Dust removal guide rail for semi-automatic winding machine

A winding machine, semi-automatic technology, applied in the direction of assembling battery machines, electrochemical generators, electrical components, etc., can solve problems affecting battery safety, etc., and achieve the effect of reducing battery short-circuit and assembly defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

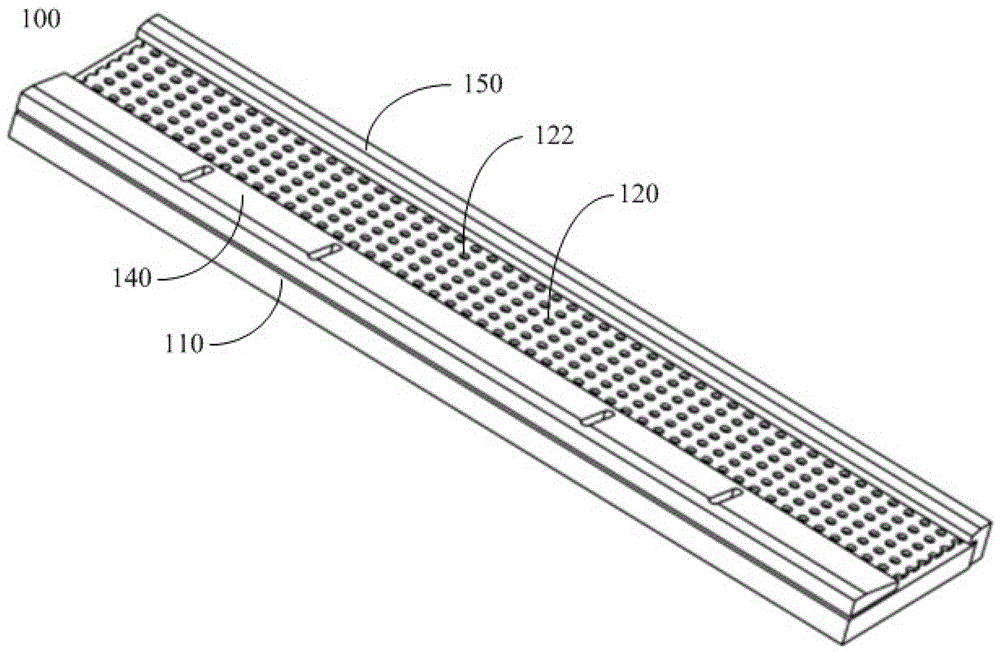

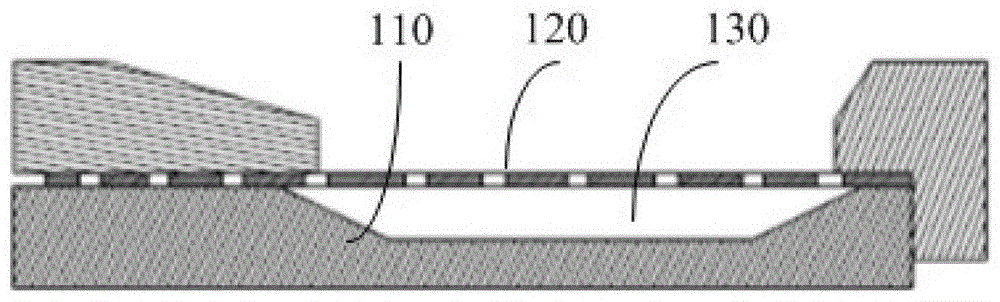

[0024] see figure 1 , a dust removal guide rail 100 for a semi-automatic winding machine, including a bottom plate 110 and a mesh plate 120 . The mesh plate 120 is installed on the bottom plate 110, and the mesh plate 120 is evenly opened with a plurality of mesh holes, and the bottom plate 110 is provided with a storage tank 130, the opening of the storage tank 130 is facing the mesh plate 120, and the storage tank 130 For collecting dust particles.

[0025] Specifically, the dust removal guide rail 100 of the semi-automatic winding machine can be driven to work by a battery, or can be driven to work by other power devices such as a motor. The positive electrode sheet and the negative electrode sheet of the lithium ion battery are sent into the winding mechanism through the dust removal guide rail 100 of the semi-automatic winding machine and wound with the separator to form a core.

[0026] Please also refer to figure 2 , the bottom plate 110 may be a cuboid or other sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com