An integrated powder color 3D printer

A 3D printer and integrated technology, applied in the field of powder 3D printers, can solve problems such as complicated operation and control process, unfavorable follow-up operation of parts, and large equipment volume, so as to facilitate safe transfer, save operation and control, and reduce workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

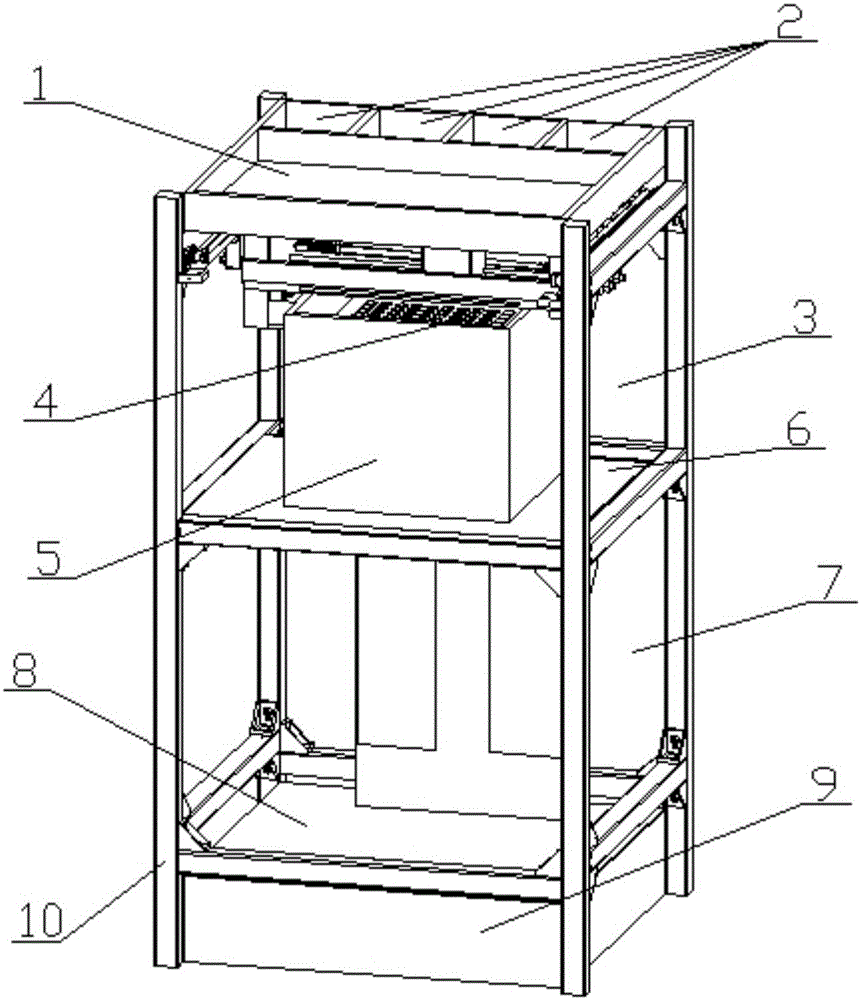

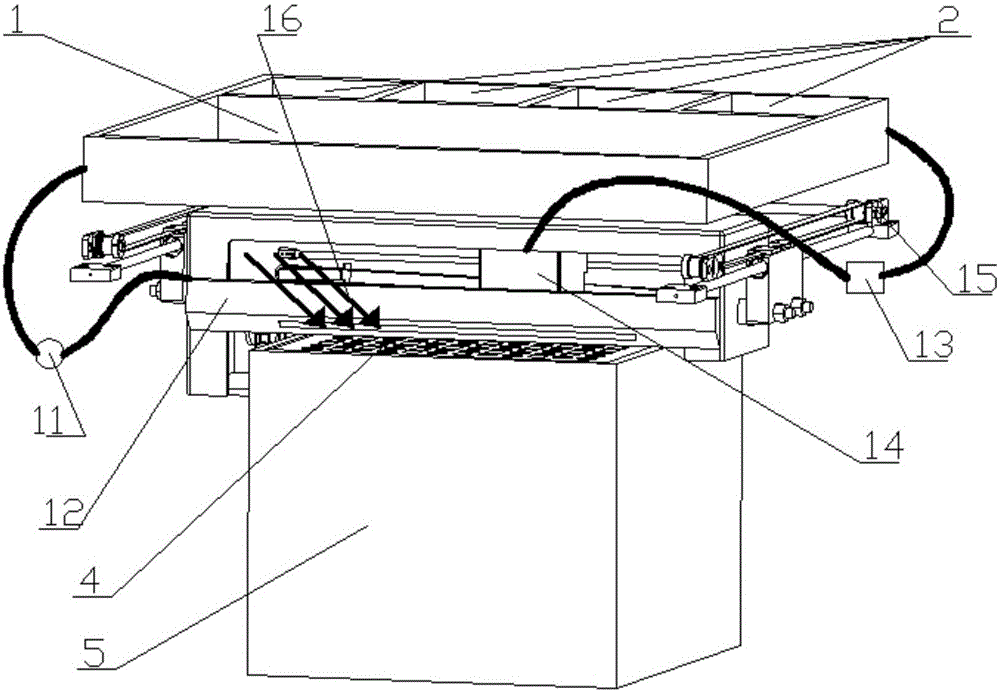

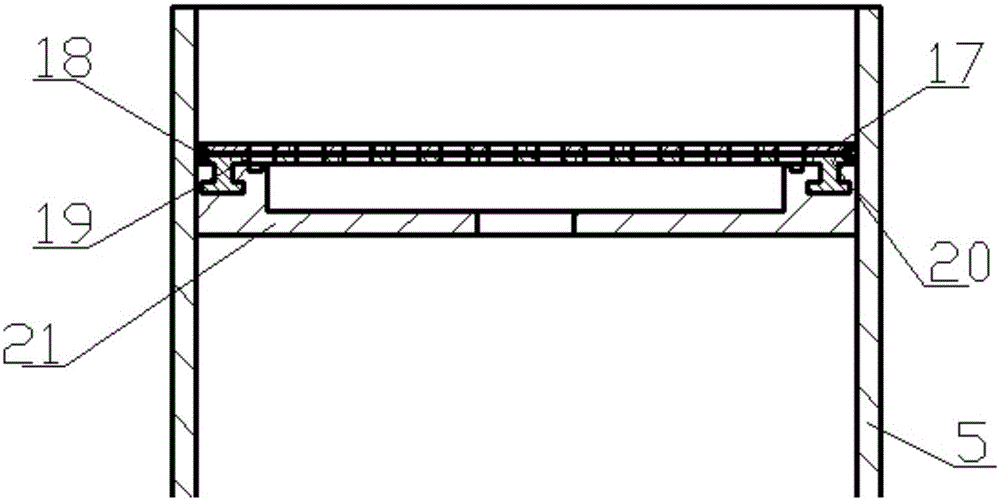

[0017] refer to figure 1 and Figure 4 , an integrated powder color 3D printer, including a frame 10, the top of the frame 10 is a powder storage tank 1 and an external supply binder box 2, and the lower part of the powder storage tank 1 and the external supply binder box 2 is connected to a working chamber 3. The lower part of the working chamber 3 is connected to the sealed post-processing chamber 7 through the partition 6, and the lower part of the sealed post-processing chamber 7 is provided with a screen 8 and a powder recovery box 9, and the lifting device 22 is connected to the frame at the sealed post-processing chamber 7 10, the lifting device 22 is connected with the vacuum negative pressure pallet 4, and the vacuum negative pressure pallet 4 moves up and down in the powder box 5 in the sealed post-processing chamber 7 and the working chamber 3 fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com