Flattening device of flour slices

A flour and leveling technology, which is applied in the fields of dough processing, baking, food science, etc., can solve the problems of improper leveling of noodles, formation of piles, and the position of the knife holder is not adjustable, and achieves a simple structure, smooth surface, and is conducive to leveling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

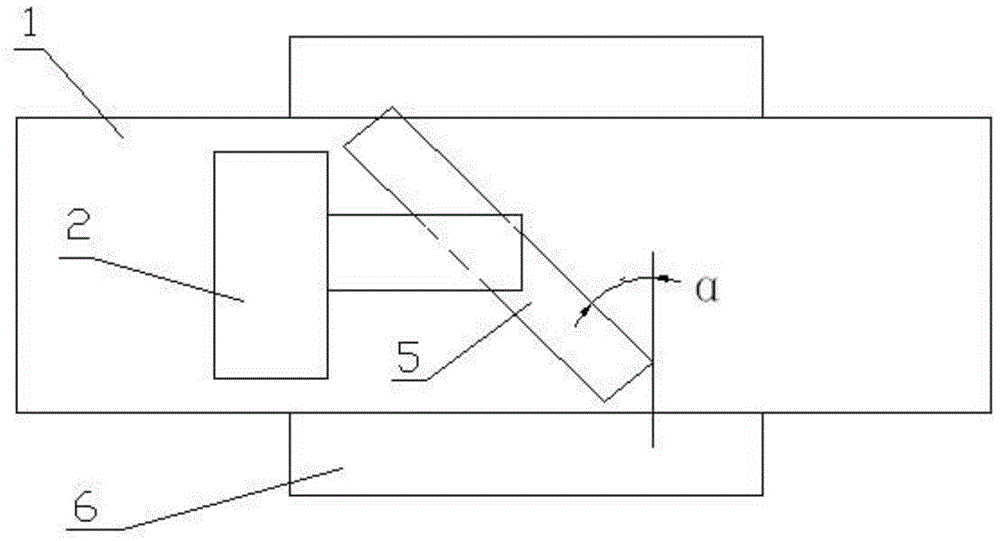

[0025] combine figure 1 , figure 2 : a flat device for flour flakes, comprising a belt conveyor 1, the belt conveyor 1 is provided with a support 2, the support 2 is provided with a chute, the chute can be provided with a slide block 3, and the slide block 3 is provided with A fixing bolt 4 is arranged on it, and a blade 5 is also arranged on the slider 3, and there is a gap between the blade 5 and the belt surface of the belt conveying device 1 . The distance between the blade 5 and the belt surface of the belt conveyor 1 is adjustable, which is suitable for leveling flour of different thicknesses.

[0026] The length direction of the blade 5 forms an included angle α with the width direction of the belt conveyor 1, and the value of the α is 55 degrees; in this way, the leveled flour can be better separated from the belt surface and transported away in time.

[0027] The length value of the projection of the blade 5 in the width direction of the belt conveyor 1 is greater ...

