Small high-power microwave amplification module based on strip line mode

A technology of microwave amplification and stripline, which is applied in the direction of power amplifiers, amplifiers, components of amplification devices, etc., can solve the problems of large electromagnetic radiation of high-power microwave amplification modules, achieve enhanced electromagnetic compatibility, solve electromagnetic leakage, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

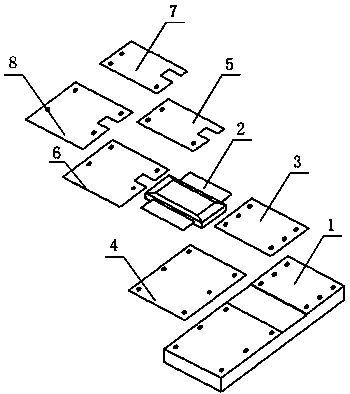

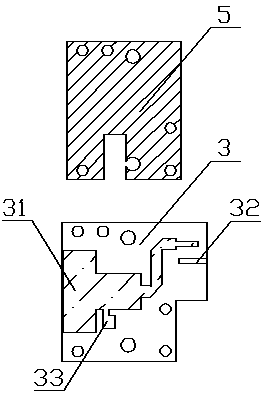

[0021] Such as figure 2 As shown, a small high-power microwave amplifying module based on the strip line method, which includes a substrate 1 with a groove, a power transistor 2 installed in the groove, printed with an input impedance matching unit 31 and an input transfer unit The bottom plate A3 of the input matching circuit composed of 32, the bottom plate B4 printed with the output matching circuit composed of the output transfer unit 42 and the output impedance matching unit 41, the cover plate A5, the cover plate B6, the feed circuit A and the feed circuit B, the bottom plate A3 and the bottom plate B4 are fixedly installed on the base plate 1; the cover plate A5 is pressed on the input impedance matching unit 31 and is firmly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com