Working platform for offshore wind energy plant and method for manufacturing same

A technology for working platforms and wind energy devices, applied in wind power generation, manufacturing tools, engine manufacturing, etc., can solve problems such as anti-corrosion, high maintenance costs, cost and time consumption in complex assembly work of working platforms, and achieve flexible design or structure, The effect of cost saving and flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

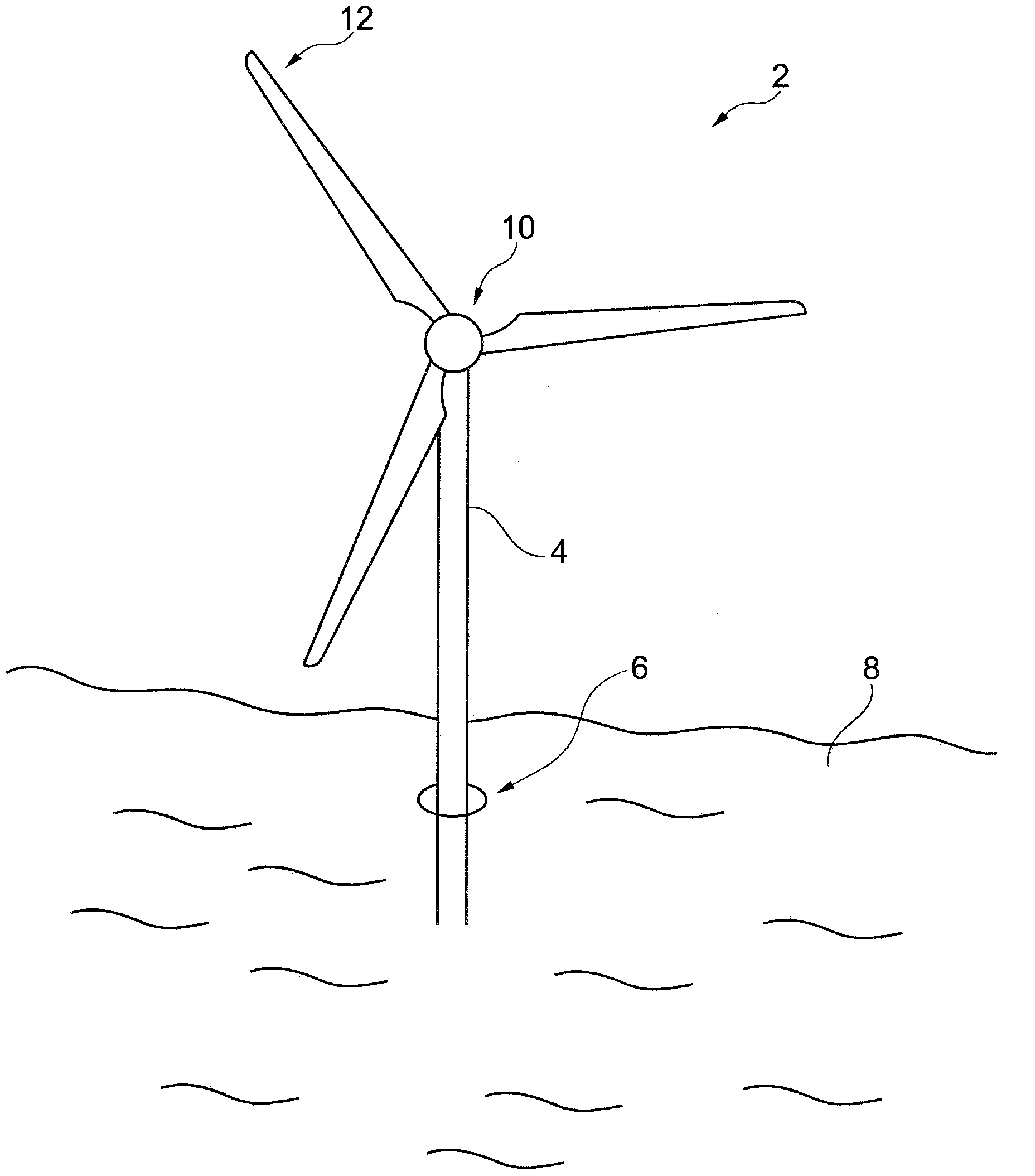

[0037] figure 1 It is a simplified offshore wind energy installation 2 with a tower 4 and a working platform 6 . The tower 4 is built on a suitable submerged foundation in the sea 8 and carries a hub 10 which itself carries the rotor blades 12 . During erection of the tower 4, several tower segments are assembled offshore.