Embodiment 2

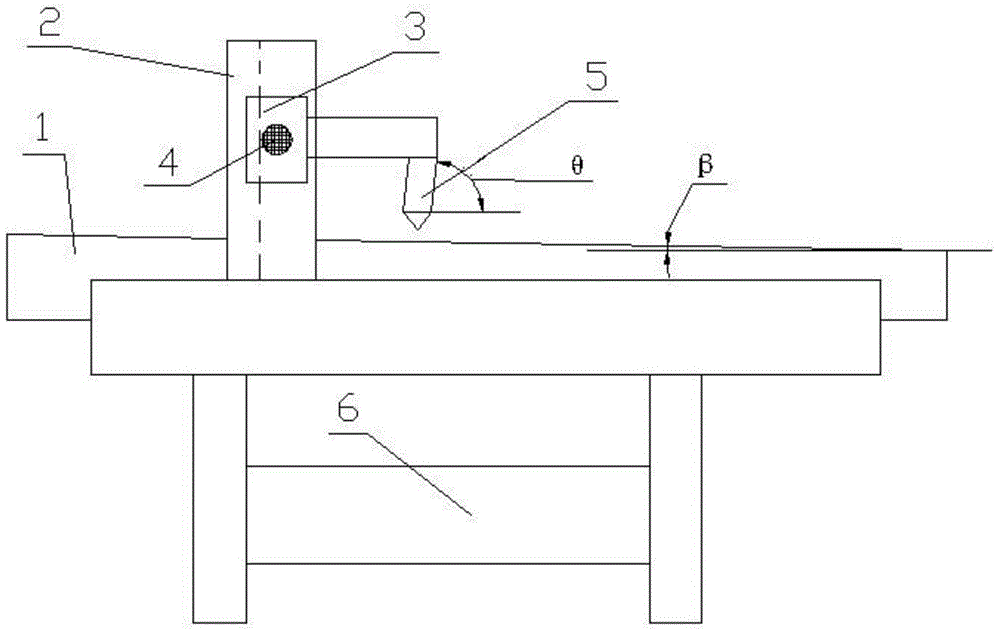

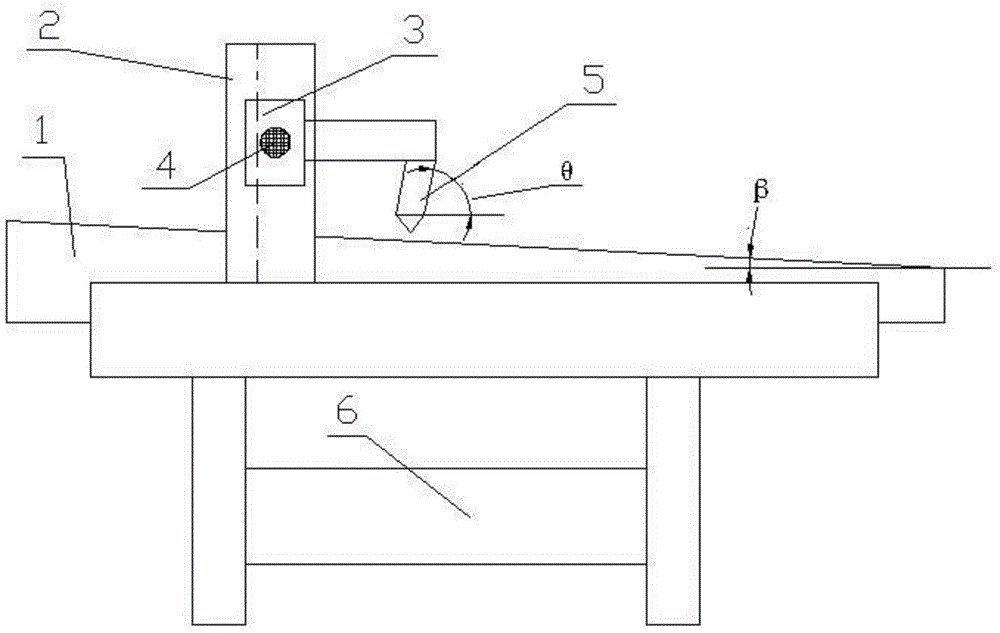

[0032] combine image 3 , Figure 4 : a flat device for flour flakes, comprising a belt conveyor 1, the belt conveyor 1 is provided with a support 2, the support 2 is provided with a chute, the chute can be provided with a slide block 3, and the slide block 3 is provided with A fixing bolt 4 is arranged on it, and a blade 5 is also arranged on the slider 3, and there is a gap between the blade 5 and the belt surface of the belt conveying device 1 . The distance between the blade 5 and the belt surface of the belt conveyor 1 is adjustable, which is suitable for leveling flour of different thicknesses.

[0033] The length direction of the blade 5 forms an included angle α with the width direction of the belt conveyor 1, and the value of the α is 18 degrees; in this way, the smoothed flour can be better separated from the belt surface and transported away in time.

[0034] The length value of the projection of the blade 5 in the width direction of the belt conveyor 1 is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com