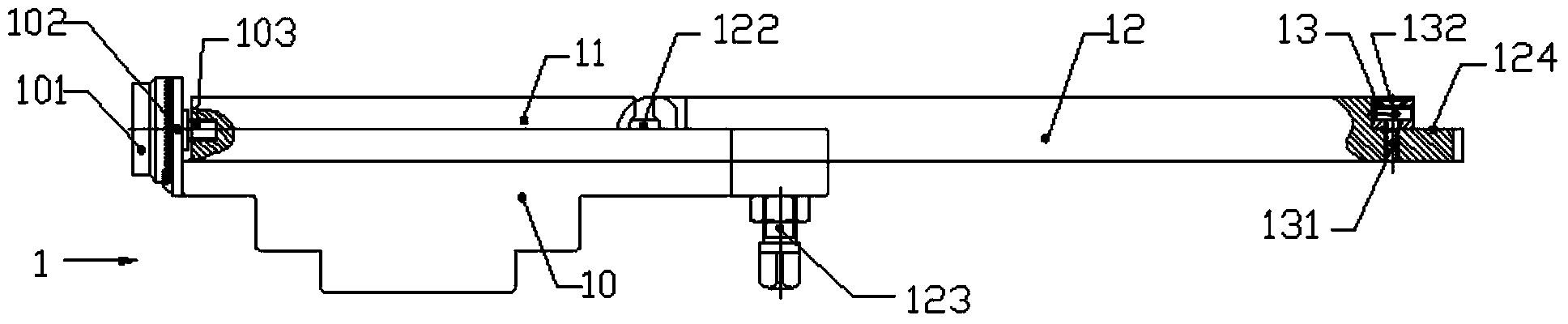

[0023] Such as figure 1 As shown, an automatic finger locking mechanism for a bending machine includes finger driving devices 2 arranged on the left and right sides of the bending machine. Finger 1, the finger 1 is slidably arranged on the Z-axis slide rail of the bending machine, and is driven by the finger drive device 2 to move left and right along the Z-axis slide rail.

[0024] Such as figure 1 As shown, specifically, the finger driving device 2 includes a driving base 21, the driving base 21 has an approximate U-shaped structure, and the driving shaft 25 is vertically and rotatably installed on the driving base 21, and the driving shaft 25 is driven by Driven by a motor 29, the driving shaft is axially equipped with a driving wheel 26 and a driven wheel 24, the driving wheel and the driving shaft are fixed, a bearing 23 is arranged between the driven wheel and the driving shaft, and the driving shafts on the left and right sides The upper driving wheel and the driven w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com