Vertical lifting oil plane carburetor

A technology of carburetor and oil lifting, which is applied in the direction of machines/engines, etc. It can solve the problems of short float movement control stroke, inability to accurately control oil level, and inability to provide reliable sealing, so as to avoid no oil intake or oil leakage, The effect of precisely controlling the height of the oil level and eliminating potential safety hazards in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

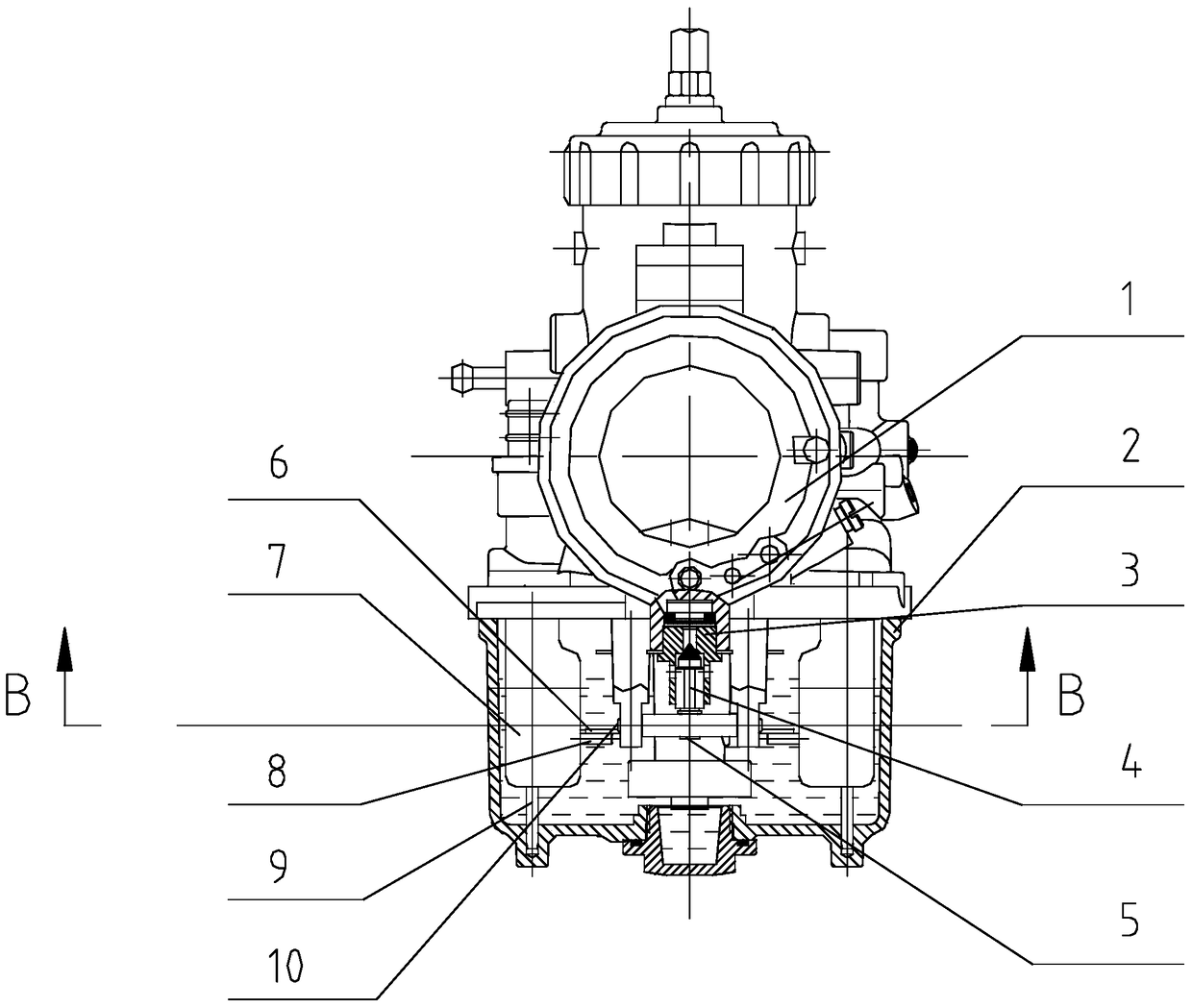

