Full-automatic coil winding mechanism for outputting cable

It is a fully automatic and disc-making machine technology, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials. It can solve the problems of inaccurate winding meters, high labor intensity, and slow processing speed, etc., and achieves convenience. The effect of operation, labor saving, and simple structure

Inactive Publication Date: 2014-07-23

STATE GRID CORP OF CHINA +3

View PDF5 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disc beating machine is a device used to process wires and cables into certain specifications. The traditional disc beating machine is generally operated manually, and the motor of the disc beating machine is manually stopped, and the outer baffle of the beating head is removed. , and then bundle the cables or wires, so that not only the processing speed is slow, the labor intensity of the workers is high, but also the number of meters of winding is not accurate, and the service life of the equipment is short

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

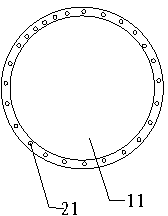

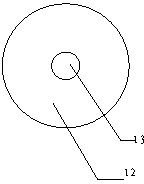

The invention provides a full-automatic coil winding machine for outputting a cable. The full-automatic coil winding mechanism for outputting the cable comprises a pay-off frame, a counting guiding cutting device, a coil winding machine and a PLC. After the cable penetrates through the counting guiding cutting device through the pay-off frame, the cable is connected with the coil winding machine for coil winding. The whole full-automatic coil winding mechanism is automated through control of the PLC. The full-automatic coil winding machine for outputting the cable is simple in structure, reasonable in design, capable of achieving full-automatic processing from pay-off to coil winding, free of manual operation, low in labor investment, low in cost and capable of greatly improving economical benefits and improving the product quality.

Description

technical field The invention belongs to power output equipment, and in particular relates to a disc machine, especially a fully automatic disc machine. Background technique The disc beating machine is a device used to process wires and cables into certain specifications. The traditional disc beating machine is generally operated manually. The motor of the disc beating machine is manually stopped, and the outer baffle of the beating head is removed. , and then bundle the cables or wires, not only the processing speed is slow, the labor intensity of the workers is high, but also the number of meters wound is not accurate, and the service life of the equipment is short. Contents of the invention In order to solve the above problems, the present invention provides a new type of disc beater that is fully automatic, has high work efficiency, and requires less labor input. In order to achieve the above object, the present invention is achieved through the followi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65H49/32B65H57/14B65H61/00B65H63/08

Inventor 周军

Owner STATE GRID CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com