Transverse edge cutting and stacking device of plywood edge cutting machine

An edge trimming machine, plywood technology, applied in other plywood/plywood appliances, wood processing appliances, manufacturing tools, etc., can solve problems such as damage to the surface of the plywood, tilting of the plywood, etc., and achieve the effect of ensuring quality and surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

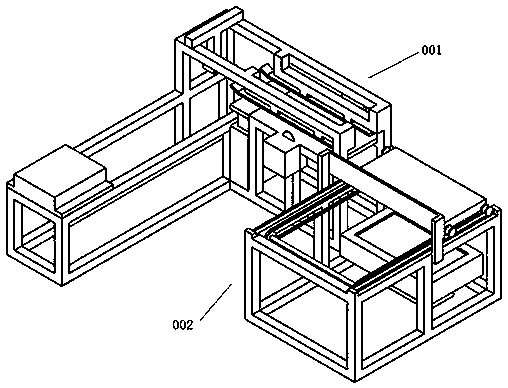

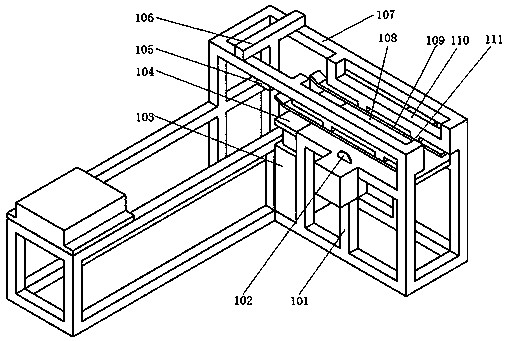

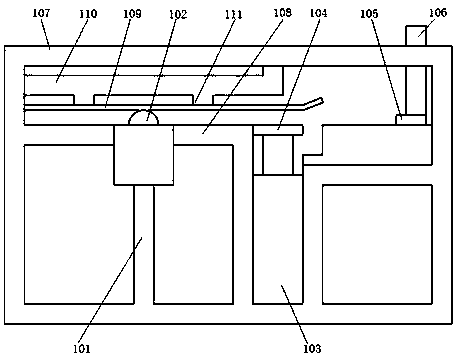

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 as well as Figure 10 As shown, the plywood trimming machine lateral trimming stacking device includes a lateral trimming device 001 and a stacking device 002, and the lateral trimming device 001 includes a trimming frame 101, a support table 108 and a trimming saw 102, The front side of described supporting platform 108 is provided with trimming lifting platform 104, and trimming lifting platform 104 is movably connected on the lifting base 103, and trimming lifting platform 104 is supported by cylinder, and cylinder is fixedly connected on the lifting base 103; The device 002 includes a blanking frame 201 and a stacking lifting platform 208. A movable support plate 207 is movable on the top of the blanking frame 201. A transmission device is provided on the top of the blanking frame 201. The movable support plate 207 and the transmission device conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com