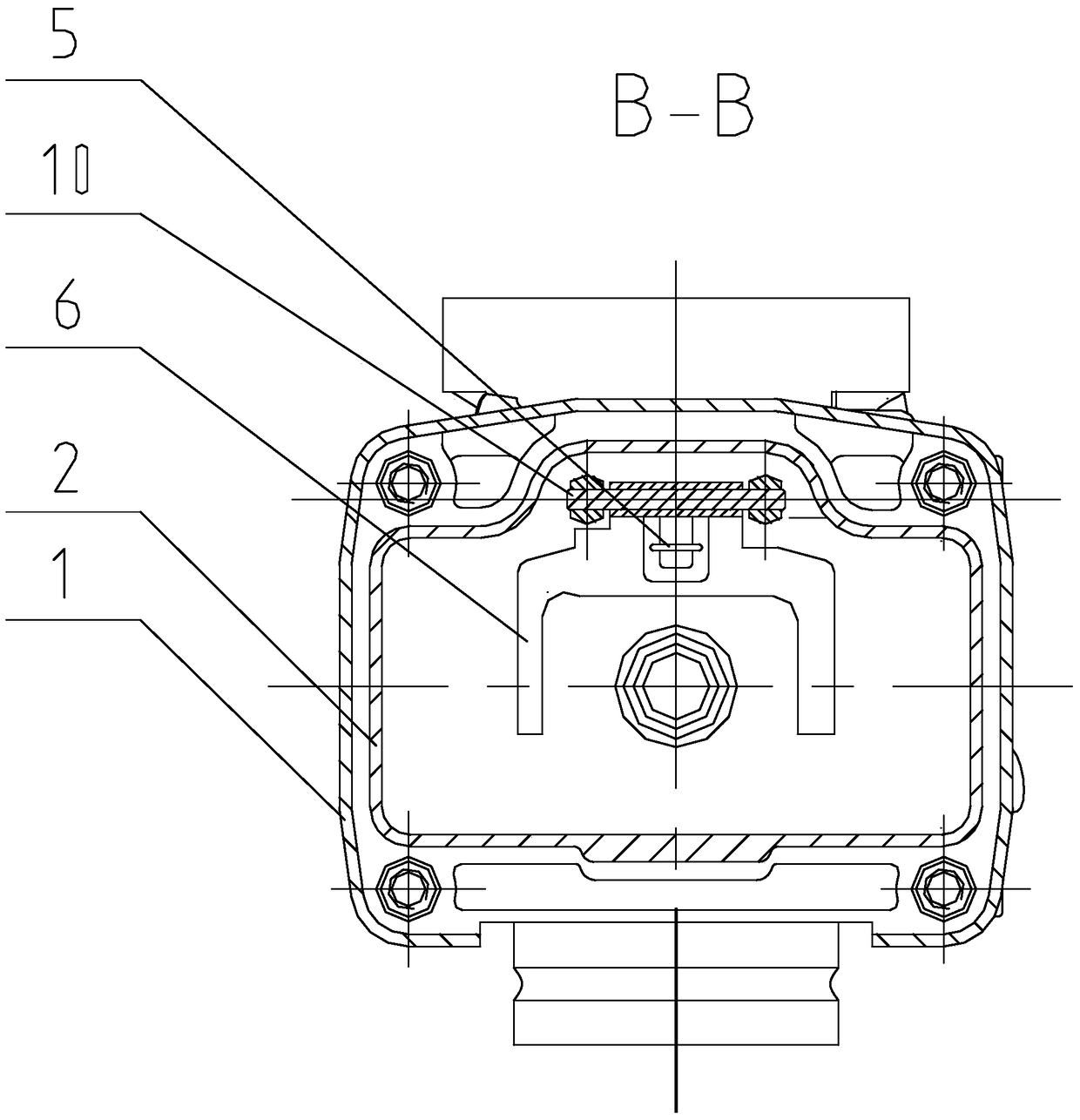

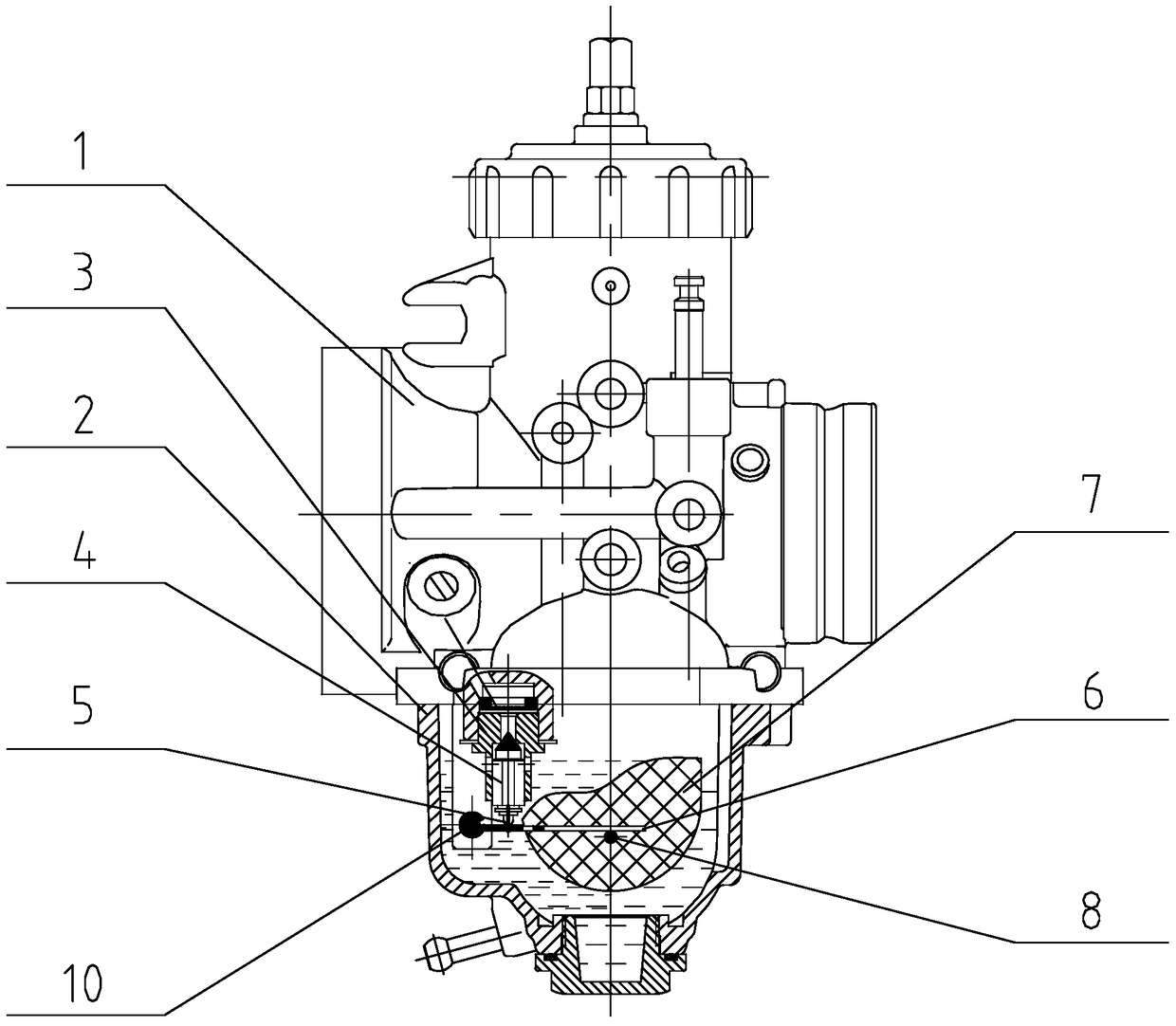

[0030] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the description:

[0031] Such as figure 1 - Figure 9 As shown, it is a schematic structural diagram of an embodiment of a vertical lifting oil plane carburetor provided by the present invention. In the figure, a carburetor includes a carburetor body 1, and is characterized in that: the carburetor Body 1 is equipped with carburetor float chamber 2, oil inlet check valve seat 3, oil inlet valve needle 4, oil inlet valve needle hook 5, float rocker arm 6, independent float 7, float lifting guide shaft 9, float pin 8. Float rotating shaft 10; one end of the oil inlet check valve seat 3 is connected with the external oil inlet pipeline, and the other end is set in the float chamber 2 of the carburetor, and the oil inlet check valve seat 3 is provided with a There is an axial oil inlet hole 11 for communicating with the external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com