Mica Calcination Production Line

A mica calcination and production line technology, applied in the direction of inorganic chemistry, non-metallic elements, silicon compounds, etc., can solve the problems of mica heat not being collected, heat energy waste, etc., achieve good separation effect of sand and gravel, reduce energy consumption, and facilitate recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

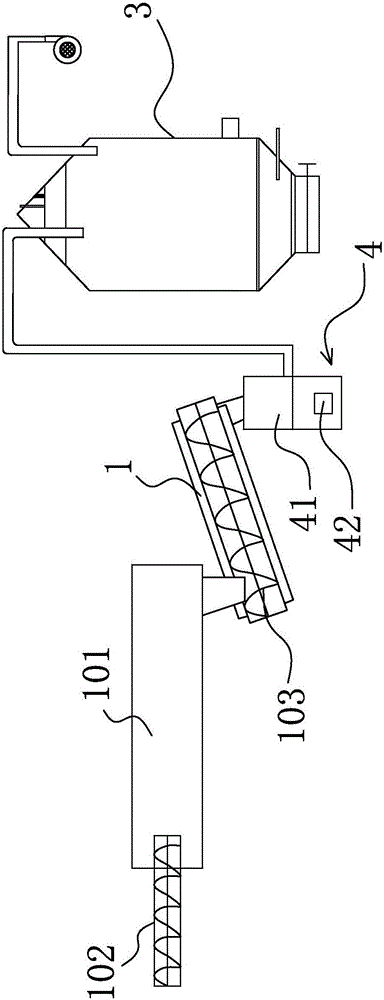

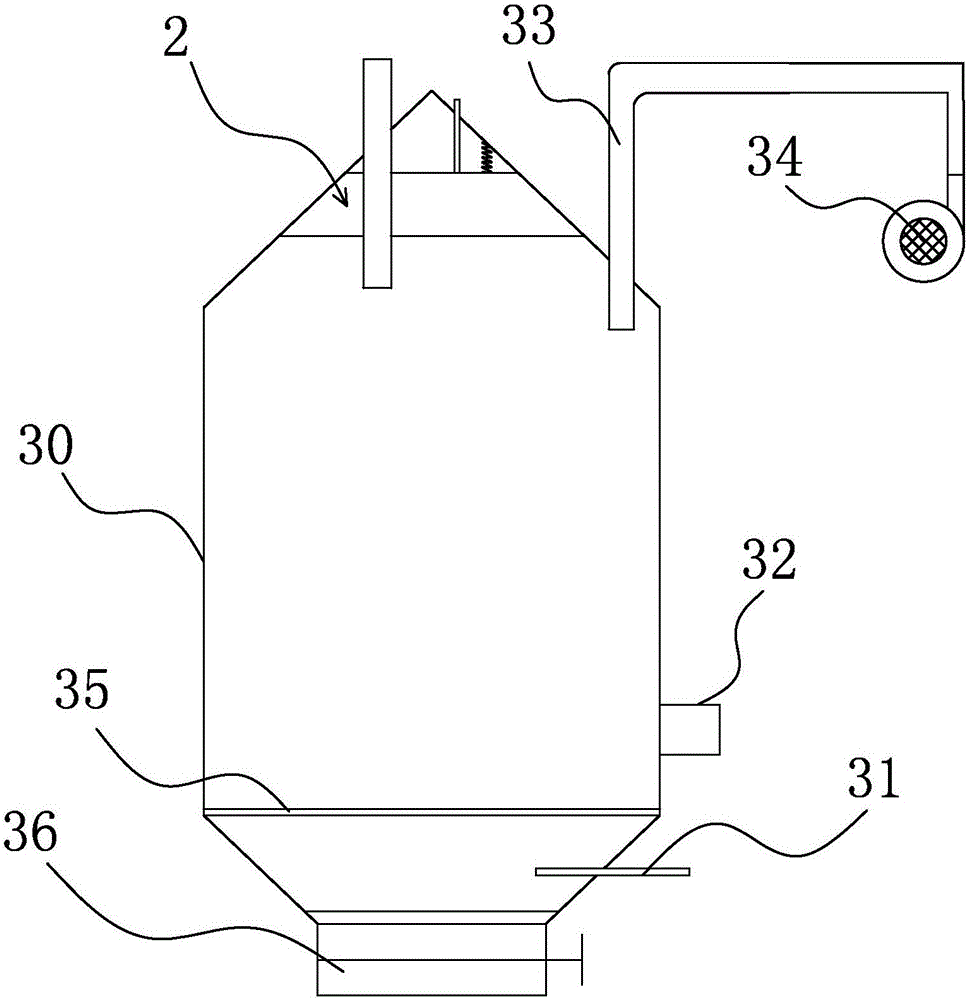

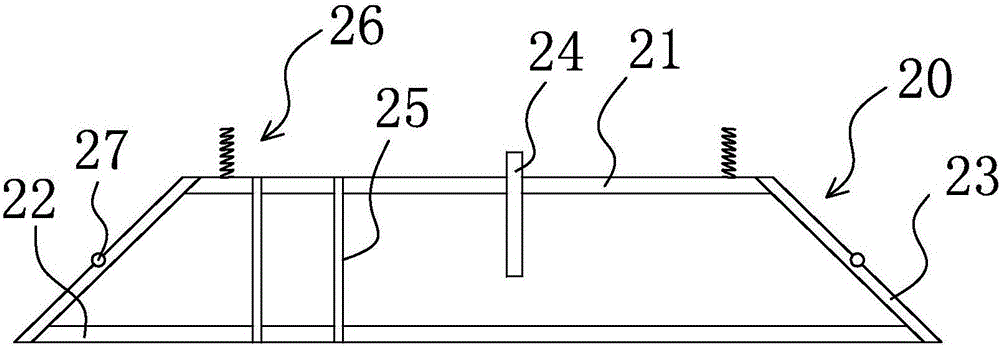

[0026] Such as Figure 1-5 As shown, a mica calcining production line includes a calciner 101, one end of the calciner 101 is connected to the first mica conveying mechanism 102, and the other end of the calciner 101 is connected to the second mica conveying mechanism 103, the The second mica conveying mechanism 103 is covered with a cooling jacket mechanism 1 capable of passing cooling water and cooling the mica in the second mica conveying mechanism 103 . The first mica conveying mechanism 102 and the second mica conveying mechanism 103 are preferably auger conveyors, which can withstand high temperatures. The present invention achieves the effect of waste heat recovery through the cooling jacket mechanism 1, thereby reducing energy consumption.

[0027] The cooling jacket mechanism 1 includes an inner sleeve 11 and an outer sleeve 12 with sealing plates 10 at both ends. The inner sleeve 11 is attached to the outer surface of the second mica conveying mechanism 103. The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com