spark ignition multi-cylinder engine

A spark ignition, engine technology, applied in spark ignition controllers, engine ignition, engine components, etc., can solve problems such as vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

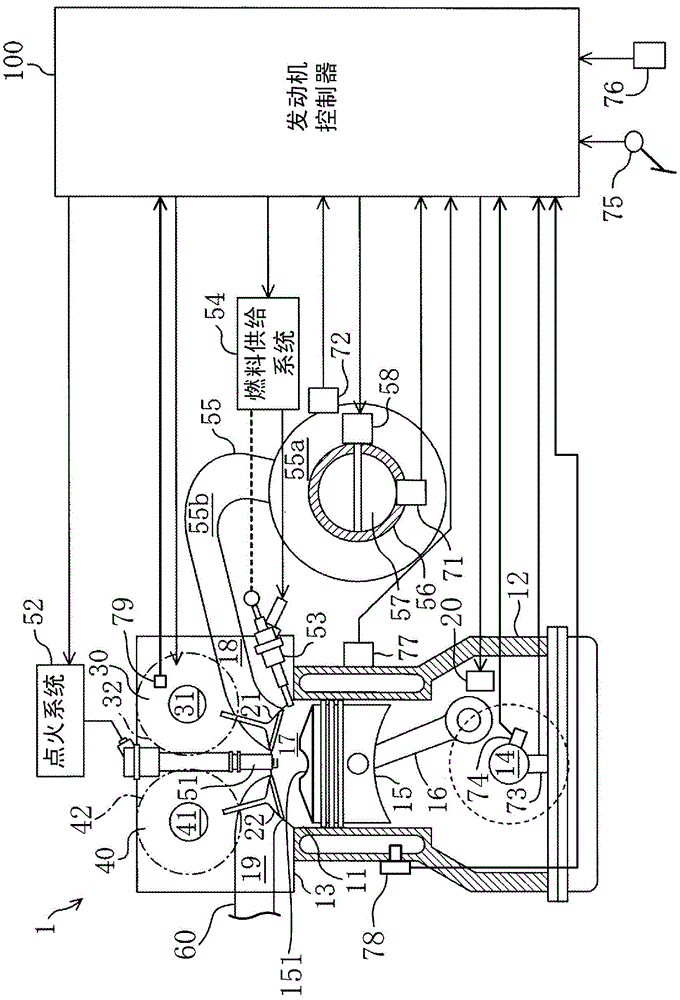

[0047] Embodiments of a spark ignition type multi-cylinder engine will be described below based on the drawings. The following descriptions are examples. Such as figure 1 As shown, the engine system has an engine 1 , various actuators accompanying the engine 1 , various sensors, and an engine controller 100 that controls the actuators based on signals from the sensors. This engine system includes a high compression ratio engine 1 having a geometric compression ratio of 13 to 20 (for example, 14).

[0048] Engine 1 is a spark ignition four-stroke internal combustion engine, figure 1 Although only one cylinder is shown in FIG. 1 , there are four cylinders 11 of the first to fourth cylinders arranged in-line. However, the engine to which the technology disclosed in the present invention is applicable is not limited to the in-line four-cylinder engine. The engine 1 is mounted in a vehicle such as an automobile, and its output shaft is not shown, but is connected to drive wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com