Electronic expansion valve

An electronic expansion valve and valve body technology, applied in the field of control valves, can solve the problems of increasing the adjustment times of the expansion valve, reducing the curve adjustment accuracy, control waste, etc., and achieving the effects of reducing the adjustment times, reducing energy consumption, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

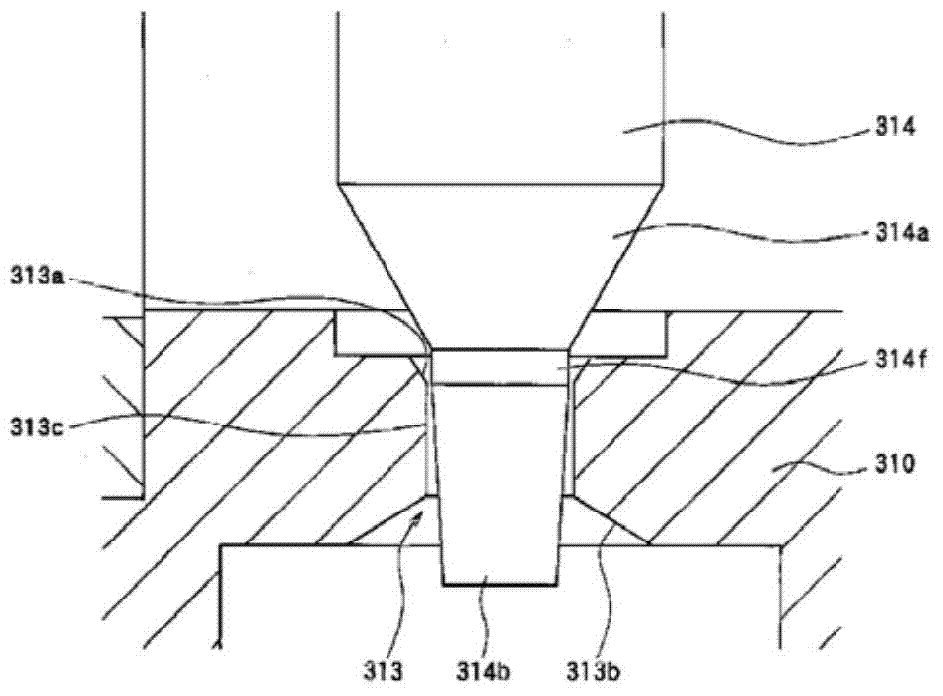

[0039] Please refer to image 3 , image 3 A structure diagram of a typical electronic expansion valve given in the present invention.

[0040] The electronic expansion valve generally includes a coil 100 arranged on the outer periphery of the metal isolation cover 300 and a magnetic rotor 200 arranged on the inner periphery of the metal isolation cover 300. The coil 100 and the magnetic rotor 200 cooperate together and are equivalent to a stepping motor to constitute the driving part of the electronic expansion valve. .

[0041] The valve body 400 with the flow channel inlet 401 and the flow channel outlet 402 is airtightly welded with the isolation cover 300 to form an inner cavity 500 . The two connecting pipes 600 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com