Single-tube beam capable of releasing temperature stress and suitable for transformer substation continuous rigid frame

A temperature stress and substation technology, which is applied to building insulation materials, building components, buildings, etc., can solve problems such as the instability of the end support foundation, and achieve the effect of eliminating potential safety hazards and reducing the pull-out force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

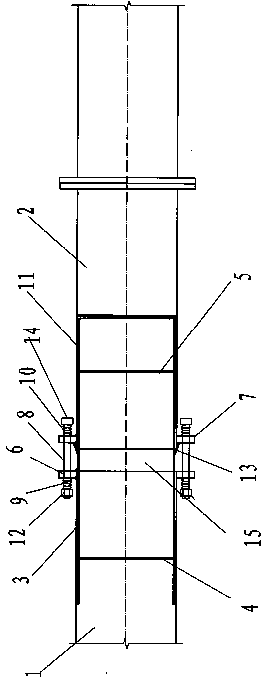

[0010] The present invention is described in detail below in conjunction with accompanying drawing:

[0011] A substation continuous rigid frame single-tube beam capable of releasing temperature stress, including a single tube 2, an extended single tube 1 and a connecting tube 3; The inner wall of the right end of the pipe 3 is provided with a connecting pipe right reinforcement ring rib 5, an extended single pipe flange 6 is provided on the outer surface of the right port of the extended single pipe 1, and a flange 6 is provided on the outer surface of the left port of the single pipe 2. Single pipe flange 7, the left end of connecting pipe 3 is socketed in the right end pipe of extending single pipe 1, the left end of connecting pipe 3 is fixedly welded with the inner side wall of extending single pipe 1, and the right end of connecting pipe 3 is movably socketed In the left end pipe of the single pipe 2, a lubricating grease layer 11 is provided between the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com