Fastener plug-in curved metal roof and its construction method

A metal roof and plug-in technology, which is applied to roofs, roofs, and roof coverings using flat/curved panels, and can solve problems such as high cost, damage, and cumbersome construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

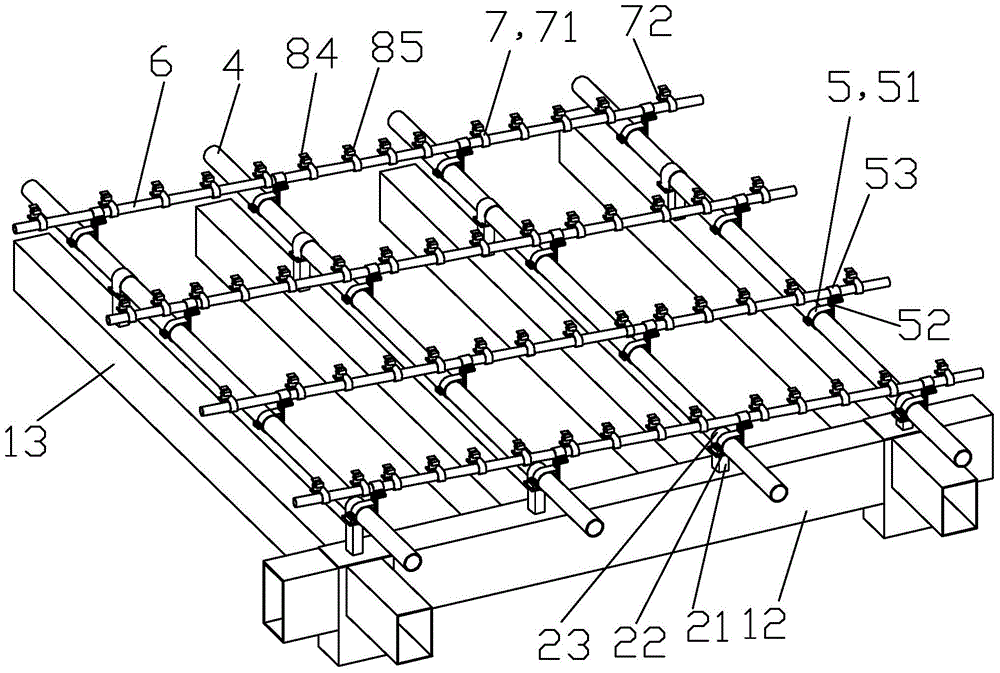

[0074] See Figure 1 to Figure 6 , the fastener plug-in type curved metal roof of this embodiment is mainly composed of a base frame 1, a main purlin support assembly 2, an extension connecting fastener 3, a main purlin 4, a primary and secondary purlin adapter assembly 5, a secondary purlin 6, and a secondary purlin The purlin panel adapter assembly 7, the roof panel assembly 8 and the sealing assembly 9 are composed.

[0075]The base frame 1 is composed of several interconnected units (also known as spans). Each unit is mainly composed of 4 supporting steel columns 11, 2 main beams 12 and more than 3 secondary beams 13, the number and spacing of the secondary beams 13 are determined according to the span of each unit according to the design. The quantity, height and installation position of the supporting steel column 11 on the roof of the civil structure are determined according to the design. Each supporting steel column 11 is fixedly installed by its lower end on the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com