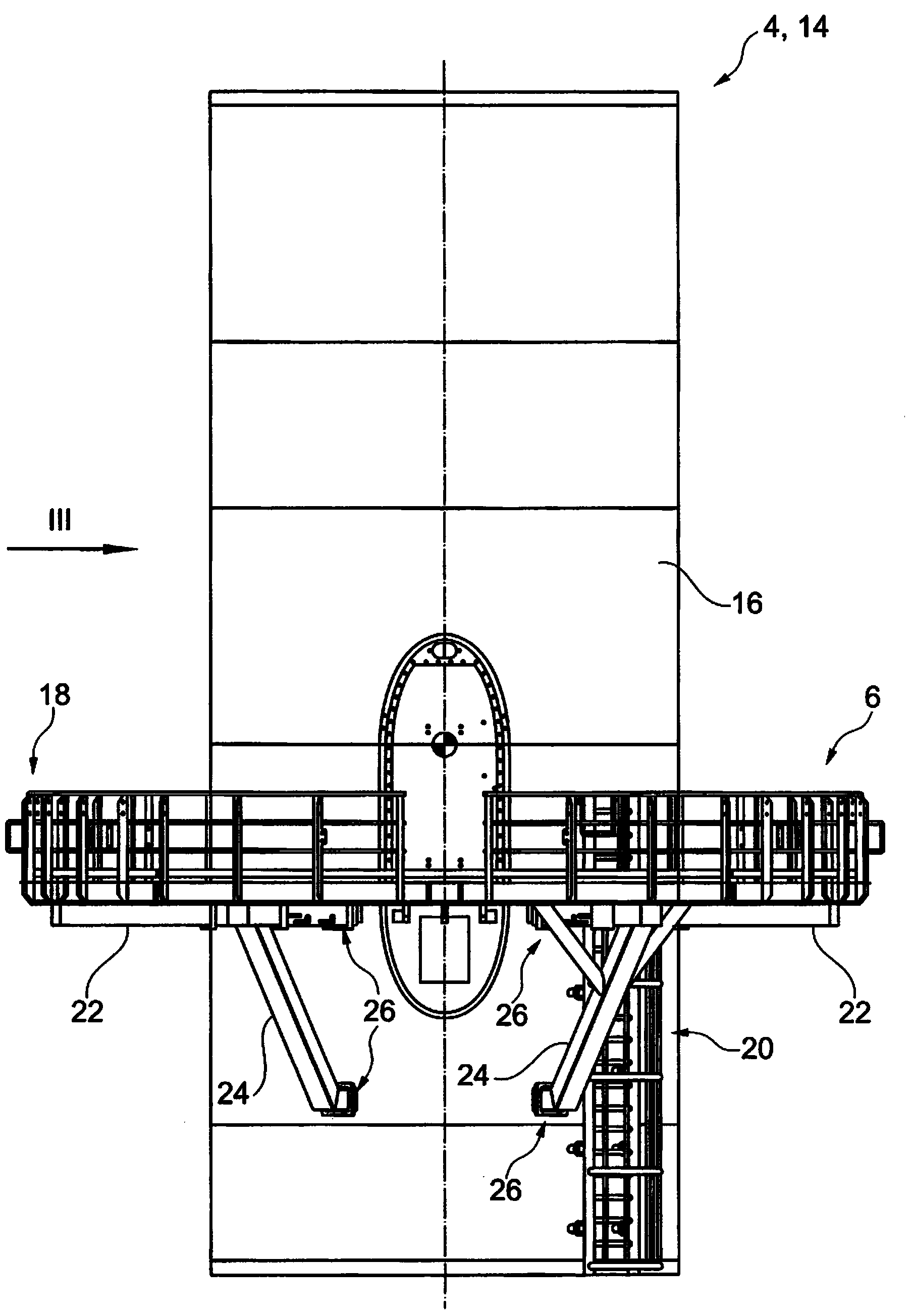

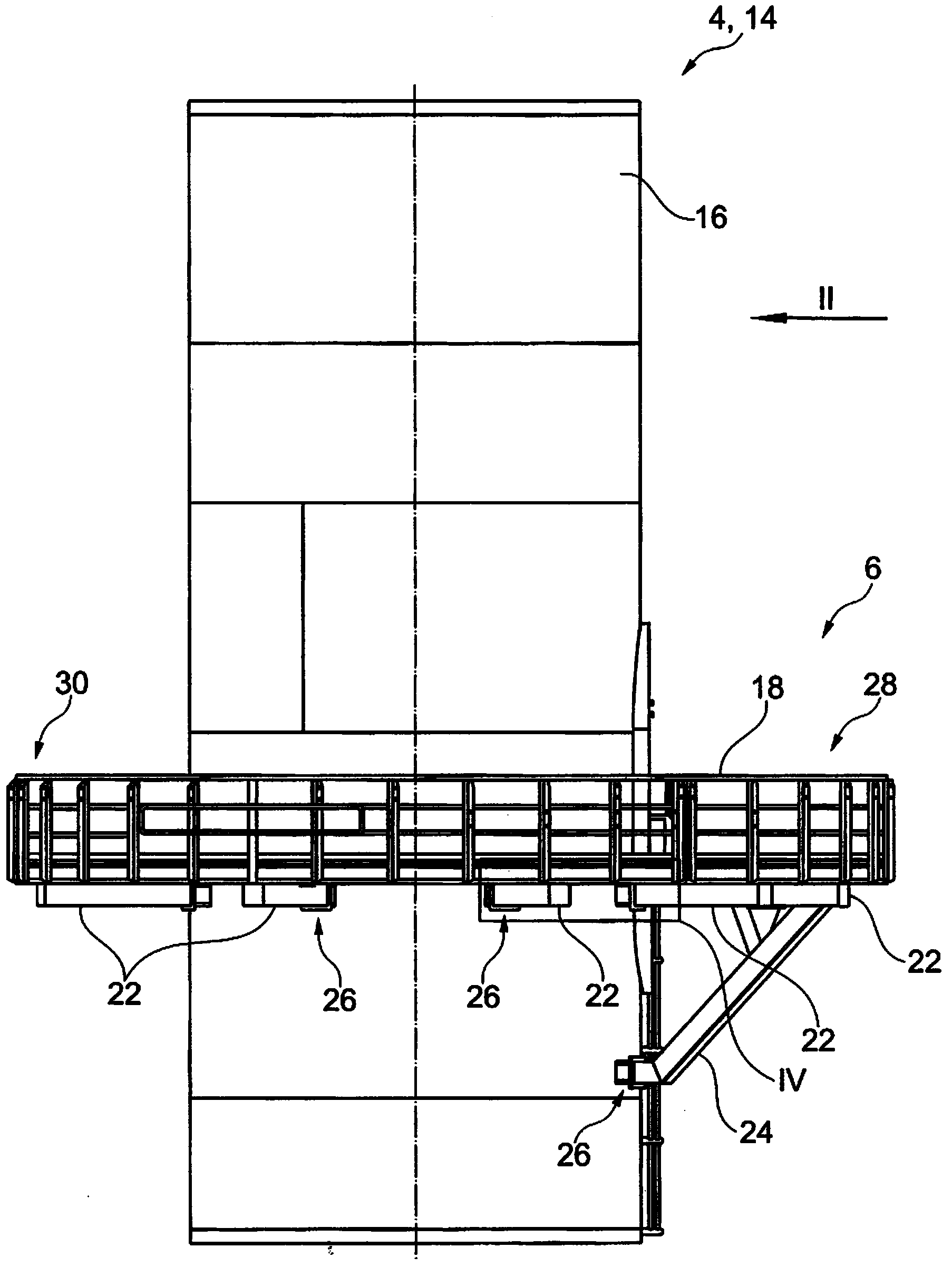

[0038] figure 2 There is shown a tower segment 14 and a working platform 6 welded to the tower 4 and the outer wall 16 of the tower segment 14 respectively. The work platform 6 includes a safety handrail 18 surrounding the work platform 6 at its periphery. The working platform 6 is accessible via an ascending ladder 20 which is also welded to the wall 16 of the tower segment 14 . The service engineer can access the wind energy installation 2 via the working platform 6 using the ascending ladder 20 . The working platform 6 is fixed to the tower segment 14 via radial beams 22 which are part of the load-bearing structure of the working platform 6 . For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com