Adjustable fast-replacement type gold grain punching die

A punching die and quick-change technology, applied in the field of adjustable quick-change gold die punching die, can solve problems such as the inability to comprehensively improve the quality and production efficiency, the burrs of evaporated gold particles, and the inability to form mass supply. , to achieve the effect of good weight consistency, low operating cost and single grain weight control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

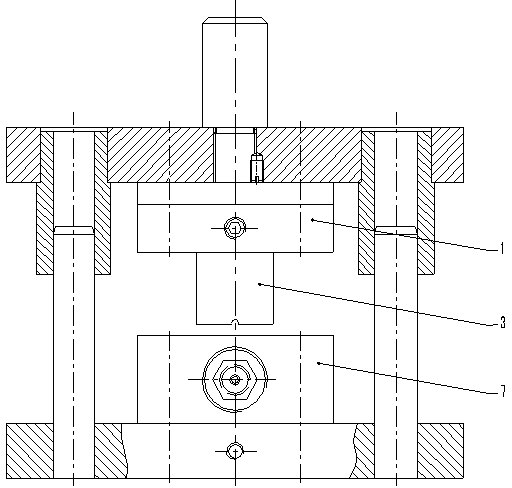

[0018] Such as Figure 1-2 As shown, the present invention is made up of an upper die with a punching blade 3 and a lower die with a limit block 9 and a punching bottom die 5, the upper die also includes a blade fixing plate 1, and the lower die also includes a bottom die Die fixing plate 7. The present invention must be matched with stamping machine tools. Before using the punching, the mold is closed, and the adjusting screw sleeve 6 is rotated to adjust the gap between the punching bottom die 5 and the punching blade 3 to be nearly zero. Open the mold, feed in the gold wire, and adjust the limit length to meet the requirements by trial cutting and turning the adjusting screw plug 8.

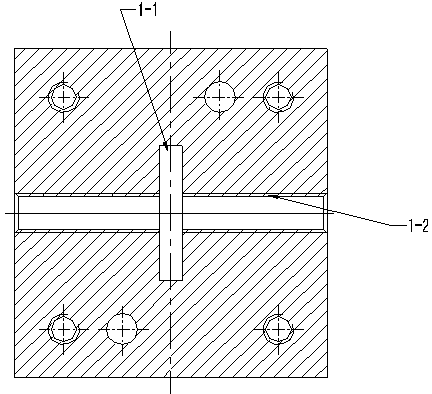

[0019] Such as figure 1 with 3 As shown, the center of the blade fixing plate 1 is provided with a clamping hole 1-1, and the two sides are provided with threaded through holes 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com