Machine speed control system of chain grate

A technology of control system and chain grate, which is applied in the direction of furnace type, furnace, lighting and heating equipment, etc., can solve the problems of red material discharge from ring cooler, burnt grate bed equipment, waste of energy, etc., to prevent waste of energy, The thickness is reasonable and the effect of ensuring the quality of the dry ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

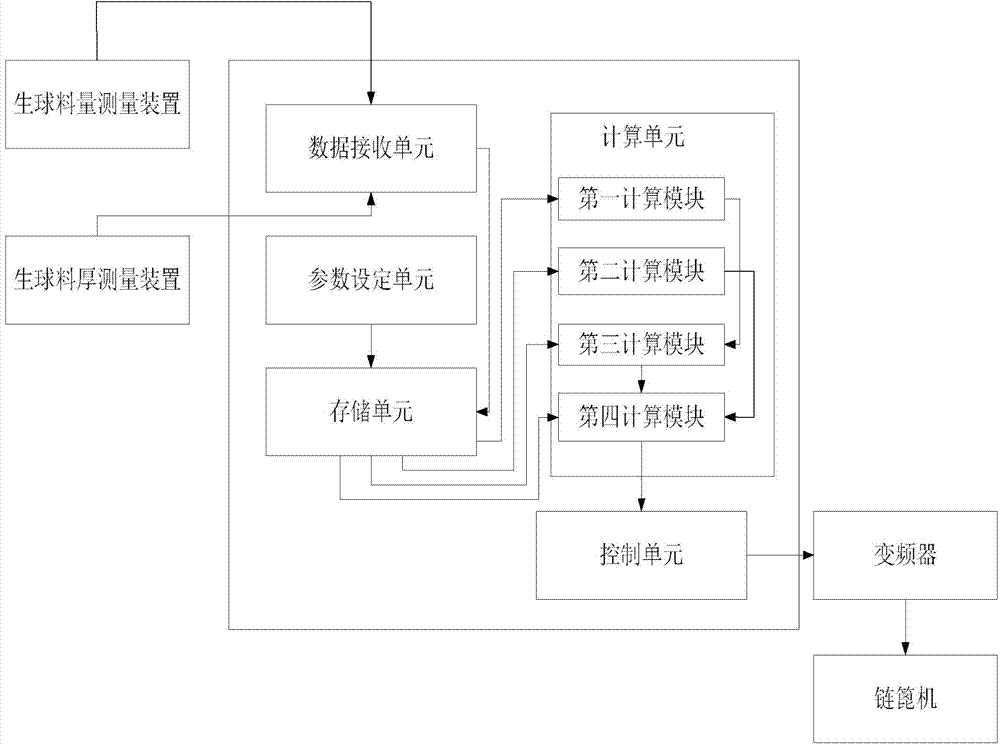

[0011] see figure 1 , The embodiment of the present invention provides a speed control system for a grate machine, comprising: a measuring device for the amount of green pellets, a measuring device for the thickness of green pellets, a frequency converter and a control device. The green pellet volume measuring device, the frequency converter and the green pellet thickness measuring device are respectively connected to the control device; the green pellet thickness measuring device measures at least three green pellet thickness measurement values instantaneously, that is, the green pellet thickness measuring device simultaneously Measure the thickness value of the green ball material layer at least three different positions on the grate material layer, and the thickness value is the measured value of the green ball material thickness. The frequency converter is connected with the chain grate through the drive motor.

[0012] see figure 1 , in this embodiment, the control de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com