Construction method of large-space metal spherical canopy reticulated shell for equipment storage

A large space, metal ball technology, applied in arched structures, dome structures, buildings, etc., can solve the problems of space and material waste, high cost, long construction period, etc., to achieve large free space, less internal support, The effect of long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

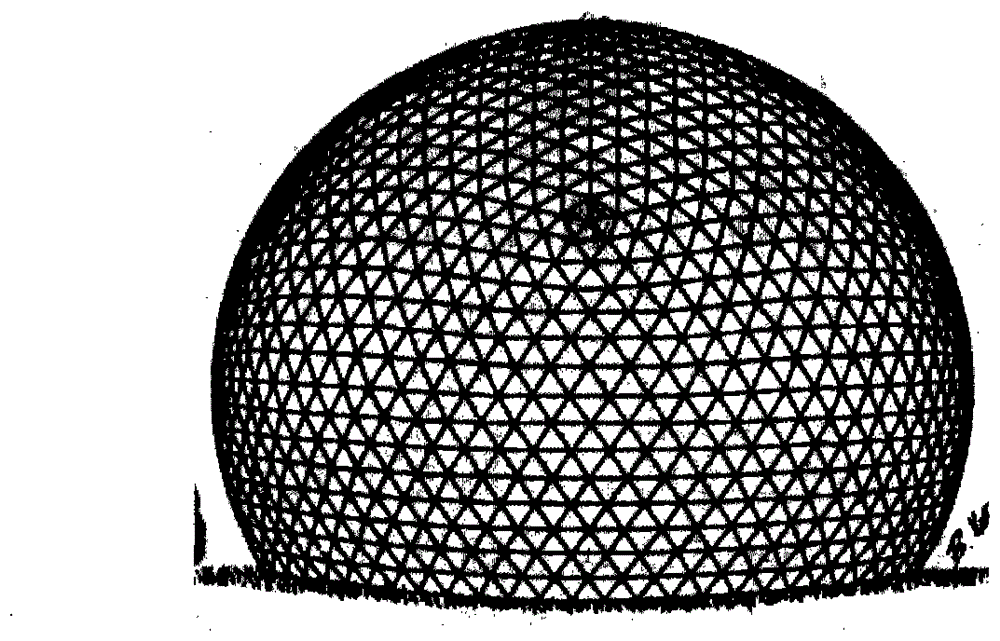

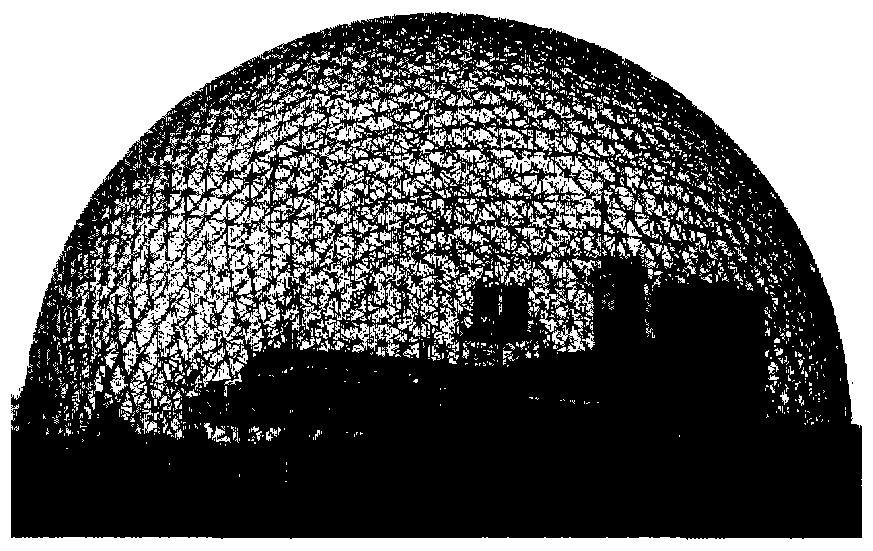

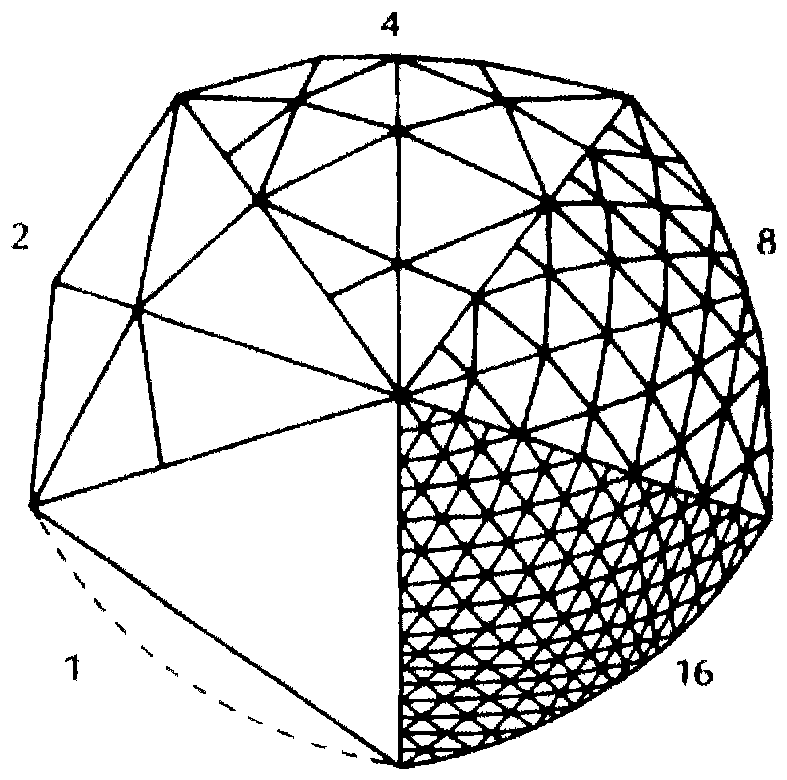

[0032] Attached below Figure 4-18 , to describe in detail the specific embodiments of the present invention.

[0033] The large-space metal spherical shed reticulated shell structure suitable for equipment storage and transportation includes: a spherical crown-shaped main reticulated shell 1 and a thin foam metal shed. The spherical crown-shaped main reticulated shell 1 is composed of a main body node seat, a base node seat 2, and a joint connecting rod 3, and the two are connected by threads. Its topological shape is obtained by establishing a plane primitive based on a 32-hedron, subdividing a regular hexagonal grid, selecting specific grid subdivision parameters, and performing topological mapping transformation to a spherical surface through grid nodes.

[0034] In the connection design of the spherical main reticulated shell structure, the joints of each main body node seat 2 are connected with three joint connecting rods 3, all pointing to the direction of the spherica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com