Method for predicting shelf-life stability of sterilized milk

A technology for sterilized milk and shelf life, which is applied in the direction of measuring device, scattering characteristic measurement, particle size analysis, etc., and can solve the problems of long time and low accuracy of the method for measuring the stability of sterilized milk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The sample is placed in the test room under aseptic operation and put into the stability analyzer. The amount of the sterilized milk sample added is 20.0ml, and the added height is 45.0mm. Set the scan interval to 1min, the temperature of the sample chamber to 35°C, scan and measure for 24 hours, analyze the data of the average scattered light change rate (△BS) within 24 hours through TurbiscanEasysoft software, and obtain the stability kinetic parameter (STI) value 0.8, it is determined that the stability is good within 6 months of its shelf life.

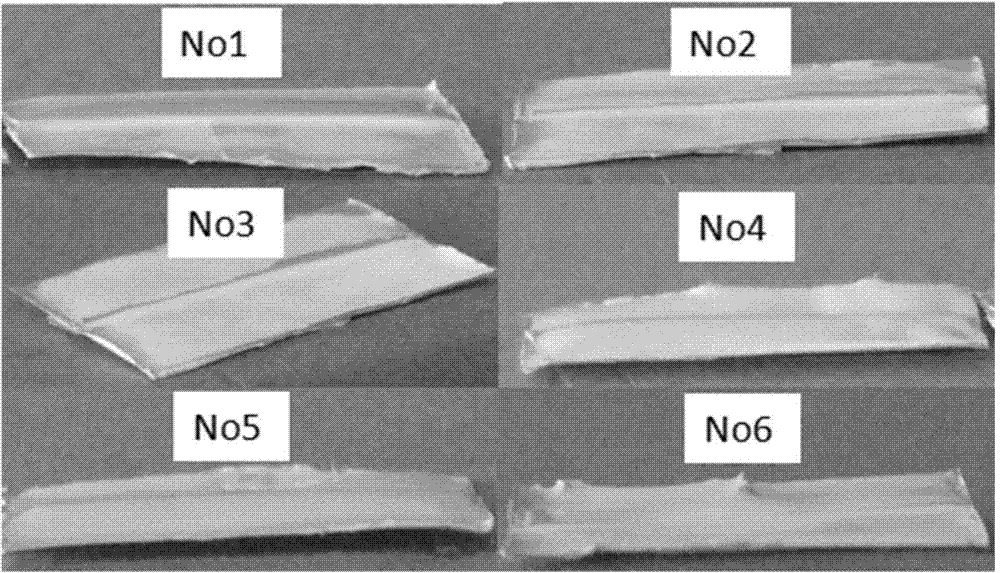

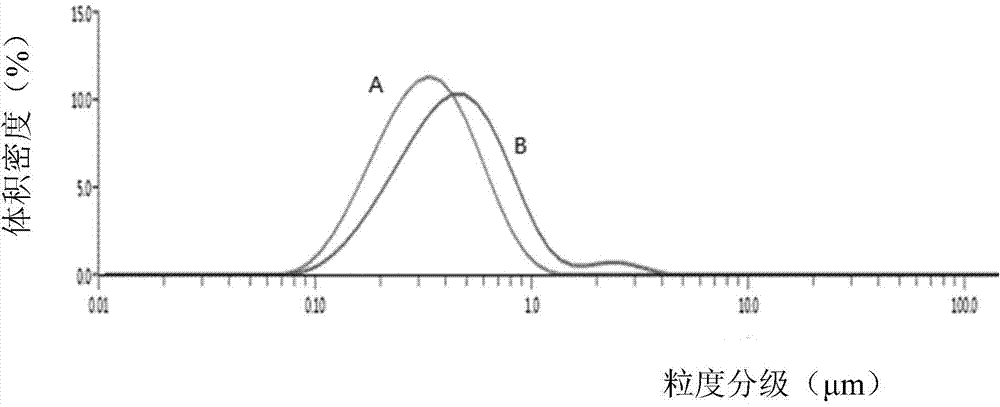

[0034] Implementation effect: such as figure 1 , 2 (Curve A represents the initial stage of the sample, and Curve B represents the time of 6 months), when the shelf life is reached, there is less residual fat layer in the package, and the particle size distribution does not change much compared with the initial stage of the product. It shows that the above measurement results are basically consistent with the actua...

Embodiment 2

[0037] The sample is placed in the test room under aseptic operation and put into the stability analyzer. The amount of the sterilized milk sample added is 20.0ml, and the added height is 45.0mm. Set the scan interval to 20min, the temperature of the sample chamber to 25°C, scan and measure for 24 hours, analyze the data of the average scattered light change rate (△BS) within 24 hours through TurbiscanEasysoft software, and obtain the stability kinetic parameter (STI) value 1.17, it is determined that its stability is good within 6 months of the shelf life.

[0038] Implementation effect: such as figure 1 , 3 (Curve A represents the initial stage of the sample, and Curve B represents the time of 6 months), when the shelf life is reached, there is less residual fat layer in the package, and the particle size distribution does not change much compared with the initial stage of the product. It shows that the above measurement results are basically consistent with the act...

Embodiment 3

[0041] The sample is placed in the test room under aseptic operation and put into the stability analyzer. The amount of the sterilized milk sample added is 20.0ml, and the added height is 45.0mm. Set the scan interval to 120min, the temperature of the sample chamber to 40°C, scan and measure for 24 hours, analyze the data of the average scattered light change rate (△BS) within 24 hours through TurbiscanEasysoft software, and obtain the stability kinetic parameter (STI) value 1.25, it is determined that its stability is good within 6 months of the shelf life.

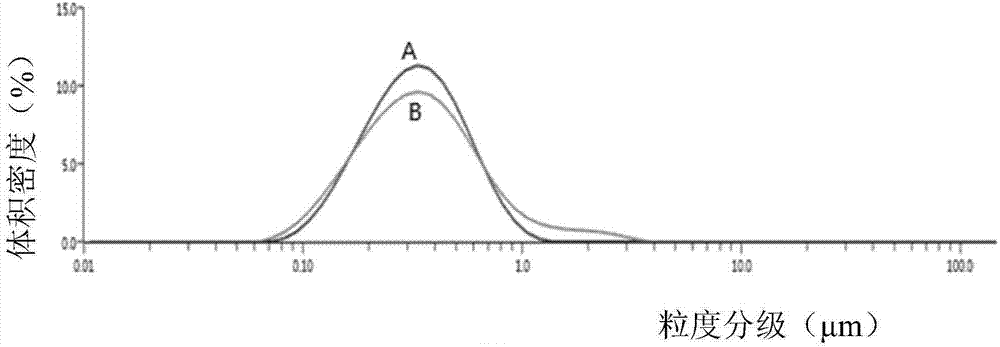

[0042] Implementation effect: such as figure 1 , 4 (Curve A represents the initial stage of the sample, and Curve B represents the time of 6 months), when the shelf life is reached, there is less residual fat layer in the package, and the particle size distribution does not change much compared with the initial stage of the product. It shows that the above measurement results are basically consistent with the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com