A kind of preparation method of stable graphene colloidal dispersion liquid

A technology of olefin colloid and dispersion liquid is applied in the field of graphene preparation to achieve the effects of small particles, simple and easy preparation process, and easy control of reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

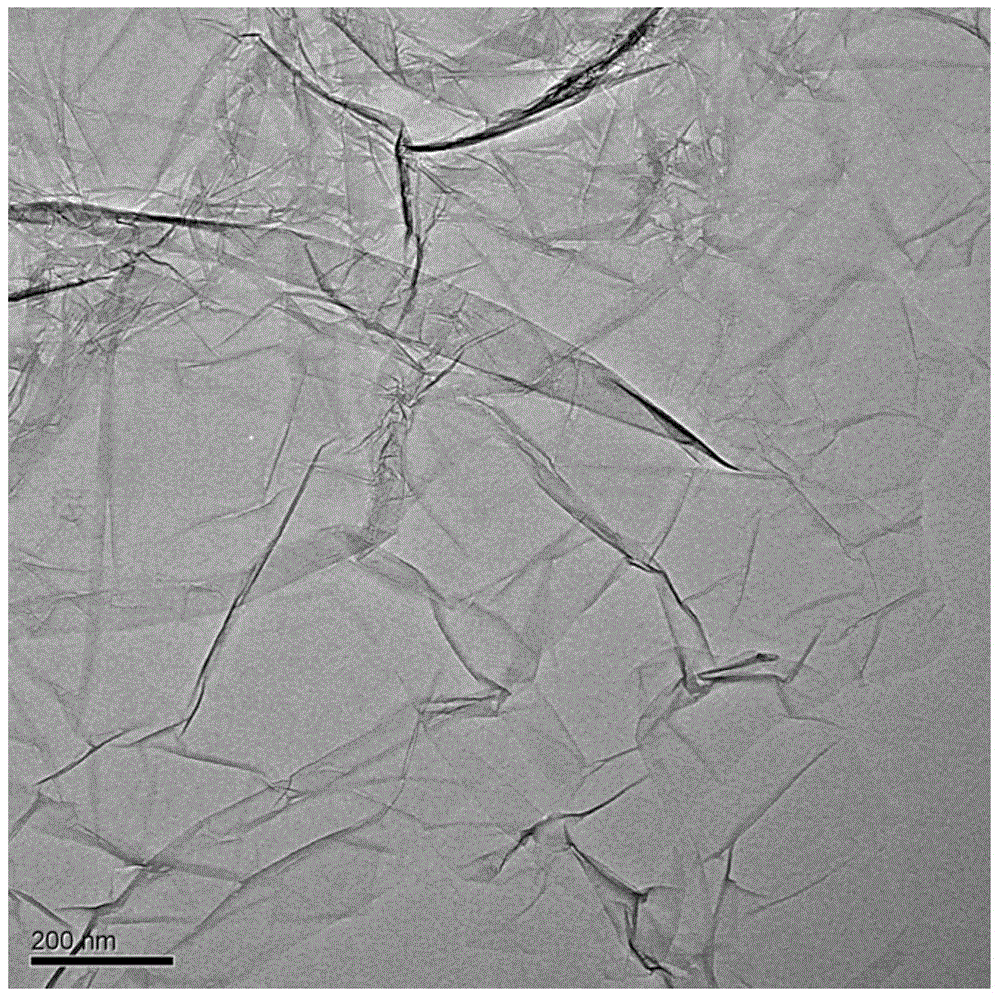

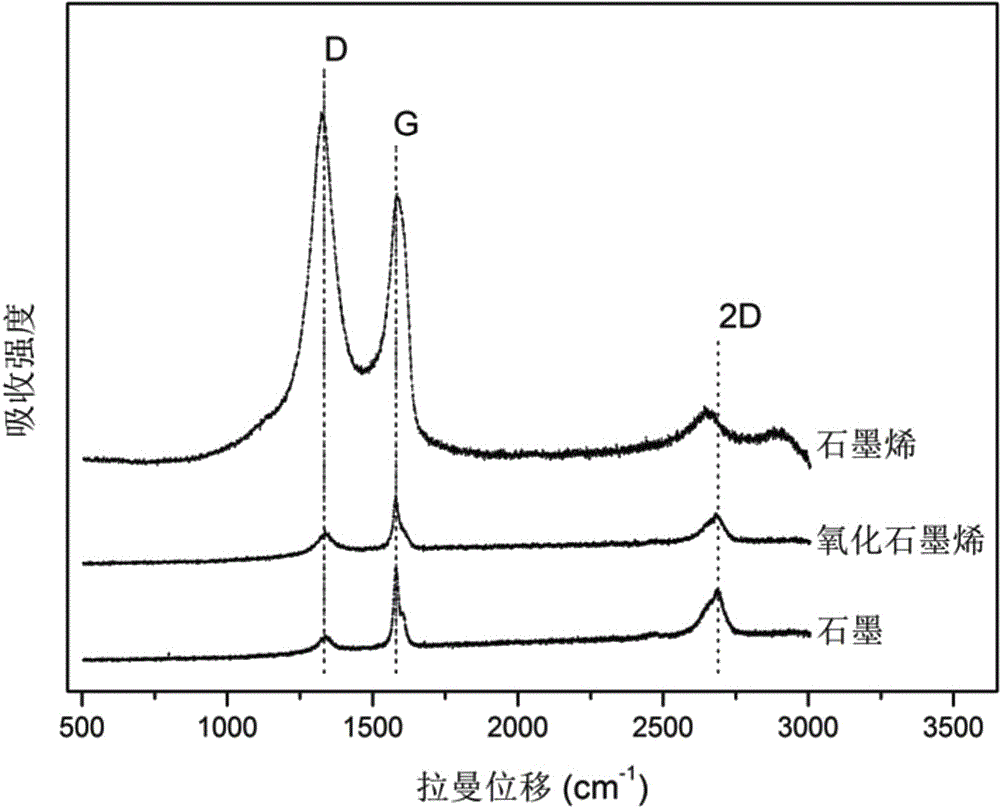

[0048] A method for preparing graphene dispersion liquid includes the following process steps:

