Potentiometer processing system and method

A technology for processing systems and potentiometers, applied in the directions of instruments, measuring electricity, measuring electrical variables, etc., can solve the problems of continuously adjustable reciprocating speed of the sliding head of the potentiometer under test, low accuracy, and narrow adjustable range. Achieve the effect of high accuracy, guaranteed accuracy and wide operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

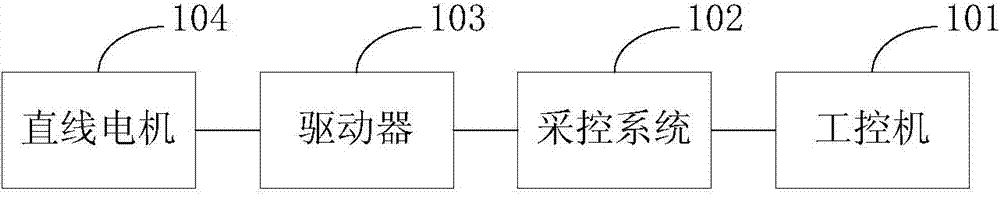

[0048] like figure 1 As shown, it is a schematic structural diagram of a potentiometer processing system in the present invention. The processing system can be applied to a potentiometer life test system, and the processing system can specifically include: an industrial computer 101 connected in sequence, an acquisition and control system 102, and a driver 103 and linear motor 104, wherein,

[0049] In practical applications, before the test bench (that is, the tooling used to install the potentiometer under test) is not connected, the operator can first start the potentiometer life processing system, and after completing the initialization of the system, the potentiometer can be processed The linear motor in the system is connected to the test bench installed with the potentiometer under test, after which subsequent operations can be carried out.

[0050] The embodiment of the present invention utilizes the characteristics of simple structure and high positioning accuracy of t...

Embodiment 2

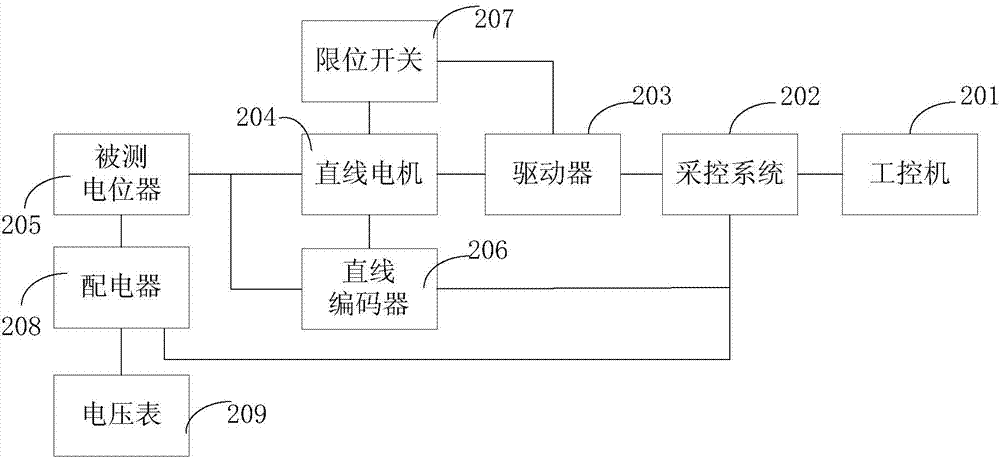

[0061] like figure 2 As shown, it is a schematic structural diagram of another potentiometer processing system of the present invention. This processing system can be applied to potentiometer life testing, and its specific structure can include:

[0062] The industrial computer 201, acquisition and control system 202, driver 203 and linear motor 204 connected in sequence are installed on the test bench ( figure 2 The measured potentiometer 205 on the), the linear encoder 206 connected to the acquisition and control system 202, the linear motor 204 and the measured potentiometer 205 respectively, the limit switch 207 connected to the linear motor 204 and the driver 203 respectively , the distributor 208 connected to the measured potentiometer 205 and the acquisition and control system 202 , and the voltmeter 209 connected to the distributor 208 .

[0063] In the actual application of the embodiment of the present invention, the initial position information of the sliding hea...

Embodiment 3

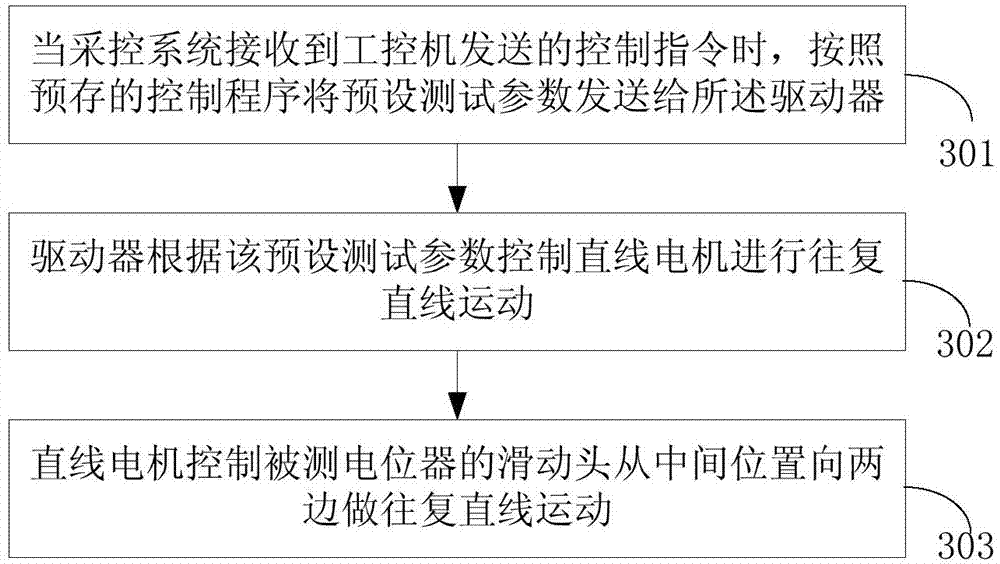

[0073] like image 3 As shown, it is a flow chart of a potentiometer processing method of the present invention, which is applied to the potentiometer processing system described in the above-mentioned embodiments. When the potentiometer processing system includes an industrial computer, an acquisition and control system, a driver and a linear When the motor is used, the specific steps of the method may include:

[0074] Step 301: When the acquisition and control system receives the control instruction sent by the industrial computer, it sends the preset test parameters to the driver according to the pre-stored control program.

[0075]Wherein, the preset test parameters include the frequency, displacement and times of the reciprocating linear motion of the sliding head of the potentiometer under test.

[0076] In the embodiment of the present invention, when the system is applied to the LabVIEW software platform, before step 301 is executed, the system software is usually st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com