Strain gauge assembly and test method for testing thermoset cast pbx cure stress

A technology for curing stress and strain gauges, applied in the measurement of elastic deformation force by measuring gauges, and the measurement of permanent deformation force by measuring gauges, etc., can solve the problem of inability to obtain the curing stress of explosives, and achieve stability and reliability. stability problem, constant gage factor, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

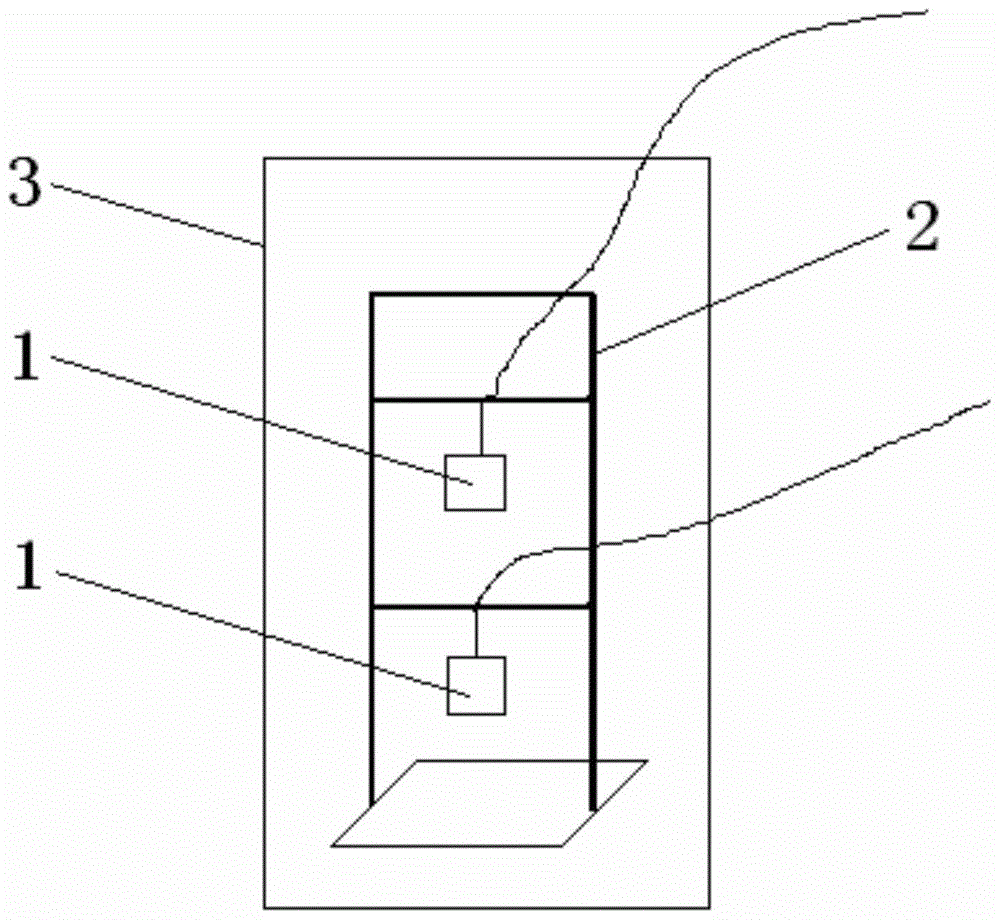

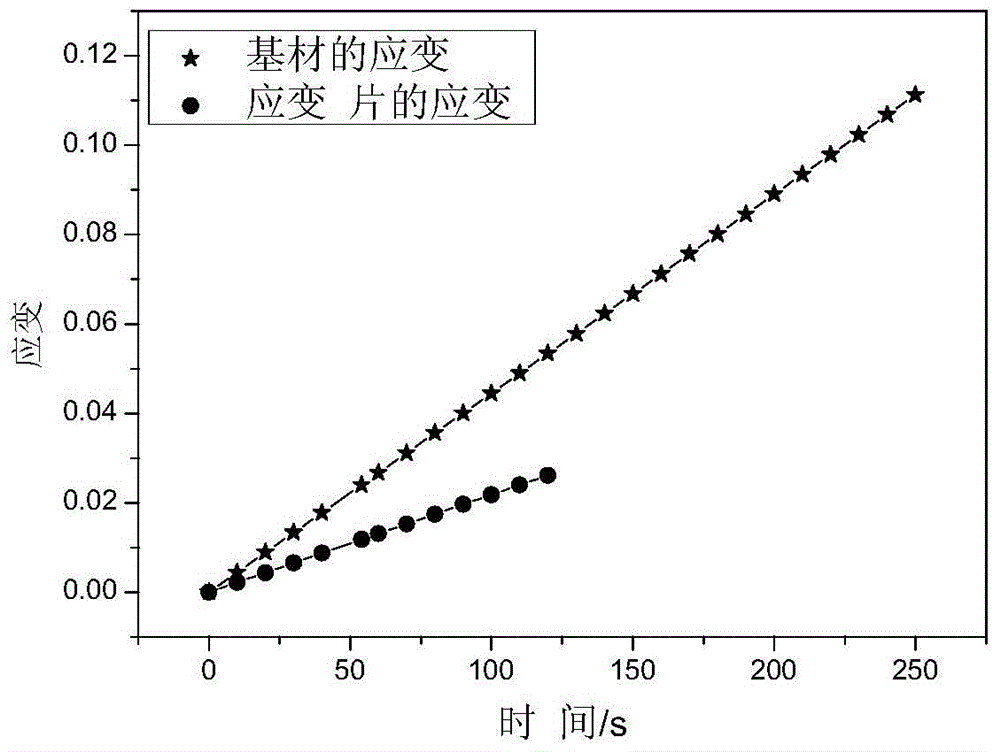

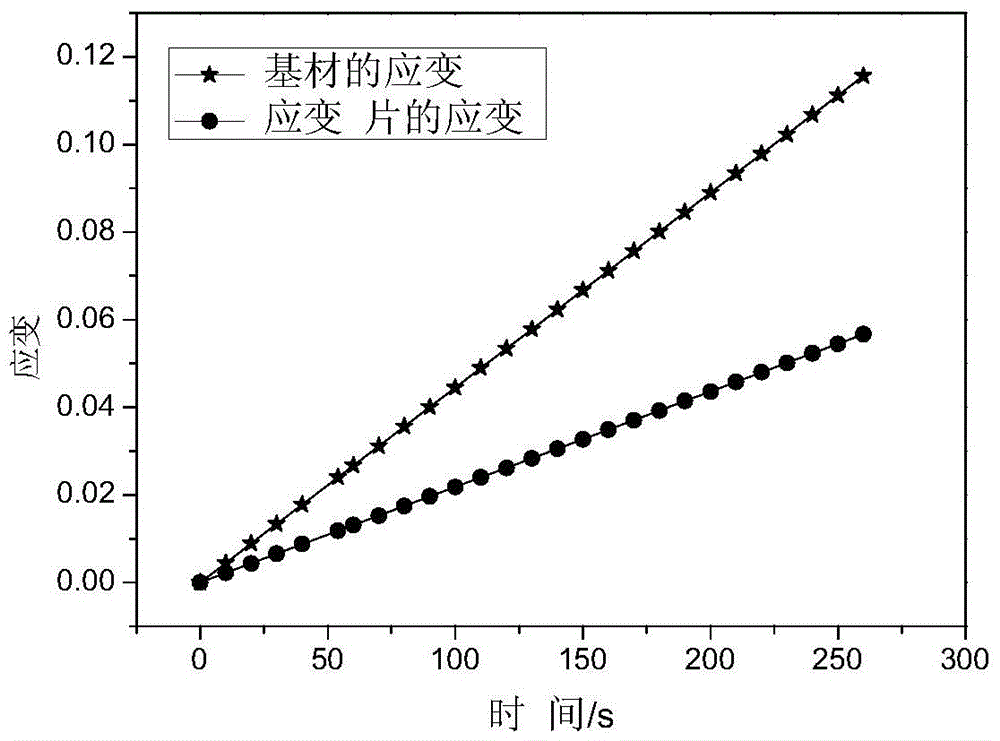

[0061] In this embodiment, YE3818 dynamic strain gauge (universal dynamic strain amplifier) and 120Ω BB120-44A (11) 250 high temperature strain gauge are used to test the curing stress at two different positions in the body of the 1000ml thermosetting PBX curing process, wherein The curing temperature was 80°C. The test data is collected by GEN5i of HBM Company, the collection frequency is 10 / s, and the collection period is 18h.

[0062] The composition of thermosetting cast PBX is: hydroxyl-terminated polybutadiene, aluminum powder, dioctyl adipate, 2,4-toluene diisocyanate, triphenylbismuth, RDX and OCTOGEN, with a density of 1.62g / cm3~1.70g / cm3.

[0063] The basic performance parameters of the substrate are: density 1.64g / cm3; tensile modulus 15.6Mpa; thickness 2mm, length 12mm, width 6mm; strain gauge length 8mm, width 4mm.

[0064] Test steps:

[0065] (1) Make 10 substrates of 2.0×6.0×12.0mm, and calibrate the gauge factor between the substrate and the strain gauge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com