[0049] Combine 1g, 99.85% by weight of graphite powder and 23mL, 98% by weight of H 2 SO 4 Mix in a 250mL beaker and stir at room temperature for 24 hours; in a 40℃ water bath, add 100mg, 99.0wt% NaNO to the beaker 3 And stir for 5min to make it fully dissolved. Slowly add 1500mg, 99.5wt% KMnO to the cup 4 , After adding in about 20min, control the reaction temperature below 5℃ and stir for 30min. Add 3 mL of distilled water to the beaker, wait for 5 minutes, then add 3 mL of distilled water, wait for 5 minutes, add 40 mL of distilled water, and stir for 15 minutes. Stop the water bath, add 140mL distilled water and 10mL, 30wt% H into the beaker 2 O 2 Stir at room temperature for 5 min to terminate the reaction. Centrifuge at 10000r / min for 4min using a centrifuge, wash with 5wt% HCl, and repeat twice. Then use a centrifuge at 8000r / min for 4 minutes, and wash with distilled water t...

Embodiment 2

[0051] A method for preparing a stable graphene dispersion includes the following process steps:

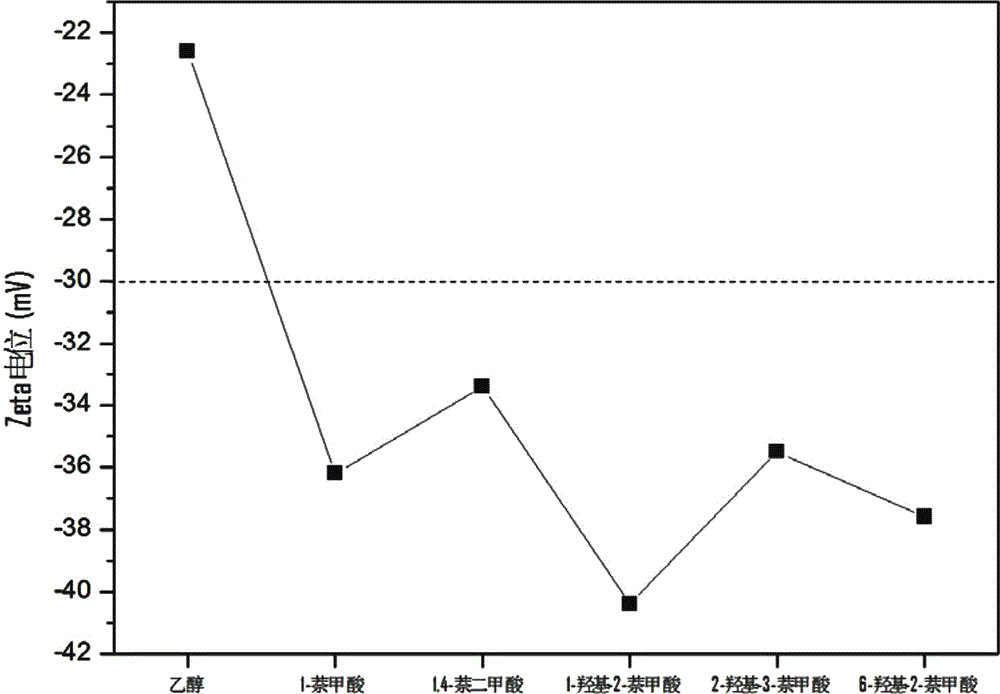

[0052] The graphene in Example 1 was dissolved in 100 mL, 99.7% by weight of ethanol, 70kHz ultrasonic for 30min peeled and dispersed, centrifuged at 12000r / min for 5min, washed with distilled water for 2 to 3 times to wash away residual ethanol. The precipitate was dispersed in 100 mL of distilled water, sonicated at 70 kHz for 30 min, and centrifuged at 10000 r / min for 5 min. The resulting supernatant was a dispersion with a concentration of 0.20 mg / mL and about 12 wt% of single-layer graphene. The prepared graphene dispersion does not have obvious Tyndall effect, its zeta potential is -22.6mV, and the average particle size of graphene is 720.5nm.

Embodiment 3

[0054] A method for preparing a stable graphene colloidal dispersion liquid includes the following process steps:

[0055] The graphene in Example 1 was dissolved in 100mL, 99.7wt% ethanol with 4mg, 98wt% 1-naphthoic acid, 70kHz ultrasonic for 30min peeling and dispersion, centrifuged at 12000r / min for 5min, and washed with distilled water 2-3 times , Wash away residual 1-naphthoic acid and ethanol. The precipitate was dispersed in 100 mL of distilled water, sonicated at 70 kHz for 30 min, and centrifuged at 10000 r / min for 5 min. The resulting supernatant was a colloidal dispersion with a concentration of 0.25 mg / mL and about 25 wt% of single-layer graphene. The prepared stable graphene colloidal dispersion has the Tyndall effect, its zeta potential is -36.2mV, and the average particle size of graphene is 387.3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com